Neutral inorganic composite material for dehydration, solidification and modification of high water content sludge

An inorganic composite material and sludge dehydration technology, which is applied in dehydration/drying/thickened sludge treatment, solid waste management, climate sustainability, etc., can solve problems such as alkalinity and secondary pollution, and achieve reduction of stench, High compressive strength, the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

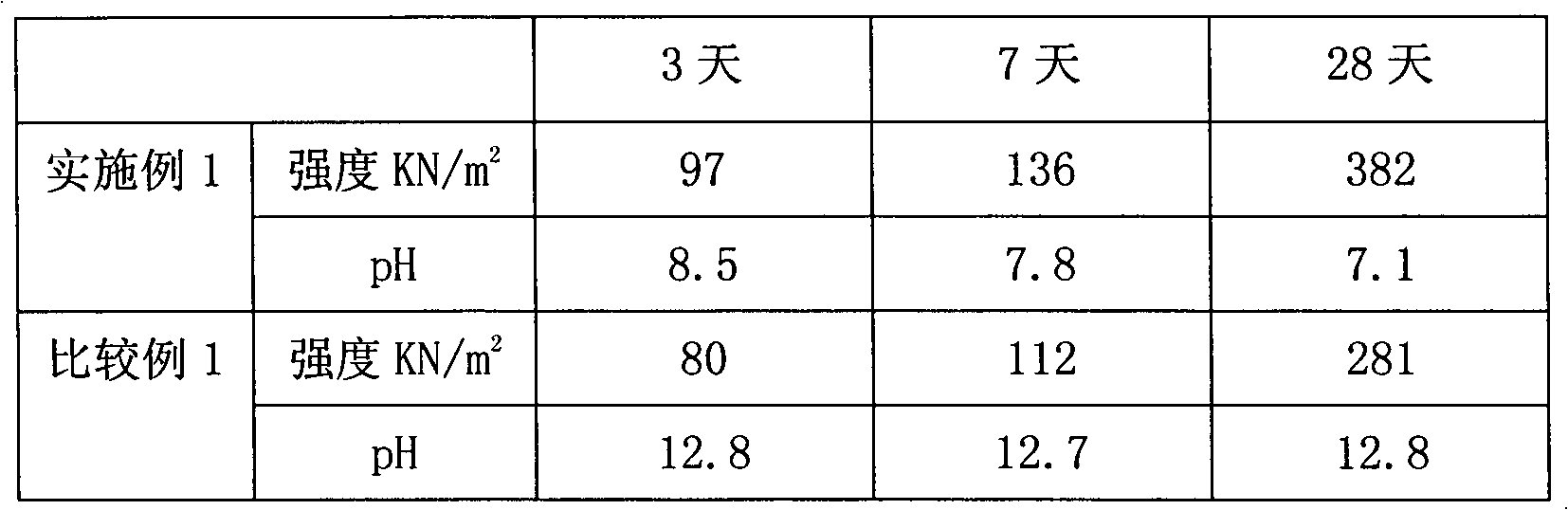

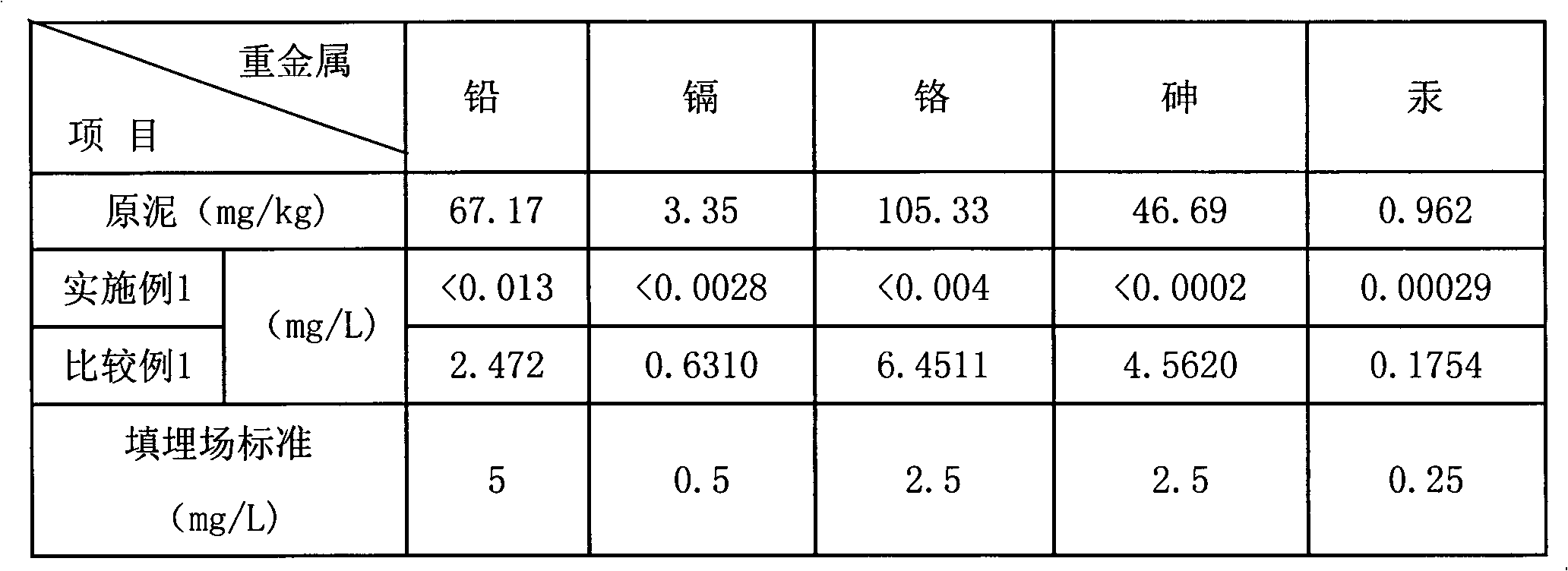

Embodiment 1

[0023] A kind of neutral inorganic composite material which is rapidly dehydrated and solidified and modified by sludge, and takes the following components by weight fraction:

[0024] 100 parts of hydraulic solidification material, which is composed of: 50 parts of hemihydrate gypsum, 50 parts of light magnesium oxide;

[0025] 80 parts of inorganic water-absorbing ash materials, paper mill incineration ash;

[0026] 20 parts of inorganic auxiliary hardening material, silica sand in foundry, particle size is 15-60 μm;

[0027] 2 parts of polymer coagulant, polyacrylamide;

[0028] 1 part of modified functional agent, get 250 parts of potassium chloride, 200 parts of calcium chloride, 22 parts of potassium permanganate, 175 parts of magnesium sulfate, 3 parts of nickel sulfate, 200 parts of sodium sulfate, 13 parts Calcium lignosulfonate and 1 part of citric acid are compounded, and 1 part of modified functional agent after compounding is taken;

[0029] The above-mentioned...

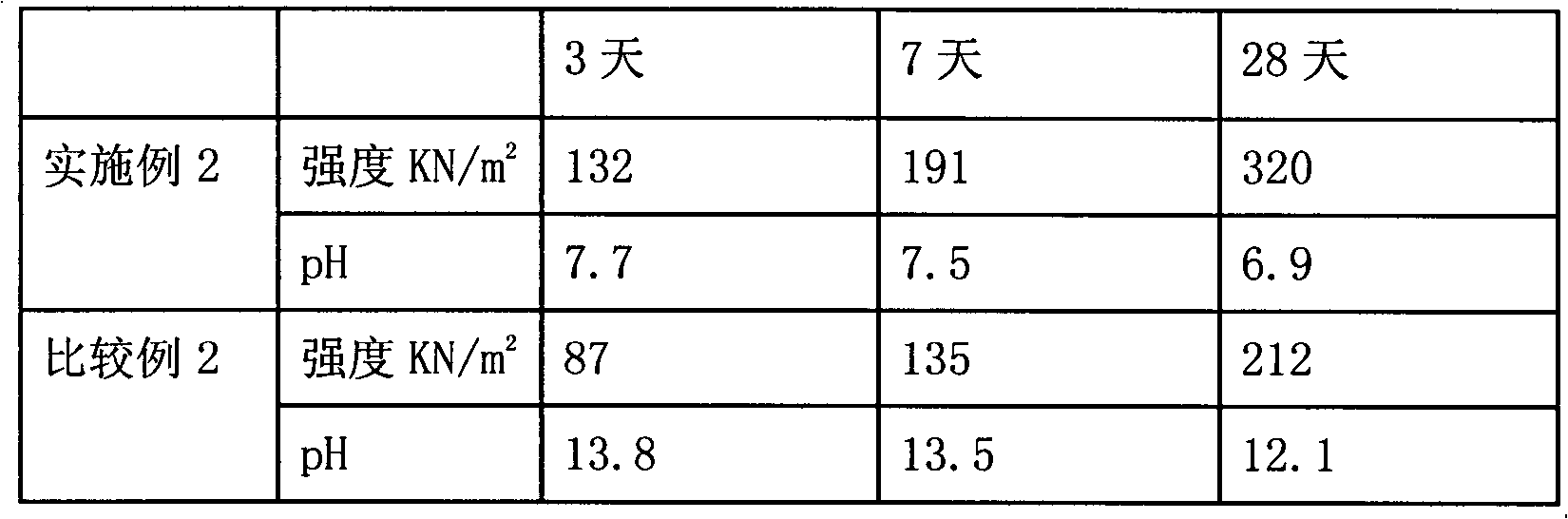

Embodiment 2

[0037] A kind of neutral inorganic composite material which is rapidly dehydrated and solidified and modified by sludge, and takes the following components by weight fraction:

[0038] 100 parts of hydraulic solidification material, which is composed of: 65 parts of hemihydrate gypsum, 35 parts of light magnesium oxide;

[0039] 100 parts of inorganic water-absorbing ash materials, paper mill incineration ash;

[0040] 30 parts of inorganic auxiliary hardening material, silica sand in foundry, particle size 80-120 μm;

[0041] 8 parts of polymer coagulant, sodium polyacrylate;

[0042] 5 parts of modified functional agent, get 200 parts of potassium chloride, 250 parts of calcium chloride, 20 parts of potassium permanganate, 150 parts of magnesium sulfate, 3 parts of nickel sulfate, 225 parts of sodium sulfite, 10 parts of Sodium lignosulfonate and 2 parts of malic acid are compounded, and 5 parts of modified functional agent after compounding are taken;

[0043] The above-...

Embodiment 3

[0051] A kind of rapid dehydration of sludge, solidification modified neutral inorganic composite material, take the following components by weight fraction:

[0052] 100 parts of hydraulic solidification material, which is composed of: 58 parts of hemihydrate gypsum, 42 parts of light magnesium oxide;

[0053] 120 parts of inorganic water-absorbing ash materials, paper mill fly ash;

[0054] 40 parts of inorganic auxiliary hardening material, silicon powder in foundry, particle size 100-150 μm;

[0055] 4 parts of polymer coagulant, sodium carboxymethyl cellulose;

[0056] 3 parts of modified functional agents, which consist of 290 parts of potassium chloride, 230 parts of calcium chloride, 25 parts of potassium permanganate, 200 parts of magnesium sulfate, 2 parts of nickel sulfate, 200 parts of sodium sulfite, 20 parts 3 parts of acryl alcohol polyoxyethylene ether and 3 parts of sodium hexametaphosphate are compounded, and 3 parts of modified functional agent after compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com