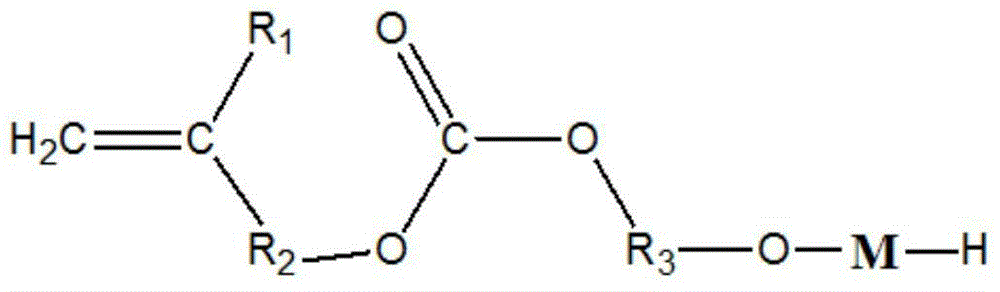

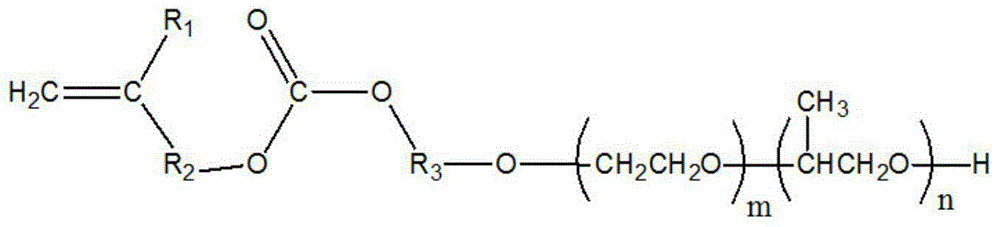

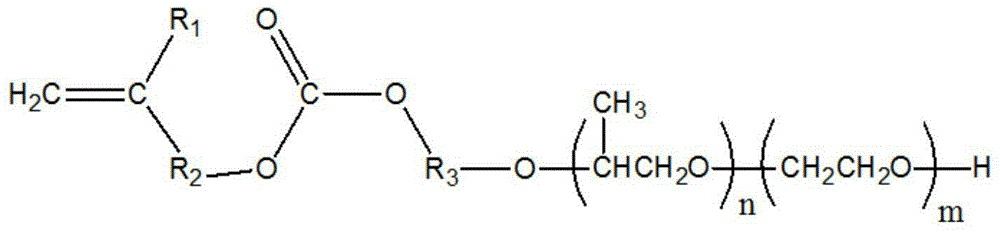

Alkenyl carbonate polyethers, and preparing method and applications thereof

A technology of alkenyl carbonate and polyether, which is applied in the field of alkenyl carbonate polyether and its preparation, can solve the problems that the performance of water reducing agent cannot meet the application needs, and achieve the effects of enhancing toughness, easy degradation, and improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention further provides a kind of preparation method of alkenyl carbonate polyether, and the steps are as follows: add an appropriate amount of initiator and catalyst in the high-pressure reactor (determine the minimum addition of initiator according to the size ratio and the proportioning situation of the reactor , the amount of catalyst is 0.01-0.2% of the finished product), seal the equipment, then replace with nitrogen, and raise the temperature. When the temperature reaches 80-130°C, feed a small amount of alkylene oxide raw material. Add the alkylene oxide raw material in the ratio (determined according to the raw materials of different molecular weights), control the reaction temperature at 60-180°C and the pressure in the kettle at 0.2-0.6MPa, and after the reaction is completed, the pressure in the kettle will gradually drop to no more than 30 minutes continuously. After falling further, the material is aged and cooled to obtain the polyether. Wh...

Embodiment 1

[0043] In the reaction kettle with negative pressure conditions, start stirring, add dimethyl carbonate and sulfuric acid, slowly raise the temperature to 80-90°C, add 1-alkenyl-2-methylhexanol and p-hydroxy Benzyl alcohol. Wherein, the molar ratio of the three reactants is: dimethyl carbonate: 1-alkenyl-2-methylhexanol: p-hydroxybenzyl alcohol=1:1.5:1.5, and the catalyst addition is 0.2% of the total mass of the feed . As the reaction proceeds, the product methanol is continuously discharged from the system. When the methanol no longer flows out, the temperature is lowered for 20 minutes and the material is discharged. According to the difference in boiling point, the product is subjected to vacuum distillation to separate by-products to obtain the carbonate initiator (Formula 1).

[0044] 215 g of carbonate (Formula 1) starter and 1.0 g of KOH were added to the high pressure reactor. Seal the device and replace it with nitrogen 3 times. Start stirring, heat up, and when ...

Embodiment 2

[0048] In the reaction kettle with negative pressure conditions, start stirring, add dimethyl carbonate and sulfuric acid, slowly raise the temperature to 80-90°C, add 1-alkenyl-2-methylhexanol and p-hydroxy Benzyl alcohol. Wherein, the molar ratio of the three reactants is: dimethyl carbonate: 1-alkenyl-2-methylhexanol: p-hydroxybenzyl alcohol=1:1.5:1.5, and the catalyst addition is 0.2% of the total mass of the feed . As the reaction proceeds, the product methanol is continuously discharged from the system. When the methanol no longer flows out, the temperature is lowered for 20 minutes and the material is discharged. According to the difference in boiling point, the product is subjected to vacuum distillation to separate by-products to obtain the carbonate initiator (Formula 1).

[0049] 107 g of carbonate (formula 1) starter and 1.5 g of KOH were added to the high pressure reactor. Seal the device and replace it with nitrogen 3 times. Start stirring, heat up, and when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com