Method for treating cellulose acetate butyrate production wastewater

A technology for acetic acid butyric acid and waste water production, which is applied in the fields of natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of large amount of sludge, complicated treatment process and high operating cost , to achieve the effect of reducing operating costs, good treatment effect and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

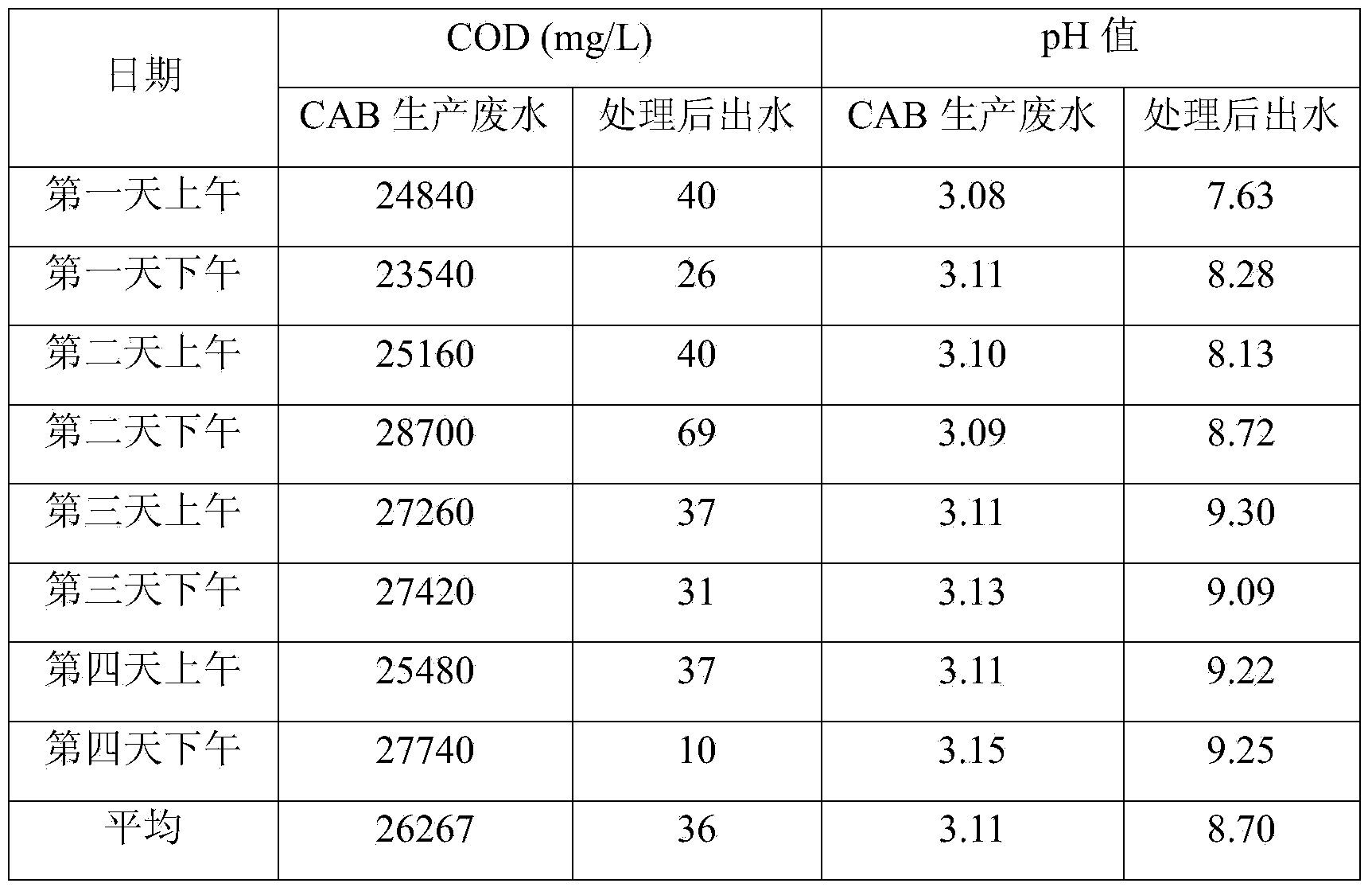

[0060] Taking the CAB production wastewater discharged from a factory as the treatment object, its parameters before treatment are: COD=18000~30000mg / L, BOD=14000~16000mg / L, B / C≈0.625, sulfate=4000~5000mg / L , pH=3.0~3.2.

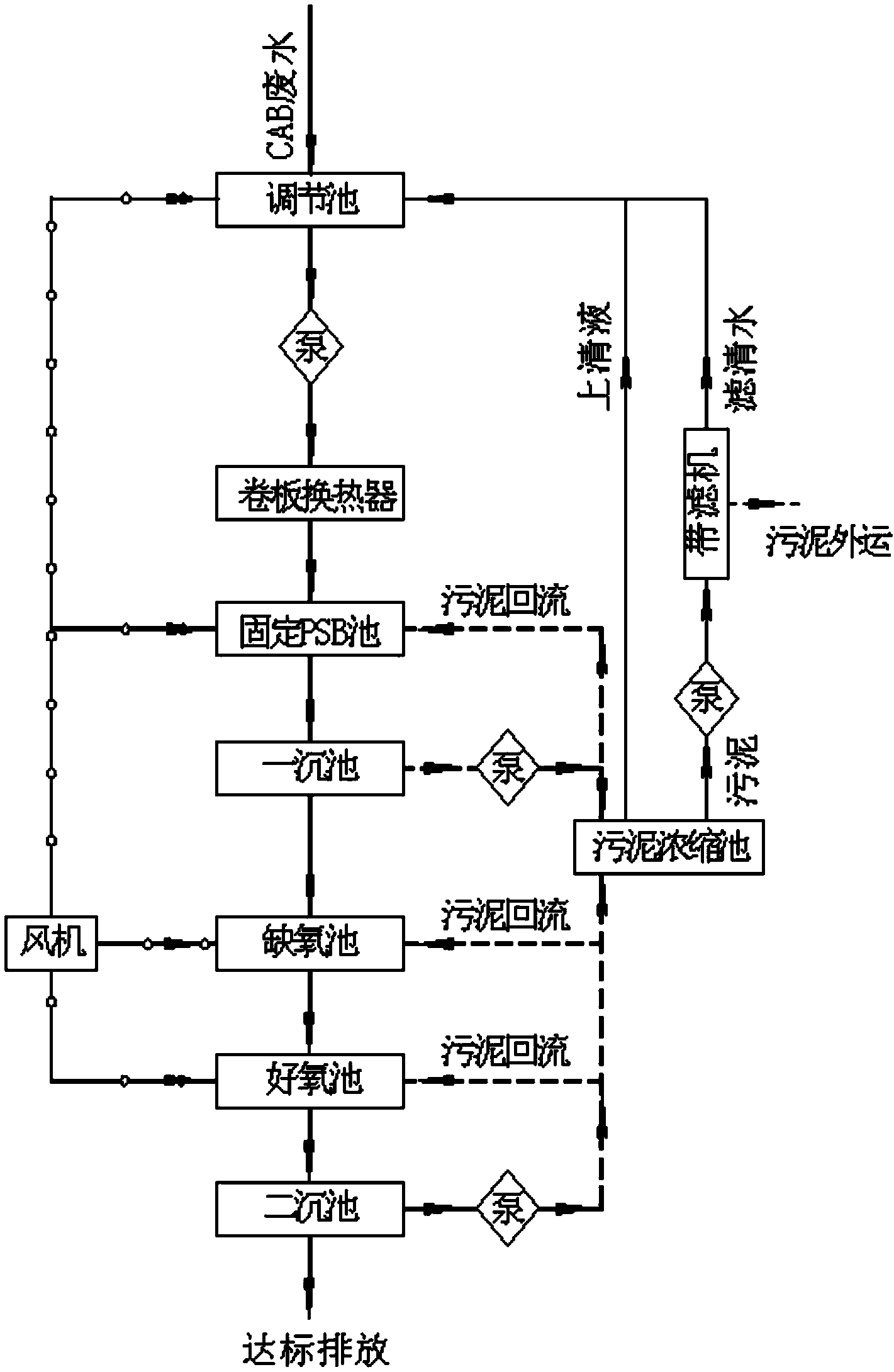

[0061] Adopt device and method of the present invention to carry out combined treatment to above-mentioned CAB production waste water; Concrete treatment process is as follows:

[0062] 1) The wastewater from the production line flows into the regulating tank through the pipe network. In order to ensure the uniformity of the wastewater, aeration and stirring are carried out in the tank. The gas-water ratio of the stirring is 2:1. The liquid is returned to the adjustment pool, the purified gas has reached the standard, and it is discharged at high altitude. If the water temperature in the regulating pool is higher than 45°C, it will be lifted into the plate heat exchanger to cool down and then flow into the immobilized photosynthetic bacteria pool; if the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com