Ceramic grinding aid

A grinding aid and ceramic technology, which is applied in the field of ceramic grinding aids, can solve the problems of lack of water reduction and dispersion effects, inability to improve the flow rate of materials in the mill and electrostatic adsorption in the mill, and improve the grinding efficiency. , the effect of reducing the surface energy of clinker and hindering healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

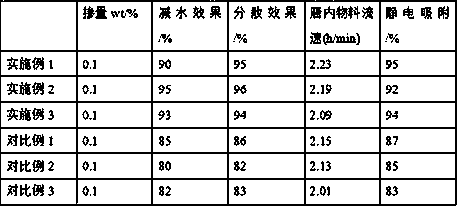

Examples

Embodiment 1

[0028] δ-Layered crystalline sodium disilicate: purchased from Puyang Lvyuan Chemical Co., Ltd.

[0029] Pyrophyllite powder: Take isopropyl tris(dioctyl pyrophosphate acyloxy) titanate and add petroleum ether in a mass ratio of 1:1, stir and mix at 50°C for 30 minutes to obtain a mixture, take pyrophyllite and grind it, crush it 80-mesh sieve, collect the sieved particles, take the mixture and add the sieved particles at a mass ratio of 3:10, heat up to 90°C, stir and mix for 20 minutes, rotary evaporate, and dry to obtain pyrophyllite powder.

[0030]Grinding aid base material: A. Take diisopropanolamine and add N,N-dimethylacetamide in a mass ratio of 1:3, then add diethanolamine with 50% of the mass of diisopropanolamine, stir and mix for 1 hour to obtain a mixture For solution A, take succinic anhydride and add N,N-dimethylacetamide in a mass ratio of 1:8, stir and mix for 40 minutes to obtain a mixed solution B, pass it into nitrogen protection, take the mixed solution A...

Embodiment 2

[0037] δ-Layered crystalline sodium disilicate: purchased from Puyang Lvyuan Chemical Co., Ltd.

[0038] Pyrophyllite powder: take isopropyl tris(dioctyl pyrophosphate acyloxy) titanate and add petroleum ether in a mass ratio of 1:1, stir and mix at 60°C for 40 minutes to obtain a mixture, take pyrophyllite and grind, pulverize 80-mesh sieve, collect the sieved particles, take the mixture and add the sieved particles at a mass ratio of 3:10, heat up to 100°C, stir and mix for 30 minutes, rotary evaporate, and dry to obtain pyrophyllite powder.

[0039] Grinding aid base material: A. Take diisopropanolamine and add N,N-dimethylacetamide in a mass ratio of 1:3, then add diethanolamine with 80% of the mass of diisopropanolamine, stir and mix for 3 hours to obtain a mixture For solution A, take succinic anhydride and add N,N-dimethylacetamide at a mass ratio of 1:8, stir and mix for 50 minutes to obtain a mixed solution B, pass it into nitrogen protection, take the mixed solution ...

Embodiment 3

[0046] δ-Layered crystalline sodium disilicate: purchased from Puyang Lvyuan Chemical Co., Ltd.

[0047] Pyrophyllite powder: Take isopropyl tris(dioctyl pyrophosphate acyloxy) titanate and add petroleum ether in a mass ratio of 1:1, stir and mix at 55°C for 35 minutes to obtain a mixture, take pyrophyllite, grind it, and crush it 80-mesh sieve, collect the sieved particles, take the mixture and add the sieved particles at a mass ratio of 3:10, heat up to 95°C, stir and mix for 25 minutes, rotary evaporate, and dry to obtain pyrophyllite powder.

[0048] Grinding aid base material: A. Take diisopropanolamine and add N,N-dimethylacetamide in a mass ratio of 1:3, then add diethanolamine with a mass ratio of 65% of diisopropanolamine, stir and mix for 2 hours to obtain a mixture For solution A, take succinic anhydride and add N,N-dimethylacetamide in a mass ratio of 1:8, stir and mix for 45 minutes to obtain a mixed solution B, pass it into nitrogen protection, take the mixed sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com