Treatment method of fused salt chlorination slag

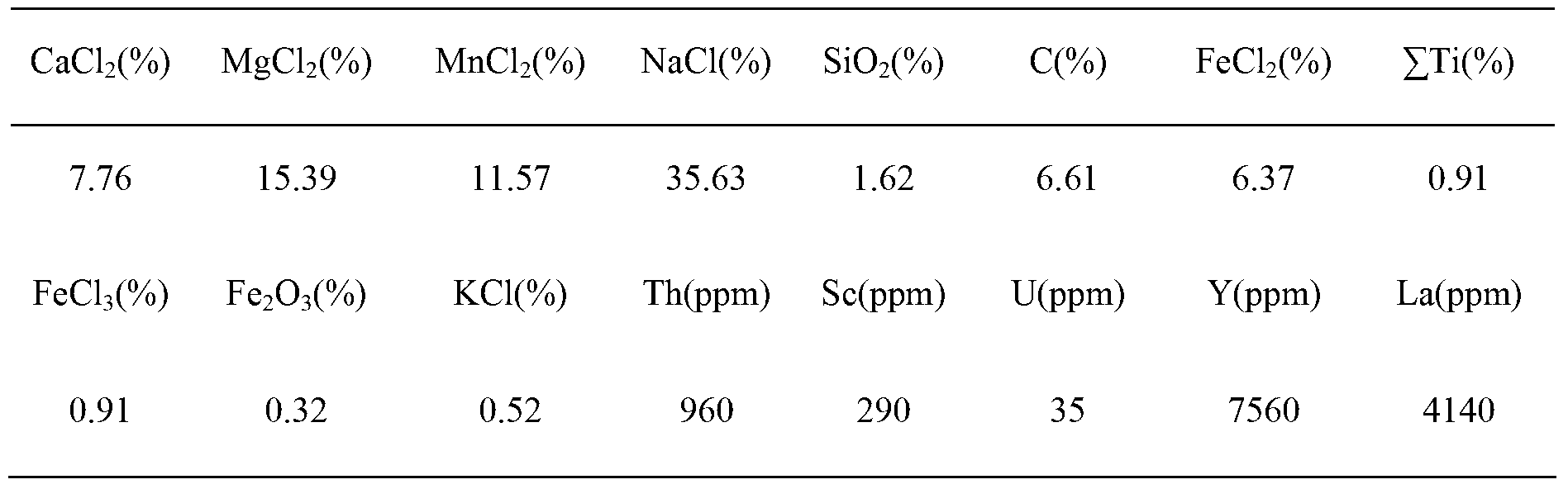

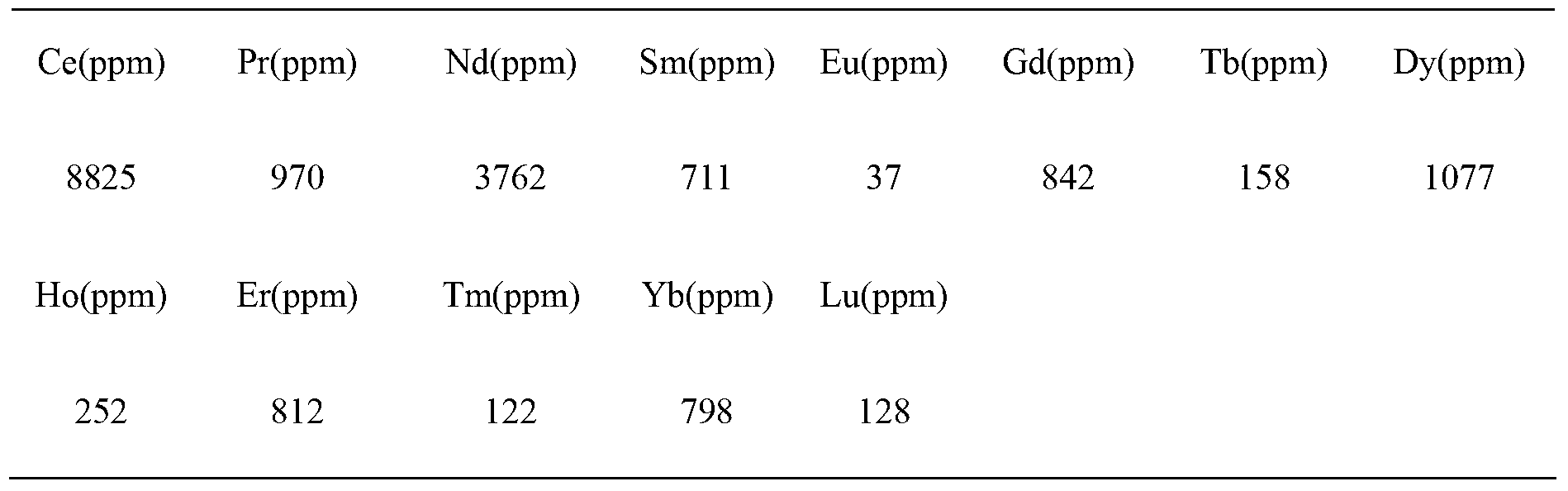

A technology of molten salt chloride slag and treatment method, which is applied in the field of hydrometallurgy and can solve the problems of eliminating the comprehensive recycling and utilization of molten salt chloride slag without considering radioactivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1.1 Mix 200g of molten salt chloride slag with 500ml of 0.5mol / L HCl, stir at room temperature for 1 hour, and filter to obtain 480ml of leaching solution and leaching residue. After the leaching residue is incinerated, the residue amount is 4.3g.

[0055] 1.2 Mix 1ml 2-ethylhexylphosphonic acid mono-2-ethylhexyl ester (P507) with 99ml sulfonated kerosene to obtain a blank organic phase I as the extractant, 0.5mol / L HCl as the washing acid, 0.2mol / L NaOH As a stripping agent, extract, wash, and strip the leachate obtained in 1.1 in sequence. In the separation process, a 30ml separatory funnel was used as the reactor, and the shaking time was 10min. The flow ratio of blank organic phase I, leachate, washing acid and stripping agent in the separation process is 5ml: 25ml: 1ml: 1.5ml; the sequence ratio of extraction, washing and stripping in the separation process is 1:5:1. Obtain raffinate I, washing solution and stripping solution I, mix and treat the obtained washing ...

Embodiment 2

[0060]2.1 Mix 200g of molten salt chloride slag with 2000ml of water, stir at room temperature for 1 hour, and filter to obtain 2010ml of leaching solution and leaching residue. After the leaching residue is incinerated, the residue amount is 4.0g.

[0061] 2.2 Add alkali to adjust the pH value of the leaching solution obtained in 2.1 to 5.5, filter to obtain the precipitation tail liquid and precipitation residue, the precipitation tail liquid is evaporated and crystallized to obtain industrial salt; the precipitation residue is dissolved with hydrochloric acid to obtain feed liquid I.

[0062] 2.3 Mix 50ml P507 with 50ml sulfonated kerosene to obtain a blank organic phase I as the extractant, use 5mol / L HCl as the washing acid, and 4mol / L NaOH as the stripping agent to extract, wash and wash the liquid I obtained in 2.2 in sequence back extraction. In the separation process, a 30ml separatory funnel was used as the reactor, and the shaking time was 10min. The flow ratio of ...

Embodiment 3

[0066] 3.1 Mix 200g of molten salt chloride slag with 600ml of 0.5mol / L HCl, stir at room temperature for 1 hour, and filter to obtain 590ml of leaching solution and leaching residue. After the leaching residue is incinerated, the residue is 4.1g.

[0067] 3.2 Add alkali to adjust the pH value of the leaching solution obtained in 3.1 to 6, filter to obtain the precipitation tail liquid and precipitation residue, the precipitation tail liquid is evaporated and crystallized to obtain industrial salt; the precipitation residue is dissolved with hydrochloric acid to obtain feed liquid I.

[0068] 3.3 Mix 5ml P204 with 95ml sulfonated kerosene to obtain a blank organic phase I as the extractant, use 0.5mol / L HCl as the washing acid, and 4mol / L NaOH as the stripping agent to extract and wash the material liquid I obtained in 3.2 in sequence with stripping. In the separation process, a 30ml separatory funnel was used as the reactor, and the shaking time was 10min. In the separation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com