Photocatalyst solution for formaldehyde degradation under visible light, and preparation method thereof

A technology of photocatalyst and visible light, applied in separation methods, chemical instruments and methods, fibrous fillers, etc., can solve the problems of low utilization rate of sunlight and achieve the effect of improving steric hindrance and reducing sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

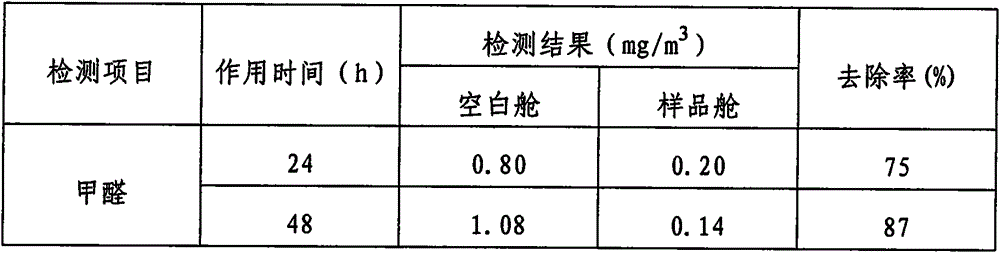

Embodiment 1

[0024] 1. In parts by mass, reflux 0.25 parts of nano-titanium oxynitride, 1 part of silane coupling agent KH550 and 1 part of anionic surfactant sodium dodecylbenzenesulfonate in an organic solvent petroleum ether in a water bath (60°C) for 6 hours, and then distilled and dried to obtain modified nano-titanium oxynitride powder.

[0025] 2. Add 3 parts of anchor chain polymer dispersant and 94.75 parts of deionized water to the modified nano-titanium oxynitride powder prepared in the first step, and disperse the above mixture through a high-pressure shear dispersion device (2000 revolutions per minute) , vacuum filtration, and buffer storage to obtain the photocatalyst solution.

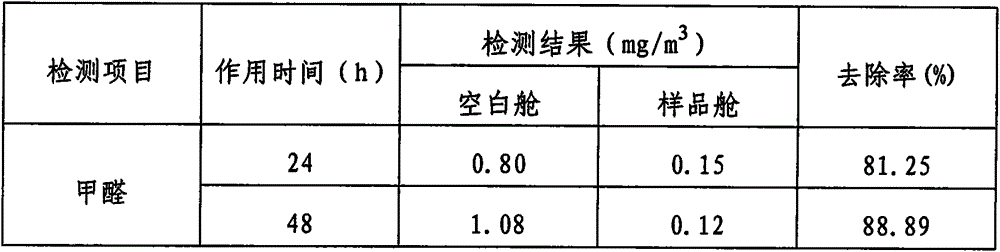

Embodiment 2

[0027] 1. In parts by mass, put 1 part of nano-titanium oxynitride and 3 parts of silane coupling agent KH570 and 3 parts of cationic surfactant hexadecyltrimethylammonium bromide in an organic solvent petroleum ether in a water bath (60°C ) was refluxed for 6 hours, and then dried by distillation to obtain a modified nano-titanium oxynitride powder.

[0028] 2. Add 3 parts of anchor chain polymer dispersant and 90 parts of deionized water to the modified nano-titanium oxynitride powder prepared in the first step, and disperse the above mixture through a high-pressure shear dispersion device (2000 revolutions per minute) , vacuum filtration, and buffer storage to obtain the photocatalyst solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com