Heavy metal ion negative pressure cavitation adsorption method

A technology of heavy metal ions and negative pressure cavitation, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment, etc., can solve the problems that it is difficult to achieve the desired effect and meet the needs of large-scale wastewater treatment. Achieve the effects of eliminating radioactivity in wastewater, strong applicability, and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

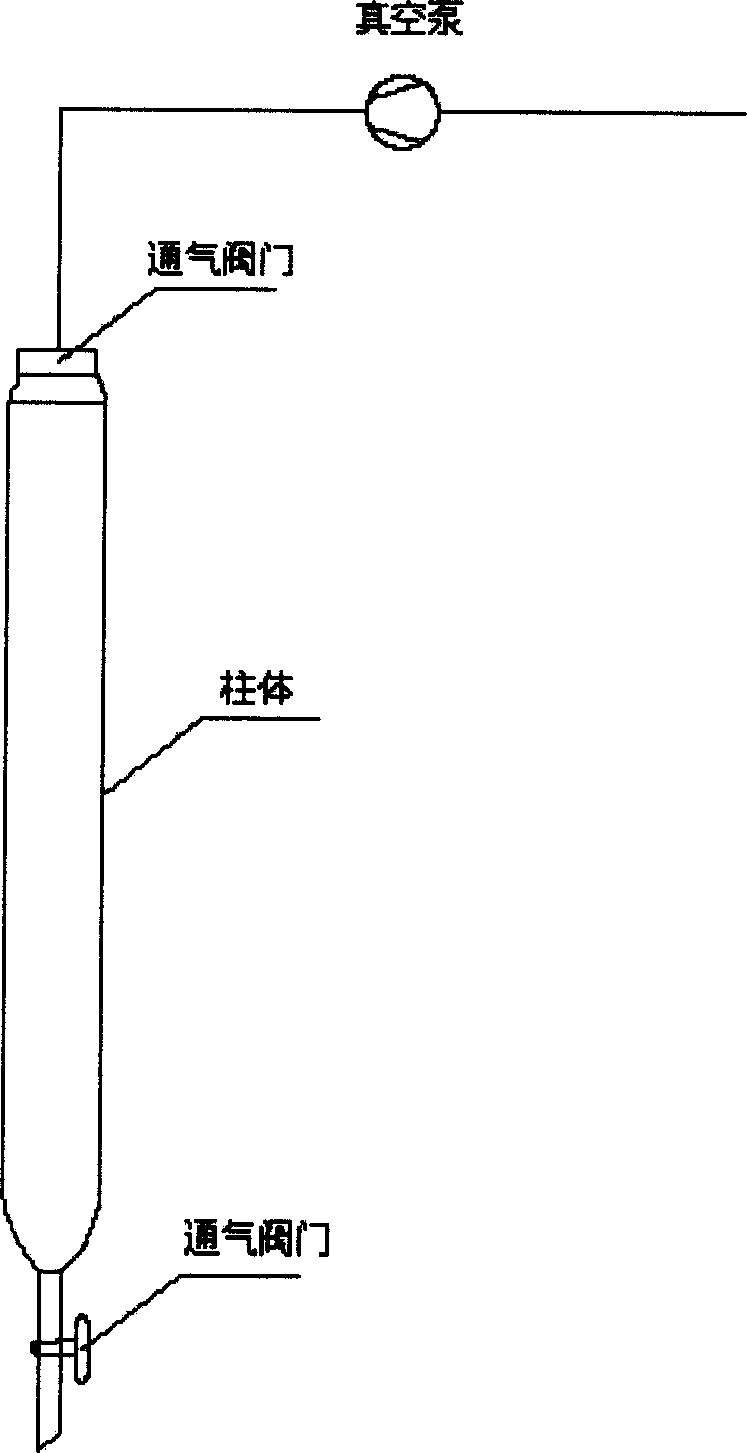

[0016] Example 1: At room temperature, take 2 cavitation columns shown in Figure 1 and add the yeast suspension equivalent to 0.6g of dry yeast. Turn on the vacuum button to pump negative pressure, and at the same time, open the air inlet valve at the bottom of the cavitation column to start feeding Material, inhaled 200mL 50mg / L CuSO 4 Solution, after sampling, control the ventilation of one of them to 0.002m 3 / h, the negative pressure is -0.08MPa, perform small aeration and agitation adsorption, after 10 minutes, keep the negative pressure unchanged, and increase the ventilation to 0.12m 3 / h, negative pressure cavitation adsorption, after 50 minutes of adsorption, centrifugal separation of the yeast after adsorption of heavy metals, add 60ml of pH 0.7 water, control the negative pressure to -0.08MPa, and the air volume to 0.2m 3 / h for elution of heavy metals for 30 minutes, after elution, yeast can re-adsorb heavy metals. Control the ventilation of another cavitation column a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com