OPLC (Optical Power Line Communication) terminal stripping and fixing seal device and process thereof

A sealing device and terminal technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of optical cable exposure, poor anti-damage ability, easy to be affected by moisture and aging at the stripping branch, and achieve the effect of convenient operation and strong overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

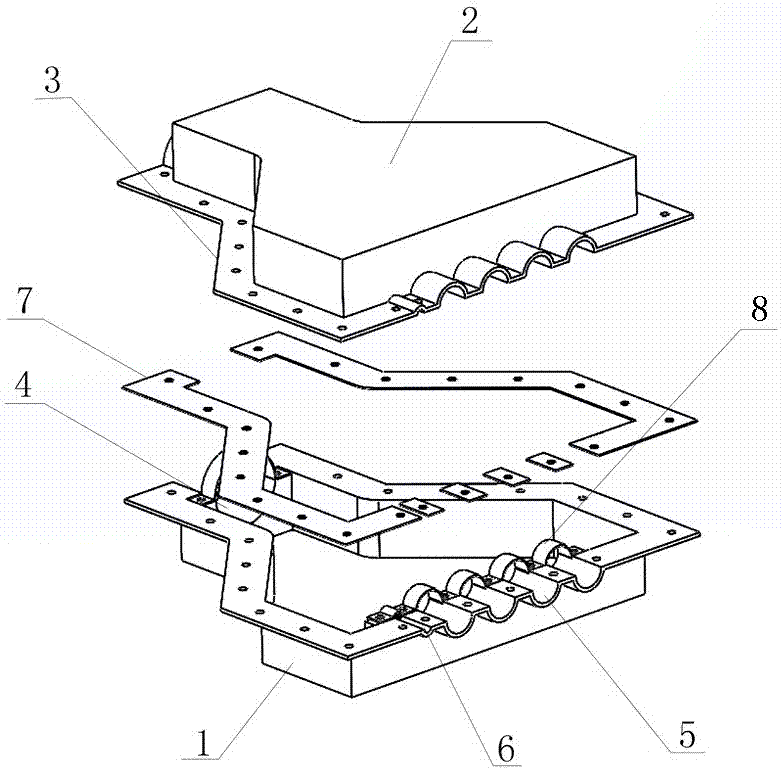

[0025] As shown in the figure, an OPLC terminal peeling, fixing and sealing device of the present invention includes a base 1 and an upper cover 2, and the outer edges of the base 1 and the upper cover 2 are provided with an edge flange 3 extending perpendicular to the side to the outside, and the upper The cover 2 and the base 1 are locked by bolts. One end of the base 1 and the upper cover 2 is provided with a matching OPLC line semicircle groove 4, and the OPLC line semicircle groove 4 of the base 1 and the upper cover 2 is matched up and down to form an OPLC line. Cable hole, the other end of the base 1 and the upper cover 2 is provided with a number of cable outlet semi-circular grooves 5 and a number of optical cable outlet semi-circular grooves 6 that match each other, and the cable outlet semi-circular grooves 5 of the base 1 and the upper cover 2 match up and down correspondingly to form a cable outlet hole , The base 1 and the cable outlet semicircle groove 6 of the u...

Embodiment 2

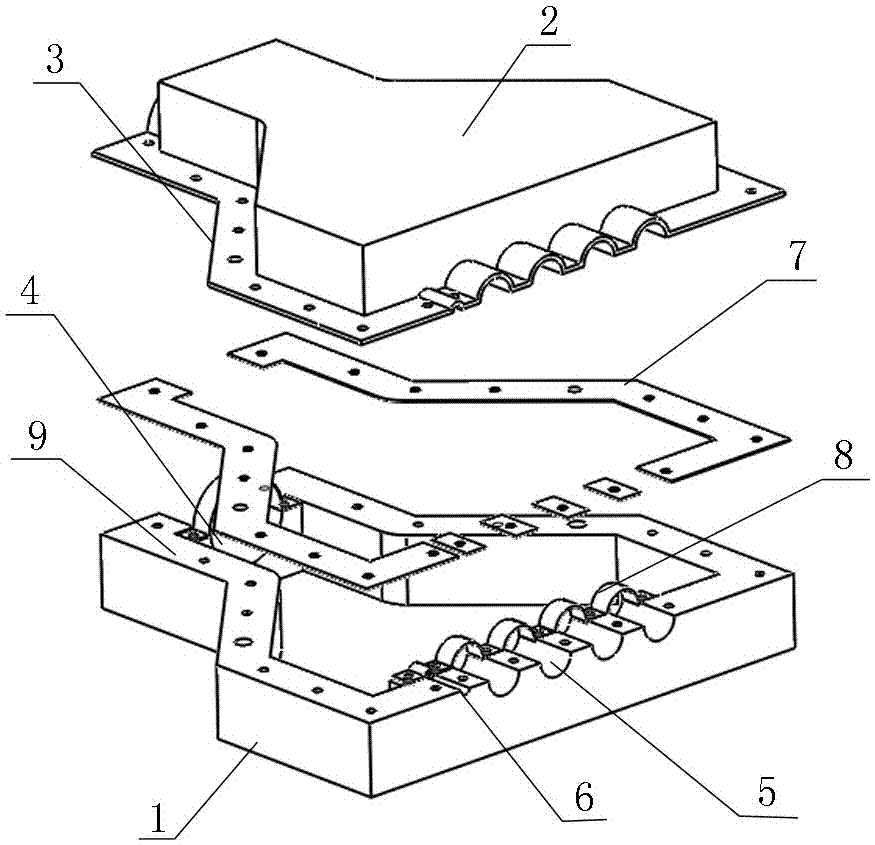

[0035] An OPLC terminal peeling, fixing and sealing device, comprising a base 1 and an upper cover 2, the outer edge of the upper cover 2 is provided with an edge flange 3 perpendicular to the side and extending outward, and the thickness of the side 9 around the base 1 is the same as that of the upper cover 2 edge The width of the flange 3 is matched, and the upper cover 2 and the base 1 are locked by bolts. One end of the base 1 and the upper cover 2 is provided with a matching OPLC cable inlet semicircle groove 4, and the OPLC cable inlet semicircle groove of the base 1 and upper cover 2 4. The upper and lower sides correspond to form the OPLC cable inlet. The base 1 and the other end of the upper cover 2 are provided with a number of cable outlet semi-circular grooves 5 and a number of optical cable outlet semi-circular grooves 6 that match each other. The cable outlet semi-circle grooves 5 of the base 1 and upper cover 2 The upper and lower sides correspond to form the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com