Fused salt heat treatment method for rubbish incineration fly ash

A technology of waste incineration fly ash and heat treatment method, which is applied to chemical instruments and methods, solid waste removal, transportation and packaging, etc. It can solve the problems of high energy consumption, secondary pollution, high treatment temperature, etc., and achieve simple procedures and reduce secondary pollution. Secondary pollution, the effect of improving resource utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

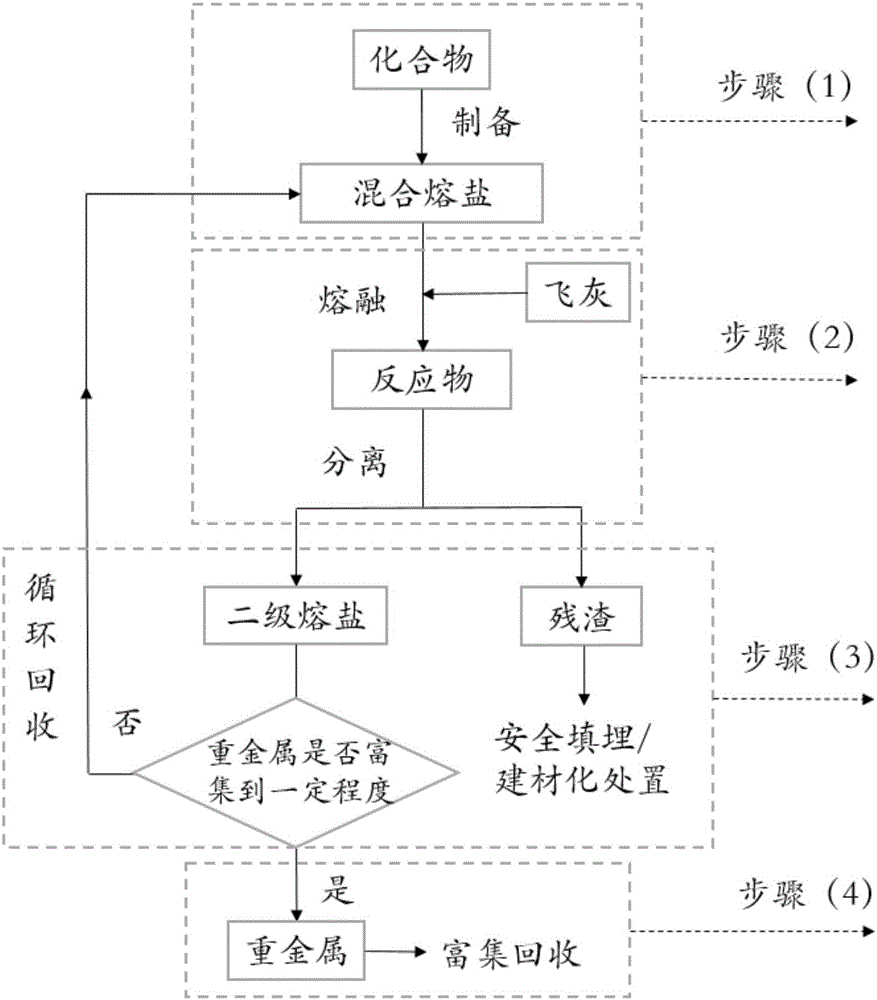

[0023] (1) The carbonate group is mixed, and then heated at 900°C to obtain mixed molten salt; the carbonate group is a mixture of 33.3% sodium carbonate, 33.3% potassium carbonate and 33.4% lithium carbonate by mass percentage ;

[0024] (2) Add garbage incineration fly ash to the mixed molten salt, carry out melting and heat treatment, and obtain the reactants through separation to obtain secondary molten salt and residue; the mass ratio of the mixed molten salt to garbage incineration fly ash is 10 : 1; melting heat treatment temperature is 850 ℃, and the time of heat treatment is 2h;

[0025] Test the residue quality and heavy metal content respectively;

[0026] (3) After the residue is treated, it is used as a building material or safely landfilled; for the secondary molten salt, check whether the content of Pb, Zn or Cu reaches 0.7%, 1%, or 0.4%, then proceed to step (4), otherwise it will be used as mixed molten salt and turn to step (2);

[0027] (4) Extraction and...

Embodiment 2

[0030] (1) The chloride salt group is mixed, and then heated at 400° C. to obtain mixed molten salt; the chloride salt group is 33.3% by mass percentage of sodium chloride, 33.3% of potassium chloride and 33.4% of chloride Calcium mixture;

[0031] (2) Add waste incineration fly ash to the mixed molten salt, carry out melting heat treatment, and obtain the reactant after separation to obtain secondary molten salt and residue; the mass ratio of the mixed molten salt to waste incineration fly ash is 3 : 1; Melting heat treatment temperature is 400 ℃, and the time of described heat treatment is 4h;

[0032] (3) After the residue is treated, it is used as a building material or safely landfilled; for the secondary molten salt, check whether the content of Pb, Zn or Cu reaches 0.7%, 1%, or 0.4%, then proceed to step (4), otherwise it will be used as mixed molten salt and turn to step (2);

[0033] (4) Extraction and recovery of heavy metals are carried out on the secondary molten...

Embodiment 3

[0036] (1) Mix the carbonate group and the chloride salt group, and then heat at 600° C. to obtain mixed molten salt; the mass percentage of the carbonate group and the chloride salt group is 60%: 40%;

[0037] The carbonate group is a mixture of 50% by mass of sodium carbonate and 50% of potassium carbonate, and the chloride salt group is a mixture of 50% by mass of sodium chloride and 50% of potassium chloride;

[0038] (2) Add waste incineration fly ash to the mixed molten salt, carry out melting heat treatment, the obtained reactants are separated to obtain secondary molten salt and residue; the mass ratio of the mixed molten salt to waste incineration fly ash is 20 : 1; melting heat treatment temperature is 600 ℃, and the time of described heat treatment is 10h;

[0039] Test the residue quality and heavy metal content respectively;

[0040] (3) After the residue is treated, it is used as a building material or safely landfilled; for the secondary molten salt, check whet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com