Preparation method for anti-mud polycarboxylate water reducing agent used for polyether with molecular weight of 3,000

A technology of molecular weight and water reducing agent, applied in the field of concrete admixtures and building materials, can solve the problems of difficulty in breaking free, lose the dispersion effect, restrain the molecules of the water reducing agent, etc., and achieve the effect of enhancing steric hindrance and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

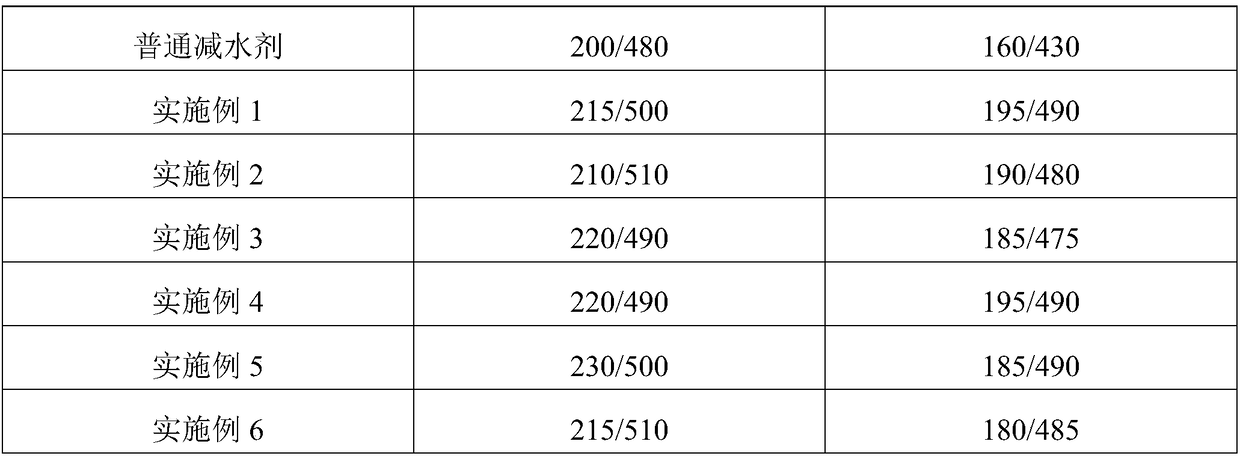

Examples

Embodiment 1

[0033] A mud-resistant polycarboxylate superplasticizer for 3000 molecular weight polyether, mainly prepared from the following components: 3000 molecular weight polyether macromonomer, hydrogen peroxide, acrylic acid, unsaturated sulfonate, ascorbic acid, phenylcarboxylic acid Functional monomer, phosphate ester functional monomer, chain transfer agent, neutralizer and water; the total mass is 1000 parts, and the mass fraction of finished product after preparation is 40%. The preparation method includes the following steps:

[0034] 1) Add 335 parts of Oak 702, 5 parts of methacryloxyethyl phthalate monoester, 5.5 parts of ethylene glycol methacrylate phosphate and 220 parts of water into the reaction kettle, stir and heat until the dissolve;

[0035] 2) Measure the temperature in the kettle, control the temperature at 46°C, and after the temperature is stable, add 0.8 parts of 27.5% industrial grade hydrogen peroxide at one time;

[0036] 3) After 5 minutes, start to add so...

Embodiment 2

[0039] A mud-resistant polycarboxylate superplasticizer for 3000 molecular weight polyether, mainly prepared from the following components: 3000 molecular weight polyether macromonomer, hydrogen peroxide, acrylic acid, unsaturated sulfonate, ascorbic acid, phenylcarboxylic acid Functional monomer, phosphate ester functional monomer, chain transfer agent, neutralizer and water; the total mass is 1000 parts, and the mass fraction of finished product after preparation is 40%. The preparation method includes the following steps:

[0040] 1) Add 342 parts of Oak 703, 2 parts of hydroxyethyl pyrphthalic anhydride dimethacrylate, 5.3 parts of methacryloyloxyethyl phosphate and 210 parts of water into the reactor, stir and heat until it dissolves;

[0041] 2) Measure the temperature in the kettle, control the temperature at 47°C, and after the temperature is stable, add 0.9 parts of 27.5% industrial grade hydrogen peroxide at one time;

[0042] 3) After 5 minutes, start to add solutio...

Embodiment 3

[0045] A mud-resistant polycarboxylate superplasticizer for 3000 molecular weight polyether, mainly prepared from the following components: 3000 molecular weight polyether macromonomer, hydrogen peroxide, acrylic acid, unsaturated sulfonate, ascorbic acid, phenylcarboxylic acid Functional monomer, phosphate ester functional monomer, chain transfer agent, neutralizer and water; the total mass is 1000 parts, and the mass fraction of finished product after preparation is 40%. The preparation method includes the following steps:

[0046] 1) Composition of 340 parts of Levima WR6251, 6 parts of methacryloyloxyethyl trimellitic anhydride, 4 parts of methacryloyloxyethyl phosphate and ethylene glycol methacrylate phosphate in a mass ratio of 2:1 200 parts of water are added into the reaction kettle, stirred and heated until it dissolves;

[0047] 2) Measure the temperature in the kettle, control the temperature at 48°C, and after the temperature stabilizes, add 1 part of industrial g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com