Addition compound suitably used as wetting dispersant and preparation method thereof

A technology of addition compounds, wetting and dispersing agents, used in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., can solve the problems of high viscosity and thixotropy, low viscosity, poor fluidity, etc. The effect of enhanced ability, excellent comprehensive dispersion performance, and enhanced steric hindrance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

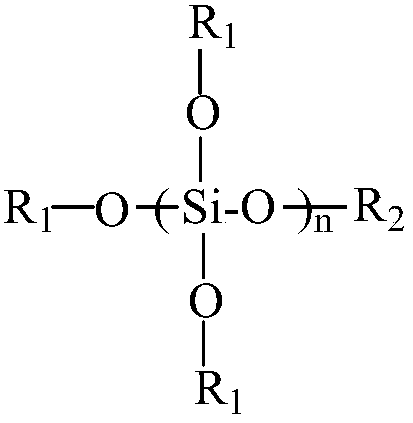

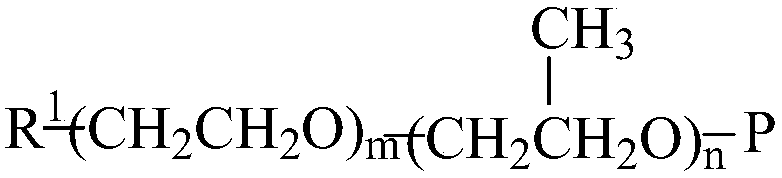

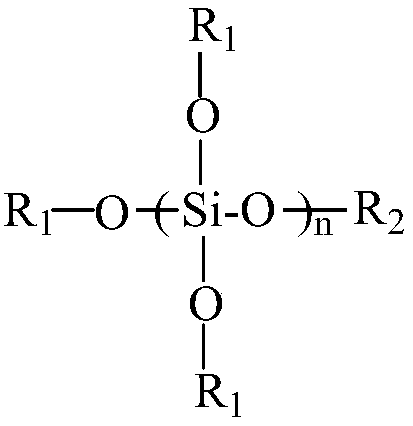

[0037] Synthesis of branched polyether-ethyl silicate

[0038] Polyether-ethyl silicate branched product 1

[0039] Under nitrogen protection, 208.33 parts of tetraethyl orthosilicate 28, 2325 parts of polyethylene glycol monomethyl ether (Mn = 750) were added at room temperature In the four-neck flask of the condenser tube of the device, and make it homogenized. Turn on the heating device, set the reaction temperature to 120°C, start stirring at the same time, set the stirring speed to 200rpm, when the reaction mixture reaches about 120°C, the reaction starts, and the transesterification reaction product ethanol is fractionated from the fractionator, collect the fractions, and maintain the temperature for the reaction 1h, then heated the mixture to 160°C, kept at this temperature to collect fractions, maintained the temperature for 1h, finally heated the mixture to 190°C, kept at this temperature to collect fractions, maintained the temperature for 1h, then terminated the re...

Embodiment 2

[0058] Example 2: Dispersions of particulate solids and their thixotropic properties

[0059] With dispersing aid 1,5,8 (solid content 50%) of the present invention shown in following table 2 or commercially available dispersing aid BYK110 (solid content 50%) respectively with short oil degree alkyd resin (solid content 60%), titanium dioxide in powder form, propylene glycol methyl ether acetate were mixed and dispersed with glass beads in a Dispermat disperser for 1 hour to obtain dispersions 1, 2, 3 and control dispersions of granular solids.

[0060] Table 2

[0061]

[0062]

[0063] Note: The viscosity of the dispersion of particulate solids was measured using a Brookfield LVDV-I Prime viscometer using spindle #3.

[0064] The above results show that the solid dispersion of inorganic pigment particles containing the dispersant of the present invention exhibits lower viscosity and thixotropy, and exhibits more excellent dispersibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com