Co-processing method for red mud and household garbage incineration fly ash

A domestic waste incineration and co-processing technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of high curing cost of cement or chelating agent, poor long-term stability of solidified body, high energy consumption and high cost of curing, and achieve suitable Large-scale promotion, stable and safe cured body, and low leaching toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for co-processing red mud and domestic waste incineration fly ash, comprising the following steps:

[0028] (1) Preparation of heavy metal curing agent: dry the red mud, grind it through a sieve with a pore size of 0.3mm, mix the sieved red mud with 10% sodium hydroxide, and calcinate at 750°C for 3 hours, after cooling Obtain the heavy metal curing agent. The red mud is taken from a certain place in Henan, and its main chemical composition is 20.38% SiO 2 , 24.50%Al 2 o 3 , 9.48% Fe 2 o 3 , 11.46% Na 2 O, 12.86% CaO, loss on ignition at 1200°C is 15.40%.

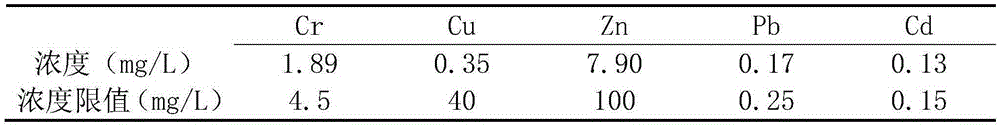

[0029] (2) Prepare clean slurry: mix the heavy metal solidifying agent prepared in step (1) with domestic waste incineration fly ash to obtain a mixture powder, and the mass ratio of the heavy metal solidifying agent in the mixture powder is 45%; According to the water-cement ratio of 0.4, add water and stir evenly to obtain a clean slurry; the fly ash is taken from a waste incineration plant in Hubei...

Embodiment 2

[0034] A method for co-processing red mud and domestic waste incineration fly ash, comprising the following steps:

[0035] (1) Preparation of heavy metal curing agent: dry the solid or semi-solid red mud, grind it through a sieve with an aperture of 0.4mm, mix the sieved red mud evenly with 12.5% sodium hydroxide, and calcinate at 800°C After cooling for 2 hours, the activated pretreated red mud was obtained. The red mud is taken from a certain place in Henan, and its main chemical composition is 20.38% SiO 2 , 24.50%Al 2 o 3 , 9.48% Fe 2 o 3 , 11.46% Na 2 O, 12.86% CaO, loss on ignition at 1200°C is 15.40%.

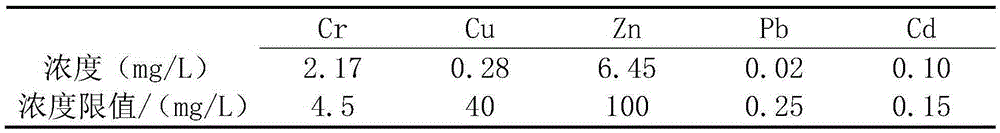

[0036] (2) Prepare clean slurry: mix the heavy metal solidifying agent prepared in step (1) with domestic waste incineration fly ash to obtain a mixture powder, and the mass ratio of the heavy metal solidifying agent in the mixture powder is 50%; According to the water-cement ratio of 0.5, add water and stir evenly to obtain a clean slurry; the fly ash is taken...

Embodiment 3

[0041] A method for co-processing red mud and domestic waste incineration fly ash, comprising the following steps:

[0042] (1) Preparation of heavy metal curing agent: dry the solid or semi-solid red mud, grind it through a sieve with an aperture of 0.5mm, mix the sieved red mud with 15% sodium hydroxide, and calcinate at 850°C After cooling for 1 hour, the activated pretreated red mud was obtained. The red mud is taken from a certain place in Henan, and its main chemical composition is 20.38% SiO 2 , 24.50%Al 2 o 3 , 9.48% Fe 2 o 3 , 11.46% Na 2 O, 12.86% CaO, loss on ignition at 1200°C is 15.40%.

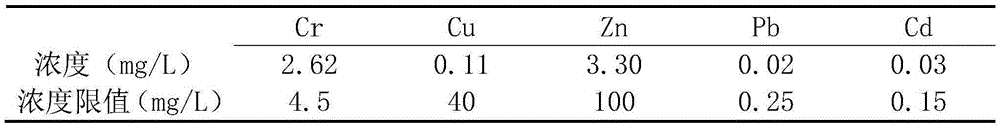

[0043] (2) Prepare clean slurry: mix the heavy metal solidifying agent prepared in step (1) with domestic waste incineration fly ash to obtain a mixture powder, and the mass ratio of the heavy metal solidifying agent in the mixture powder is 60%; According to the water-cement ratio of 0.6, add water and stir evenly to obtain a clean slurry; the fly ash is taken from a wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com