Zero-VOC (volatile organic compound) cement-based water-proof material copolymer emulsion and preparation method thereof

A waterproof material and polymer emulsion technology, which is applied in the field of waterproof coatings, can solve the problems of weak anti-ultraviolet ability, unfavorable industrial production, and high cost of styrene-butadiene latex, and achieve excellent rheological properties, good emulsification effect, and low water absorption of the coating film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

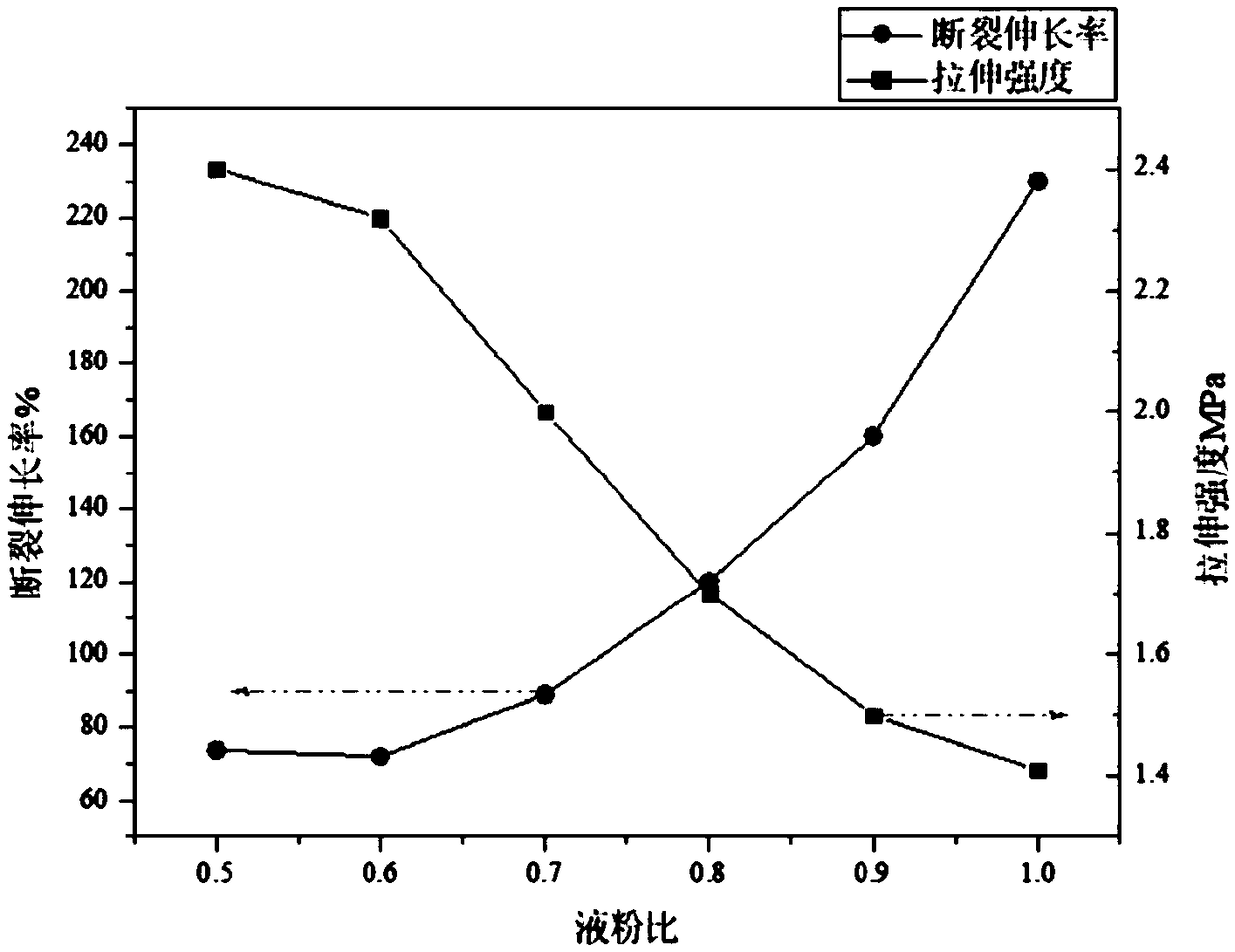

[0055] (1) Preparation of component A zero VOC polymer emulsion:

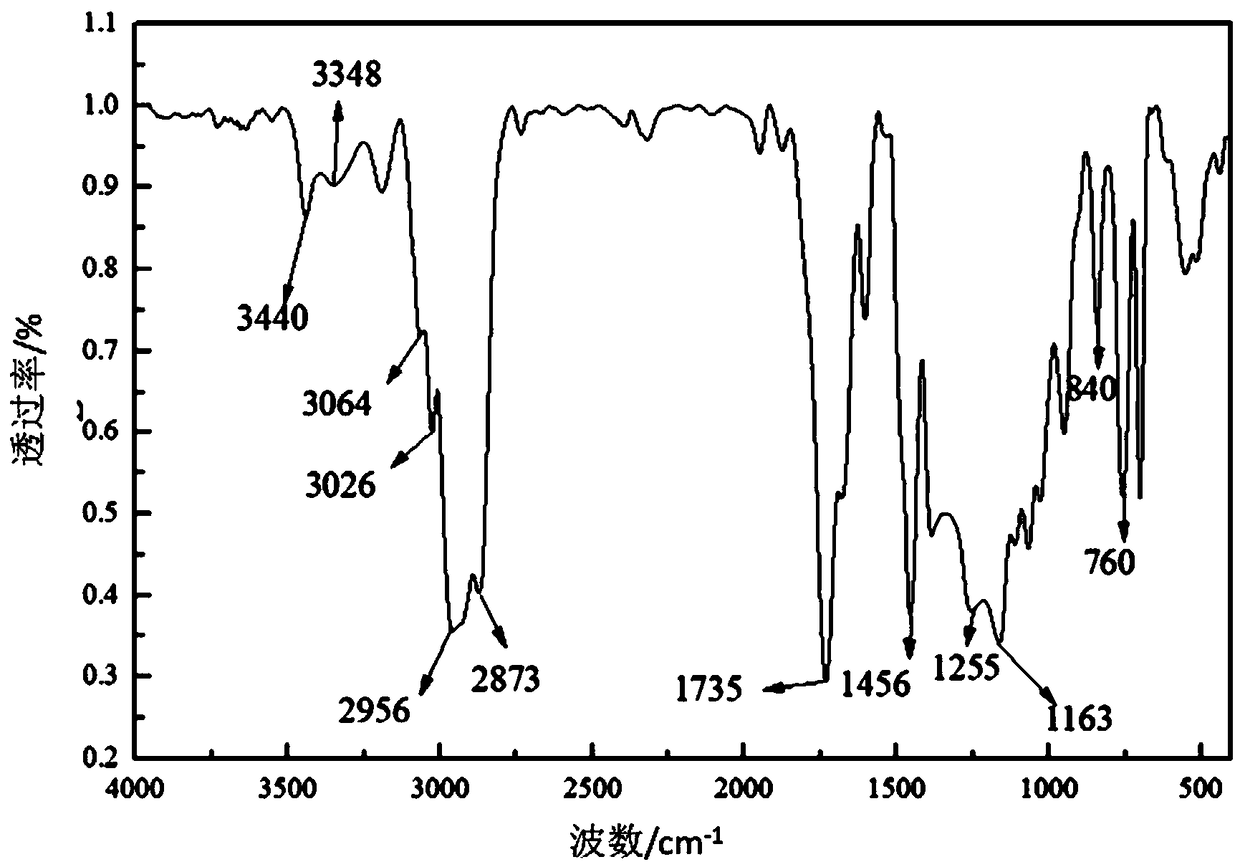

[0056] 1.1 Preparation of pre-emulsion: add 30 parts of deionized water, 0.5 parts of BASFSLS103 anionic emulsifier, 0.5 parts of German Ham TX-10 non-ionic emulsifier to the emulsification tank in terms of mass fraction, and then use a peristaltic pump to add 30 parts Methyl acrylate, 30 parts of n-butyl acrylate, 10 parts of styrene, 0.1 part of acrylic acid and 0.1 part of methacrylic functional monomer are added to the emulsification tank, and the stirring blade is turned on for high-speed shear emulsification. The speed of the stirring blade is 300rpm, and the stirring The time is 20min.

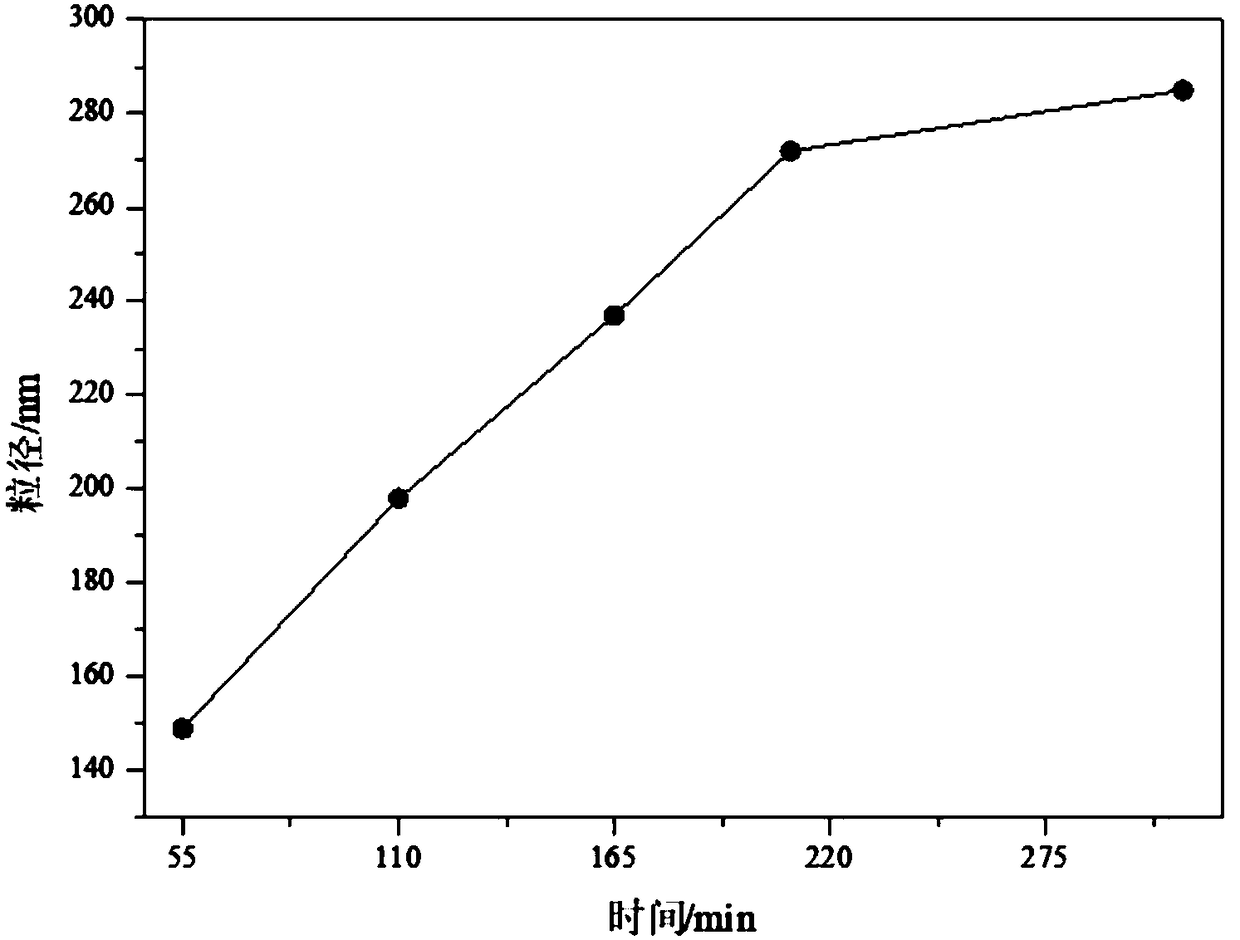

[0057] 1.2 Emulsion polymerization: In terms of mass fraction, add 60 parts of deionized water, 0.5 parts of BASF SLS103 anionic emulsifier, and 0.5 parts of German Ham TX-10 non-reactor into a reactor equipped with a stirring blade, condenser and peristaltic pump feeding device. Ionic emulsifier, 0.1 part of sodium carbonat...

Embodiment 2

[0062] (1) Preparation of component A zero VOC polymer emulsion:

[0063] 1.1 Preparation of pre-emulsion: add 33 parts of deionized water, 0.7 parts of Dow DOWFAX 2A1 anionic emulsifier, 0.3 parts of BASF EUMULGIN CO 40 non-ionic emulsifier to the emulsification tank, and then use a peristaltic pump to add 60 parts of n-butyl acrylate , 20 parts of styrene and 0.5 parts of acrylamide functional monomer are added to the emulsification tank, and at the same time the stirring blade is turned on for high-speed shear emulsification, the speed of the stirring blade is 350rpm, and the stirring time is 25min.

[0064] 1.2 Emulsion polymerization: Add 63 parts of deionized water, 1.0 part of Dow DOWFAX 2A1 anionic emulsifier, 0.7 part of BASF EUMULGIN CO 40 non-ionic emulsifier, and 0.2 Parts of sodium bicarbonate buffer, 0.02 parts of tetrachlorobenzoquinone polymerization inhibitor, the temperature in the kettle is raised to 89-91℃, quickly add 6% of the pre-emulsion solution and 0.4 par...

Embodiment 3

[0069] (1) Preparation of component A zero VOC polymer emulsion:

[0070] 1.1 Preparation of pre-emulsion: add 35 parts of deionized water, 0.6 parts of German Ham NP-10 anionic emulsifier, 0.5 parts of BASF A25 non-ionic emulsifier to the emulsification tank in terms of mass fraction, and then use a peristaltic pump to remove 30 Part of n-butyl acrylate, 45 parts of ethyl acrylate, 30 parts of styrene, 0.5 part of hydroxyethyl methacrylate and 0.6 part of methacrylic functional monomer are added to the emulsification tank, and the stirring blade is turned on for high-speed shear emulsification and stirring The paddle speed is 400 rpm, and the stirring time is 30 min.

[0071] 1.2 Emulsion polymerization: In terms of mass fraction, add 65 parts of deionized water, 0.8 parts of German Ham NP-10 anionic emulsifier, and 0.4 parts of BASF A25 into a reactor equipped with a stirring blade, condenser and peristaltic pump feeding device. Ionic emulsifier, 0.3 part of sodium carbonate buf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com