A high-efficiency energy-saving boiler

A high-efficiency energy-saving boiler technology, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of high exhaust gas flow rate, waste, energy waste, etc., and achieve the effect of avoiding emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

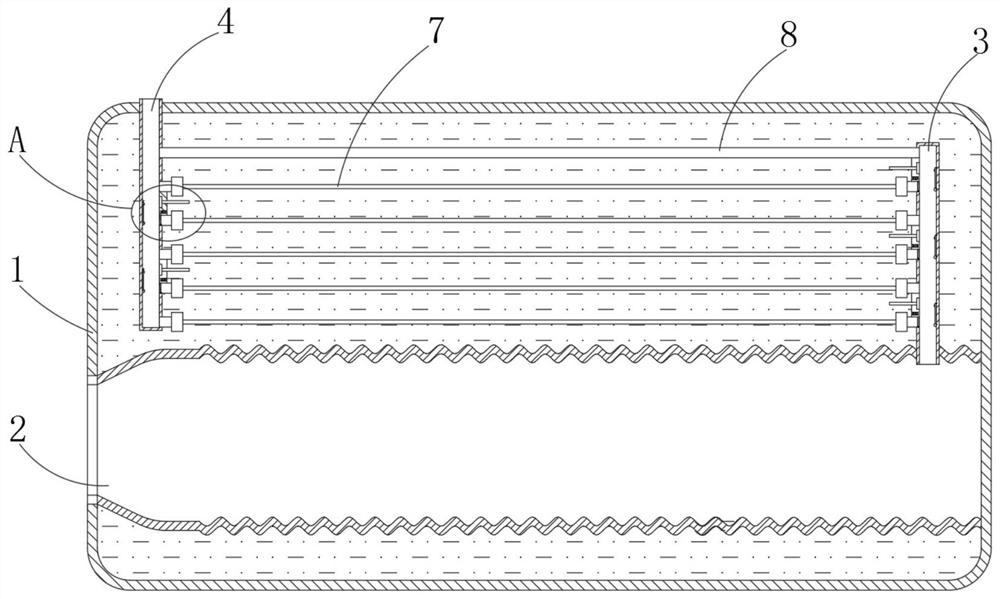

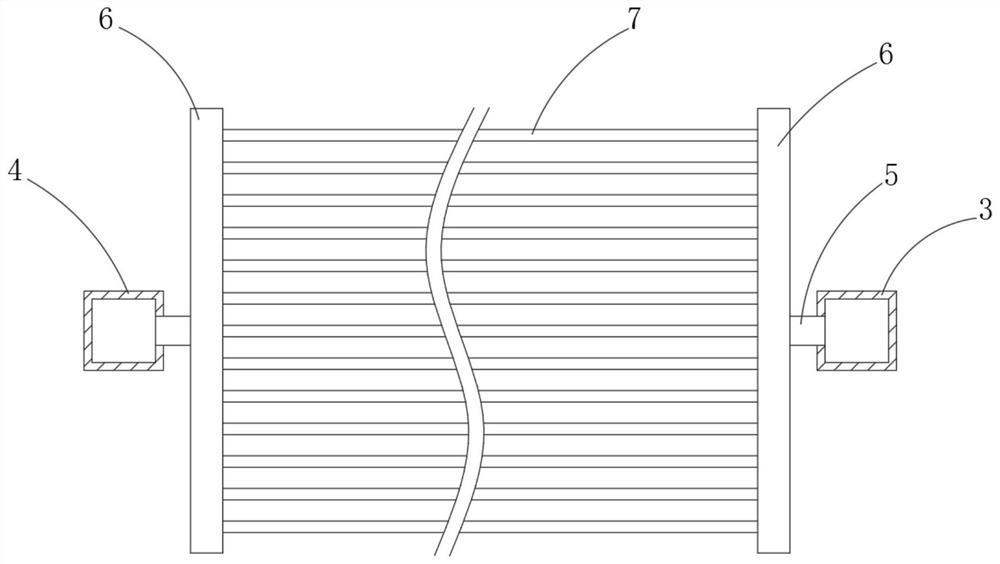

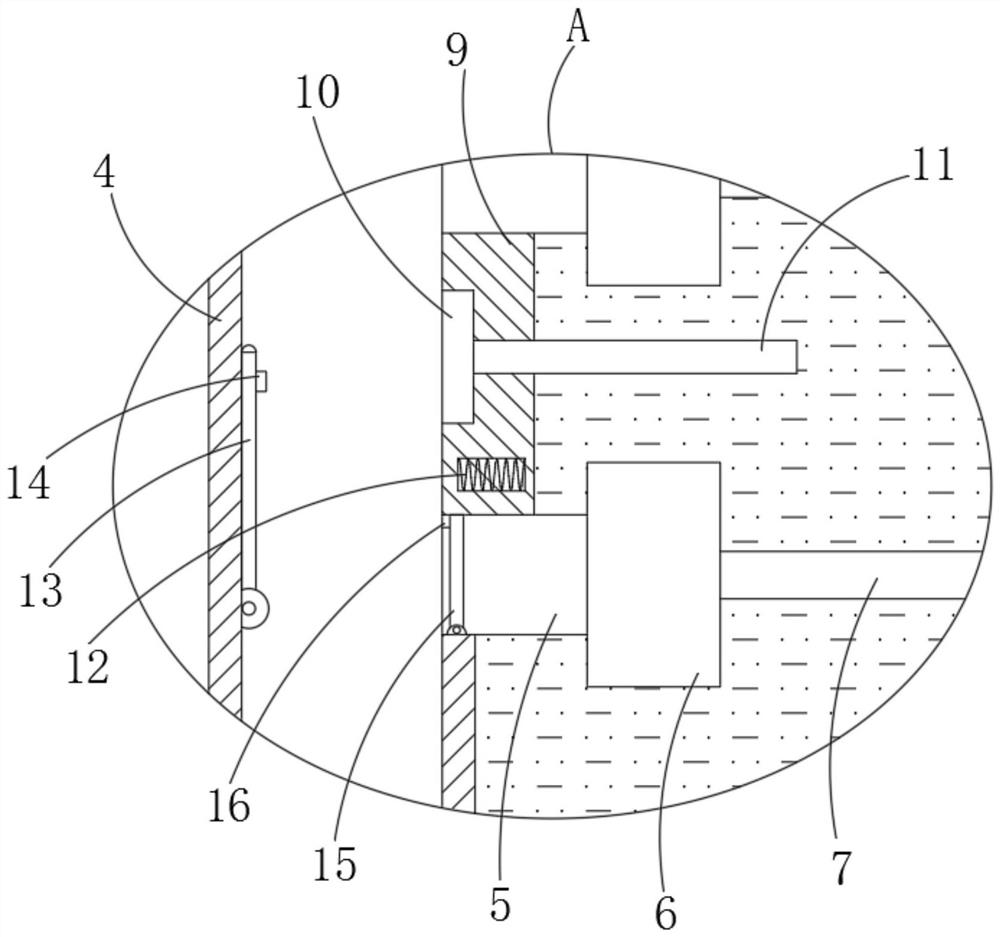

[0023] refer to Figure 1-3 , a high-efficiency energy-saving boiler, including a boiler body 1 and a furnace 2, the boiler body 1 is provided with a first vertical pipe 3 and a second vertical pipe 4, the lower end of the first vertical pipe 3 communicates with the furnace 2, the first vertical pipe The upper end of the pipe 3 is closed, the second vertical pipe 4 penetrates upwards through the outer wall of the boiler body 1, the lower end of the second vertical pipe 4 is closed, and the ends of the first vertical pipe 3 and the second vertical pipe 4 are fixed and communicated with a short Tube 5, each short tube 5 is fixedly connected with a shunt pipe 6, two shunt pipes 6 at the same height communicate with a plurality of metal heat-conducting pipes 7, the first vertical pipe 3 and the second vertical pipe 4 are connected with the The junction of the short tube 5 is provided with a plurality of automatic control devices, and the automatic control devices are alternately a...

Embodiment 2

[0034]The difference between this embodiment and Embodiment 1 is that the part of the second vertical pipe 4 located outside the boiler body 1 is sealed and connected with a horizontally arranged outer pipe 17. The cross section of the outer pipe 17 is a square structure, and the upper wall of the outer pipe 17 is fixed. A baffle 18 is connected, and a third rotating plate 19 is connected to the baffle 18 for damping rotation. The outer tube 17 is connected with a return pipe 20 .

[0035] It is difficult to ensure the complete combustion of fuel during the combustion process of the boiler, so that the air flowing out of the second standpipe 4 contains a certain amount of combustibles such as carbon monoxide, and at the same time, there are non-combustible gases such as carbon monoxide whose molecular weight is smaller than that of carbon dioxide and sulfur dioxide, so that carbon monoxide There is a tendency to move upwards, so when the air flowing out of the second vertical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com