Turbulent bar structure for drying cylinder with functions of high efficiency and energy saving

A technology for spoiler rods and drying cylinders is applied in the field of spoiler rod structures for high-efficiency and energy-saving drying cylinders, which can solve the problem of unreasonable number and size of strip spoiler rods, poor paper drying effect, and increase the production cost of manufacturers. and other problems, to achieve the effect of scientific and reasonable number and size, simple structure, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

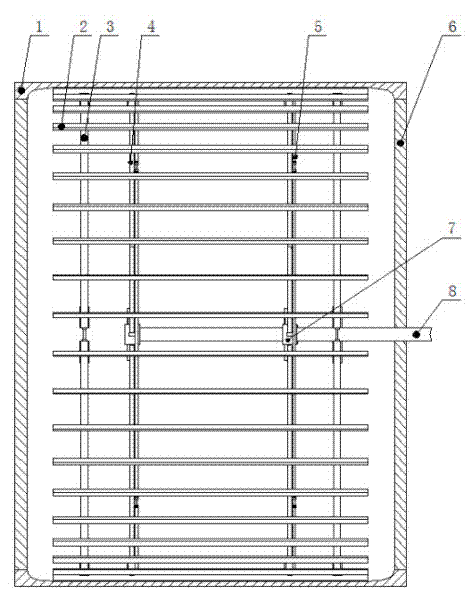

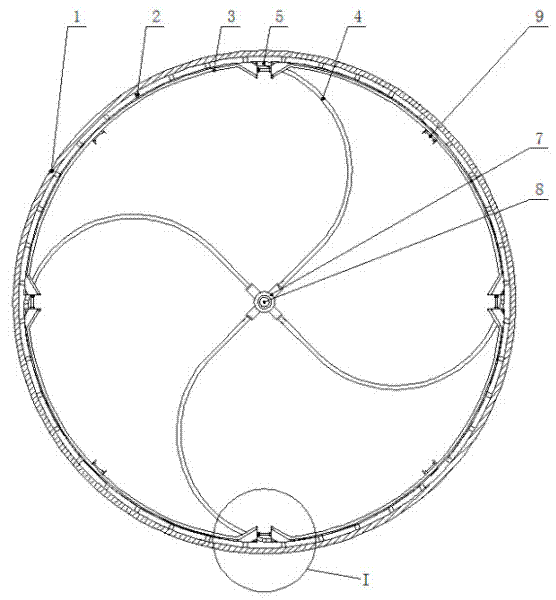

[0037] A high-efficiency energy-saving dryer with a spoiler structure, such as Figure 1~5 As shown, it includes a plurality of connecting rings 3 and a plurality of bar-shaped spoiler rods 2, and the plurality of connecting rings are coaxially arranged in the drying cylinder 1, and the outer edges of the multiple connecting rings are radially evenly distributed and fixed on the inner wall of the drying cylinder The innovation of the present invention is that each spoiler bar is solid and its outer surface is made into an arc that fits closely with the inner wall of the drying cylinder, and the outer surface of each spoiler bar is formed The curved surface of the machine makes the spoiler stick closely to the inner wall of the drying cylinder, and there will be no leakage of condensed water.

[0038] In this embodiment, each spoiler bar is made of high thermal conductivity metals such as aluminum and copper, and the bottom surface of the spoiler bar made of high thermal conduc...

Embodiment 2

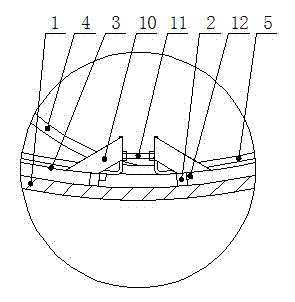

[0046] As shown in Examples 6 to 9 of this embodiment, the structure and size of multiple connecting rings and multiple spoiler rods, as well as the connection relationship between the two and the inner wall of the drying cylinder and the rotating shaft are the same as in Embodiment 1, except that the diameter is greater than 3 meters The structure of the annular water collection siphon device of the drying cylinder is: it includes two water collection rings, four arc-shaped connecting pipes, a five-way head and four connecting pipes. On the inside surface of the bar, each water collection ring is composed of four arc sections connected end to end through locking bolts 9 in turn, and a plurality of siphon ports 12 are evenly distributed on the outer surfaces of the four arc sections, and each siphon port is Spoiler sidewalls in opposite positions (see Figure 9 ), when the drying cylinder rotates, the condensed water accumulates on the side wall of the spoiler bar under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com