Sodium sulfanilate modified polycarboxylate superplasticizer and preparing method of sodium sulfanilate modified polycarboxylate superplasticizer

A technology of sodium sulfanilate and polycarboxylic acid is applied in the field of material synthesis to achieve the effects of improving dispersibility, good mechanical properties and short reaction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

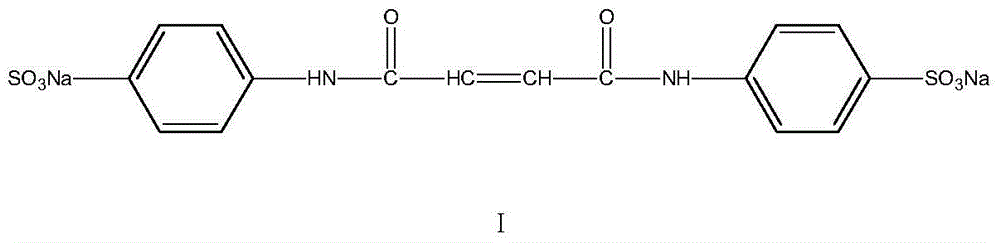

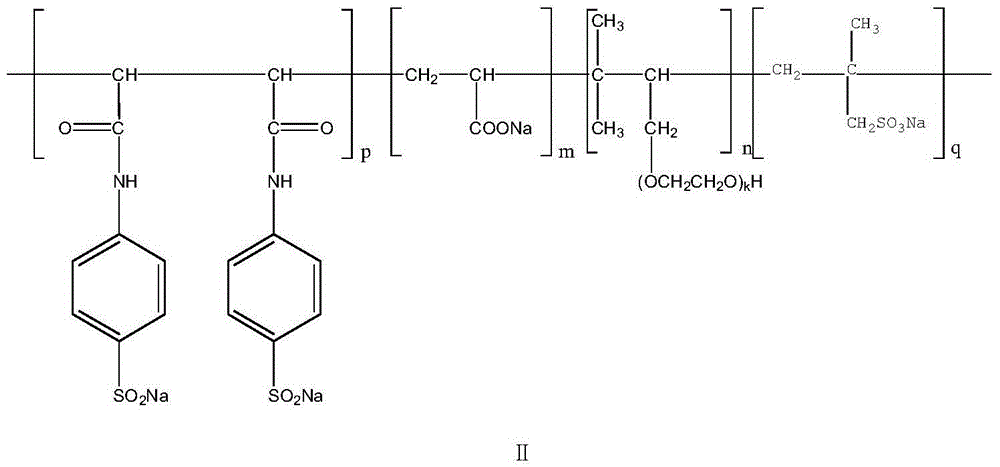

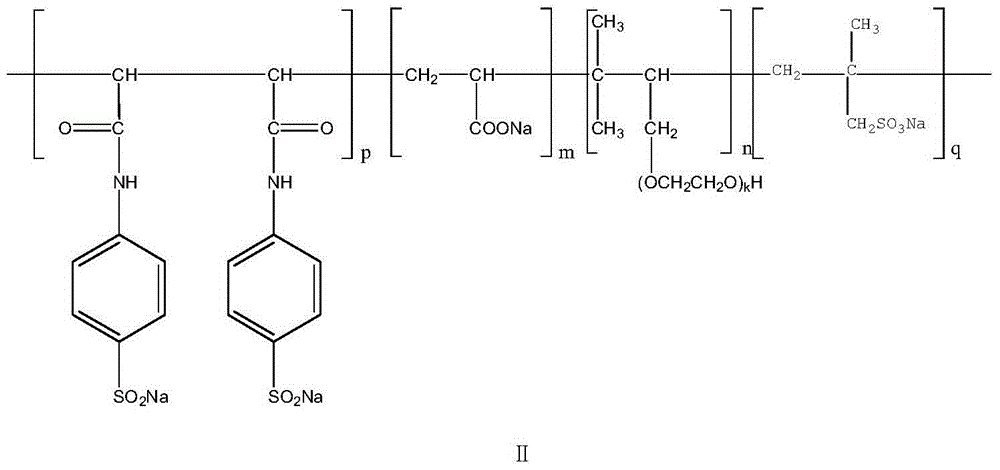

[0023] Taking the total weight of each raw material as a basis, take the raw materials according to the mass percentage of each raw material, stir the 9.74wt% sodium p-sulfanilate, 5.52wt% maleic anhydride and 9.74wt% toluene evenly, then stir and heat up to React at 60±1°C for 3 hours. After the reaction is over, distill off the solvent toluene, cool to room temperature, add water, and stir evenly to obtain the corresponding intermediate product. The aqueous solution of the compound of formula I is preferably formulated to a mass percentage of 40 wt. The aqueous solution of the intermediate product formula I compound of %;

[0024] Then, add 68wt% prenol-terminated polyoxyethylene ether, 4.0wt% acrylic acid and add 2.0wt% sodium methacrylic acid sulfonate, stir and dissolve, and prepare a 40% homogeneous solution; then add 0.4 Mix wt% oxidant ammonium persulfate and potassium permanganate, stir for 5min, add 0.6wt% reducing agent sodium formaldehyde sulfoxylate and L-ascorbic...

Embodiment 2

[0028] Take the total weight of each raw material as a basis, take the raw materials according to the mass percentage of each raw material, stir the 3.90wt% sodium p-sulfanilate, 2.20wt% maleic anhydride and 3.90wt% toluene, then stir and heat up to React at 55±1°C for 4 hours. After the reaction is over, distill off the solvent toluene, cool to room temperature, add water, and stir evenly to obtain the corresponding intermediate product. The aqueous solution of the compound of formula Ⅰ is preferably formulated to a mass percentage of 40 wt. The aqueous solution of the intermediate product formula I compound of %;

[0029] Then, add 83wt% prenol-terminated polyoxyethylene ether, 4.0wt% acrylic acid and 2.0wt% sodium methacrylic acid sulfonate, stir and dissolve, and prepare a 40% homogeneous solution; then add 0.6 Mix wt% oxidant ammonium persulfate and potassium permanganate, and the molar ratio of ammonium persulfate and potassium permanganate is 4:1, stir for 5min, then ad...

Embodiment 3

[0033]Take the total weight of each raw material as a basis, take the raw materials according to the mass percentage of each raw material, stir the maleic anhydride and 8.18wt% toluene of 8.18wt% sodium p-aminobenzenesulfonate, 4.64wt% toluene, then stir and heat up to React at 65±1°C for 3.0 hours. After the reaction is over, distill off the solvent toluene, cool to room temperature, add water, and stir evenly to obtain the corresponding intermediate product. The aqueous solution of the compound of formula I, preferably formulated to a mass percentage of 40wt The aqueous solution of the intermediate product formula I compound of %;

[0034] Then, add 73wt% prenol-terminated polyoxyethylene ether, 3.0wt% acrylic acid and 2.0wt% sodium methacrylic acid sulfonate, stir and dissolve, and prepare a 40% homogeneous solution; then add 0.5 Mix wt% oxidant ammonium persulfate and potassium permanganate, and the molar ratio of ammonium persulfate and potassium permanganate is 6:1, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com