Complex dispersant water-based liquid magnetic grinding tool and manufacturing method thereof

A composite dispersant and water-based liquid technology, which is applied in grinding/polishing equipment, grinding devices, manufacturing tools, etc., can solve the problems of poor redispersibility and poor stability, and achieve low cost, strong oxidation resistance, and settlement good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0045] Embodiment used raw material is as follows:

[0046] Deionized water is 20.4%, carbonyl iron powder is 67%, surfactant is 1.3%, nano silicon dioxide is 0.5%, conditioner and antioxidant is 0.8%, humectant is 0.3%, green silicon carbide particles are 9.7% %. The surfactants in the formula are sodium hexametaphosphate and sodium carboxymethylcellulose, and the mass ratio is 40:3.

[0047] The preparation steps are as follows:

[0048] 1) According to the formula described in the invention, weigh 70ml of deionized water, 0.3g sodium carboxymethylcellulose, 4g sodium hexametaphosphate, 2gNaNO 2 And 1ml glycerol and 1.5g anhydrous sodium carbonate;

[0049] 2) Put deionized water in a container tank, then add sodium hexametaphosphate and sodium carboxymethylcellulose, stir with a stirrer, adjust the speed to 300r / min, and stir to disperse them evenly in deionized water ;

[0050]3) Add sodium nitrite and anhydrous sodium carbonate to the mixed solution, mix in the conta...

Embodiment approach 2

[0058] Embodiment used raw material is as follows:

[0059] Deionized water is 20.4%, carbonyl iron powder is 67%, surfactant is 1.3%, nano silicon dioxide is 0.5%, conditioner and antioxidant is 0.8%, humectant is 0.3%, green silicon carbide particles are 9.7% %. The surfactants in the formula are sodium hexametaphosphate and PAA, and the mass ratio is 5:2.

[0060] The preparation steps are as follows:

[0061] 1) According to the formula described in the invention, weigh 70ml of deionized water, 1.25g of PAA, 3g of sodium hexametaphosphate, 2g of NaNO according to the mass fraction 2 and 1ml glycerol and 2g anhydrous sodium carbonate;

[0062] 2) Put the deionized water in a container tank, then add sodium hexametaphosphate and PAA, stir with a stirrer, adjust the speed to 300r / min, and stir to disperse it evenly into the deionized water;

[0063] 3) Add sodium nitrite and a small amount of anhydrous sodium carbonate to the mixed solution, mix in the container, adjust t...

Embodiment approach 3

[0071] Embodiment used raw material is as follows:

[0072] Deionized water is 20.4%, carbonyl iron powder is 67%, surfactant is 1.1%, nano silicon dioxide is 0.7%, conditioner and antioxidant is 0.8%, humectant is 0.3%, green silicon carbide particles are 9.7% %. The surfactant in the formula is sodium carboxymethylcellulose and PAA, and the mass ratio is 1:10.

[0073] The preparation steps are as follows:

[0074] (1) According to the formula described in the invention, weigh 70ml of deionized water, 3.5g of PAA, 0.35g of sodium carboxymethyl cellulose, and 2g of NaNO according to the mass fraction 2 and 1ml of glycerin and 2g of anhydrous sodium carbonate.

[0075] (2) Put the deionized water in a container tank, then add sodium carboxymethylcellulose and PAA, stir with a stirrer, adjust the speed to 300r / min, and stir to disperse them evenly in the deionized water.

[0076] (3) Add sodium nitrite and anhydrous sodium carbonate to the mixed solution, mix in a container...

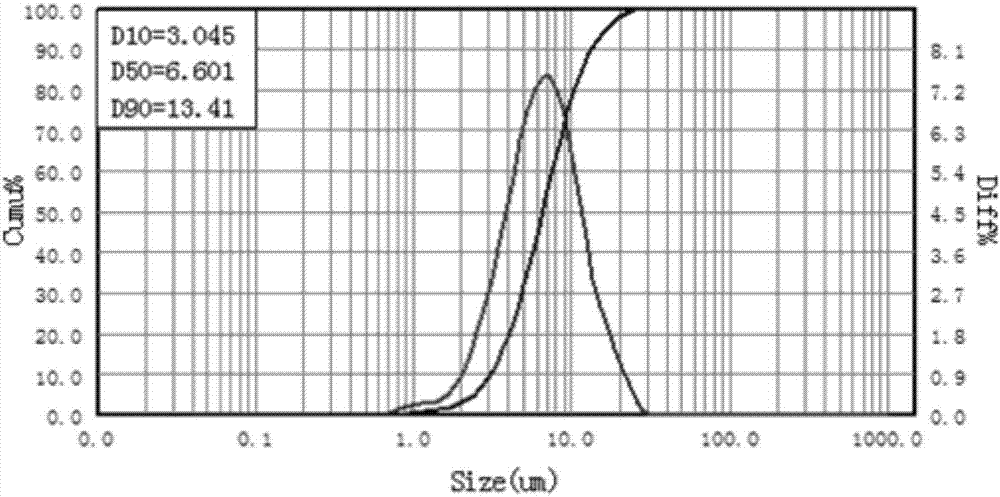

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com