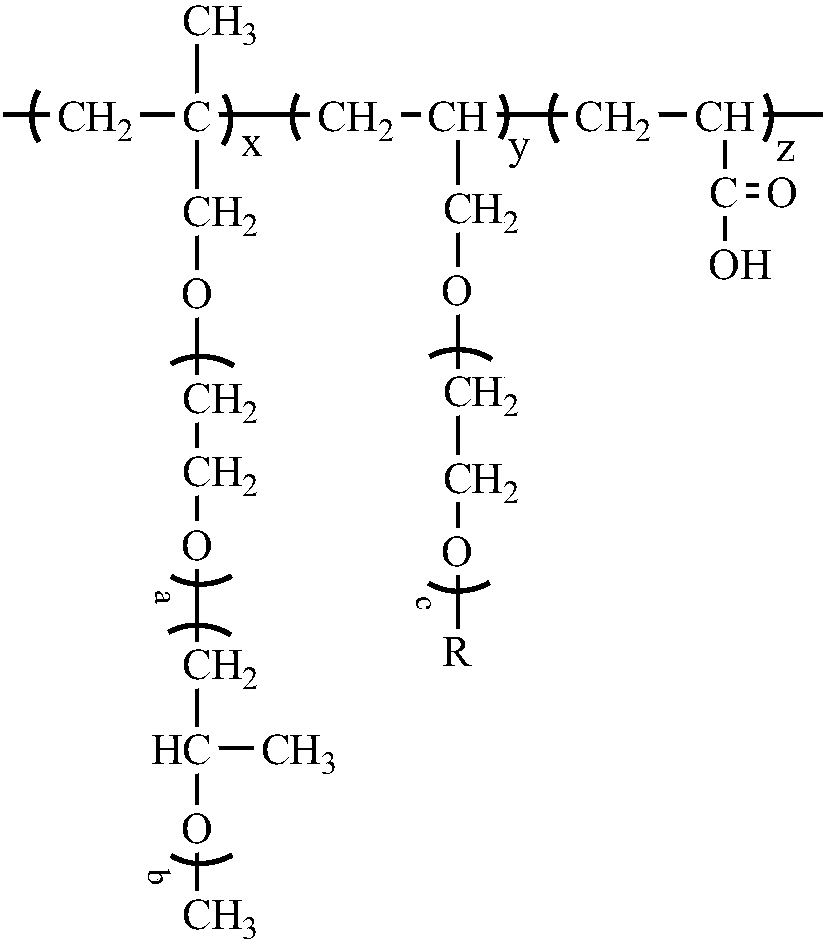

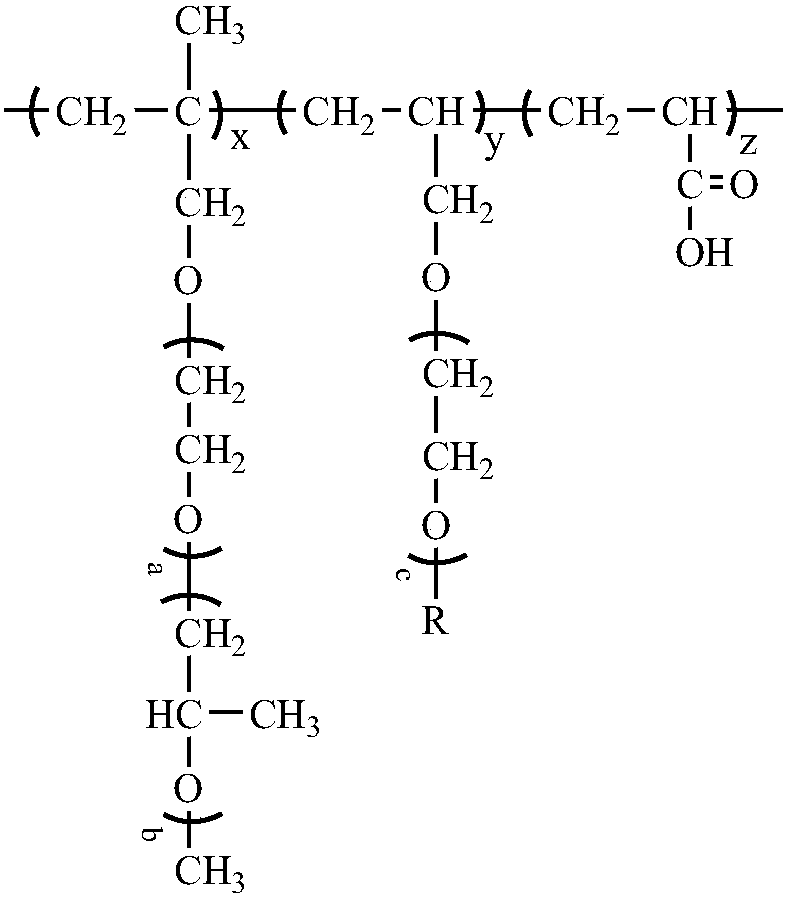

Hydrophobically modified viscosity-reducing polycarboxylate superplasticizer and preparation method thereof

A technology of hydrophobic modification and polycarboxylate, which is applied in the field of polycarboxylate water reducer, can solve the problems of reducing polycarboxylate adsorption, dispersion, unfavorable concrete strength growth, unfavorable polymerization reaction conversion rate, etc., to achieve favorable Concrete strength, beneficial to the discharge of air bubbles, and the effect of reducing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

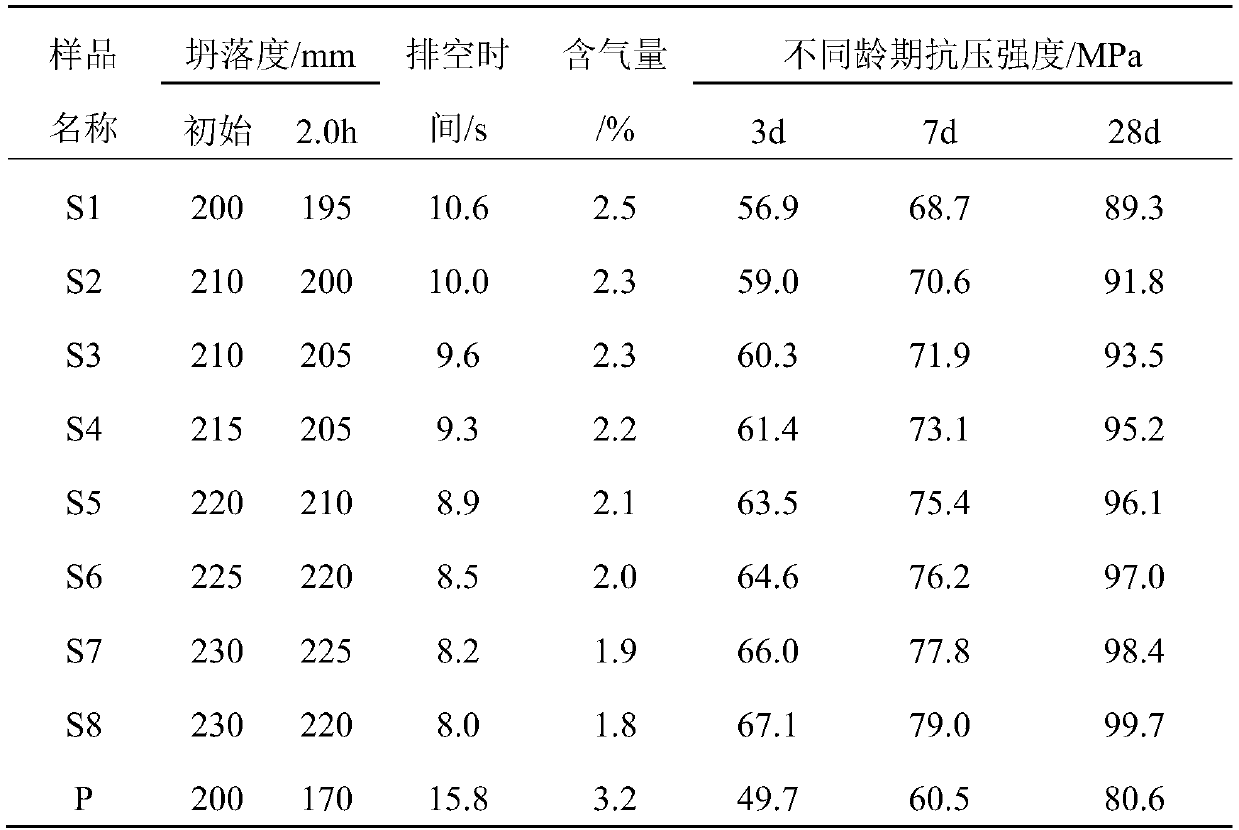

Examples

Embodiment 1

[0031] (1) Preparation of hydrophobically modified allyl polyethylene glycol: under nitrogen protection, add 1.0 mol of allyl polyethylene glycol with a molecular weight of 718 into the reaction kettle, stir and heat up to 70°C, add sodium hydroxide As a catalyst, slowly add 1.0mol of 1-bromopropane after reacting for 15min, react at 70°C for 3.0h, add 2.0mol of deionized water, and adjust the pH to 4.8-5.2 with glacial acetic acid, continue to react for 0.5h, and the reaction is complete Dry to obtain white solid hydrophobically modified allyl polyethylene glycol;

[0032] (2) Preparation of hydrophobically modified viscosity-reducing polycarboxylate superplasticizer: methallyl polyoxyethylene polyoxypropylene ether with a molecular weight of 1902, hydrophobically modified allyl polyethylene glycol, and acrylic acid Add acrylic acid and deionized water with a total molar weight of 10% to the reaction kettle, stir and dissolve at 10°C to obtain a solution; Water mixed solutio...

Embodiment 2

[0034] (1) Preparation of hydrophobically modified allyl polyethylene glycol: under the protection of nitrogen, add 1.0 mol of allyl polyethylene glycol with a molecular weight of 806 into the reaction kettle, stir and heat up to 70°C, add sodium hydroxide As a catalyst, slowly add 1.0mol of 1-bromobutane after reacting for 20min, react at 70°C for 3.0h, add 2.3mol of deionized water, and adjust the pH to 4.8-5.2 with glacial acetic acid, continue to react for 0.5h, react After drying, a white solid hydrophobically modified allyl polyethylene glycol is obtained;

[0035] (2) Preparation of hydrophobically modified viscosity-reducing polycarboxylate water reducer: methallyl polyoxyethylene polyoxypropylene ether with a molecular weight of 1958, hydrophobically modified allyl polyethylene glycol, and acrylic acid Add acrylic acid and deionized water with a total molar weight of 10% into the reaction kettle, stir and dissolve at 15°C to obtain a solution; Water mixed solution, the...

Embodiment 3

[0037] (1) Preparation of hydrophobically modified allyl polyethylene glycol: under nitrogen protection, add 1.0 mol of allyl polyethylene glycol with a molecular weight of 806 into the reaction kettle, stir and heat up to 75°C, add sodium hydroxide As a catalyst, slowly add 1.0mol of 1-bromopentane after reacting for 15min, react at 75°C for 3.5h, add 2.3mol of deionized water, and adjust the pH to 4.8~5.2 with glacial acetic acid, continue to react for 0.5h, react Complete drying to obtain white solid hydrophobically modified allyl polyethylene glycol;

[0038] (2) Preparation of hydrophobically modified viscosity-reducing polycarboxylate superplasticizer: methallyl polyoxyethylene polyoxypropylene ether with a molecular weight of 2084, hydrophobically modified allyl polyethylene glycol, and acrylic acid Add acrylic acid and deionized water with a total molar mass of 8% to the reaction kettle, stir and dissolve at 20°C to obtain a solution; Water mixed solution, the droppin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com