High-solid-phase-content aluminum oxide photosensitive ceramic material and preparation method thereof

A technology of alumina ceramics and photosensitive ceramics, applied in the field of 3D printing, can solve the problems of increasing energy consumption, difficult to promote the process, unable to meet different needs and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

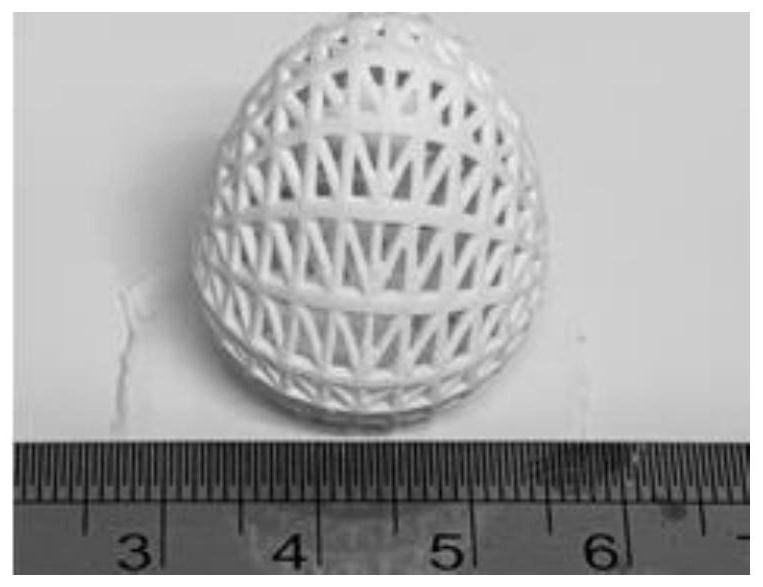

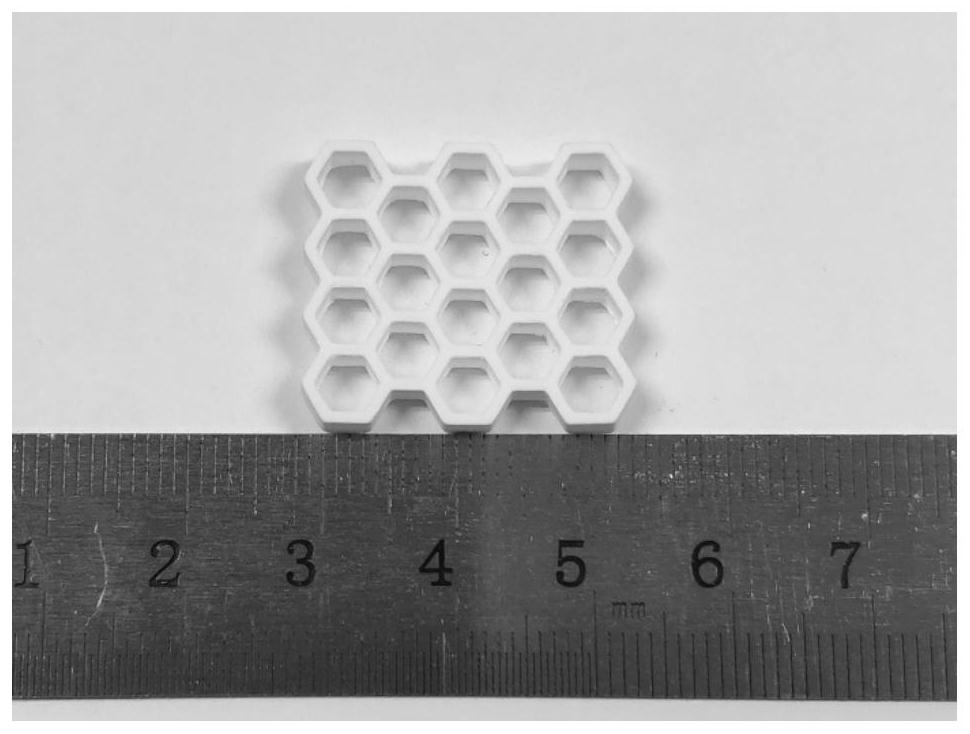

Examples

preparation example Construction

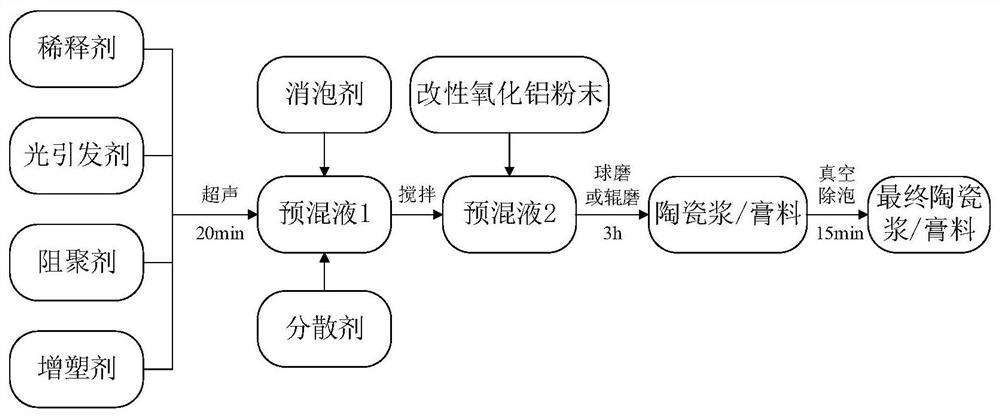

[0039]The invention discloses a method for preparing a photosensitive alumina photosensitive ceramic material with a high solid phase content. In order to increase the solid content and reduce the viscosity and solve the problem of uniform dispersion of the powder in the ceramic photosensitive material, the ceramic powder is pretreated and the powder is mixed with the photosensitive pretreatment method. Adding a specific dispersant when the mixed liquid is mixed; and adjusting the mass ratio of the surfactant and dispersant used in the pretreatment to obtain ceramic photosensitive materials in different states with the same solid content, including the following steps:

[0040] S1: Disperse the alumina ceramic powder into surfactant dilution for modification treatment, obtain the modified ceramic powder after drying and ball milling;

[0041] Include in described step S1:

[0042] First, mix the surfactant (unsaturated organic acid stearic acid, carboxylic acid, oleic acid, et...

Embodiment 1

[0055] (1) Modification of alumina ceramic powder: take 80g alumina powder (particle size 0.2~3μm, purity 99.9%), 0.8g oleic acid, and 160g absolute ethanol; first add oleic acid and absolute ethanol to the Erlenmeyer flask Neutralize and stir evenly, then add the alumina powder into the surfactant diluent, and react with magnetic stirring at 70°C for 30 minutes; after the end, wash the modified powder and dry it at 80°C; finally, ball mill the powder for 1 to 2 hours at a speed of 200r / min to obtain modified alumina powder.

[0056] (2) Preparation of photosensitive premix: take 2.9g of isooctyl acrylate, 8.7g of ethoxylated trimethylolpropane triacrylate, 3.3g of trimethylolpropane triacrylate, 1,6-hexanediol Diacrylate 0.16g, 2,2,4-trimethylpentanediol isobutyl ester 4.4g, photoinitiator (184) 0.26g; 1.6g dispersant (polyester amide) and polymerization inhibitor were added in proportion In a beaker, ultrasonically disperse at 25°C for 20 minutes to prepare a photosensitive...

Embodiment 2

[0059] (1) Modification of alumina ceramic powder: take 800g alumina powder (particle size 0.2~3μm, purity 99.9%), 32g oleic acid, 1600g dehydrated ethanol respectively; add oleic acid and dehydrated ethanol in the Erlenmeyer flask first and stir evenly, then add the alumina powder into the diluent of the surfactant, and react with magnetic stirring at 70°C for 30 minutes; after the end, wash the modified powder and dry it at 80°C; finally, ball mill the powder for 1-2 hours at a speed of 200r / min to obtain modified alumina powder.

[0060] (2) Preparation of photosensitive premix: Take 29.6g of isooctyl acrylate, 86.7g of ethoxylated trimethylolpropane triacrylate, 32.92g of trimethylolpropane triacrylate, 1,6-hexanediol Diacrylate 1.64g, 2,2,4-trimethylpentanediol isobutyl ester 43.9g, benzoin dimethyl ether 2.6g (photoinitiator 651); 16g dispersant (polyester amide) and proportional The polymerization inhibitor was added into the beaker, and ultrasonically dispersed at 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com