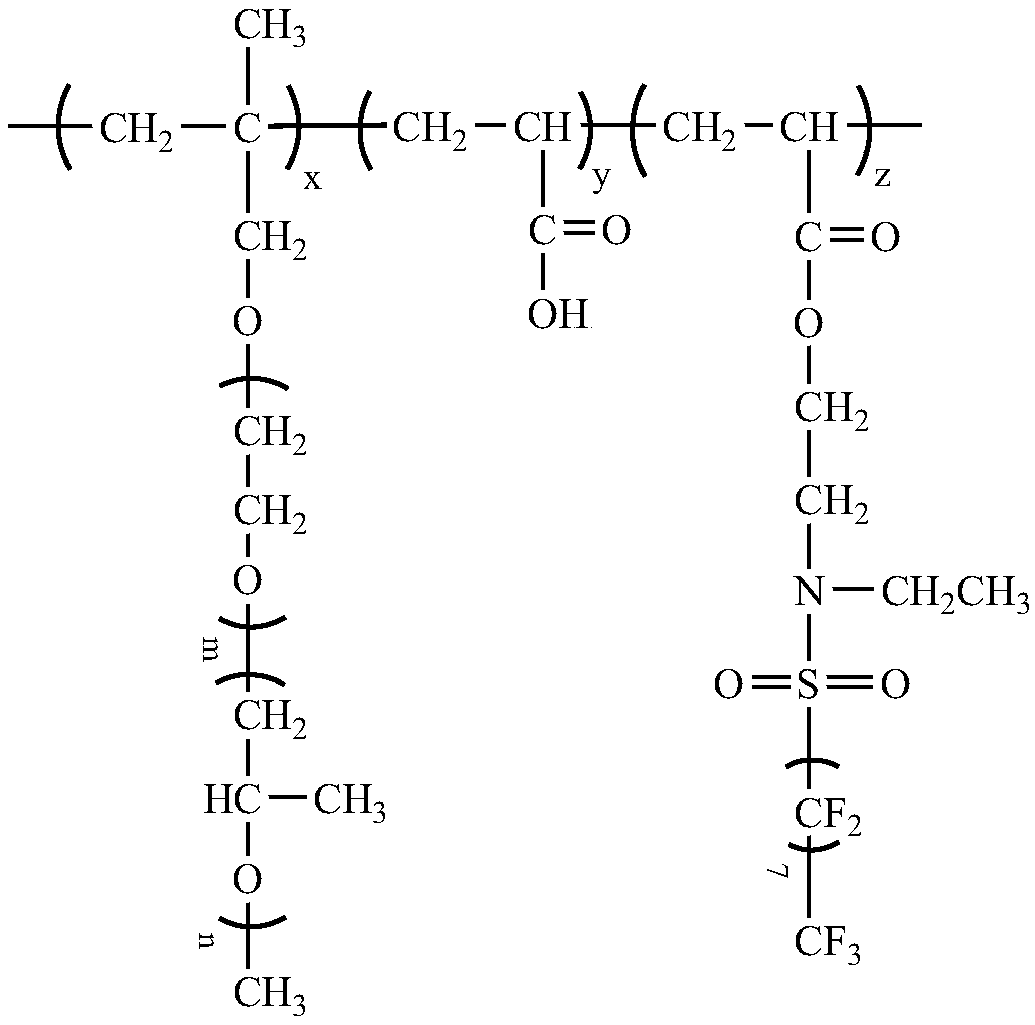

Special high performance concrete polycarboxylate superplasticizer and preparation method thereof

An ultra-high performance, polycarboxylic acid technology, applied in the field of polycarboxylate water reducing agent, can solve the gap, can not meet the problems of ultra-high water-reducing and viscosity-reducing properties of ultra-high-performance concrete, and achieves improved early strength and improved retention. slump capacity, the effect of promoting cement hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

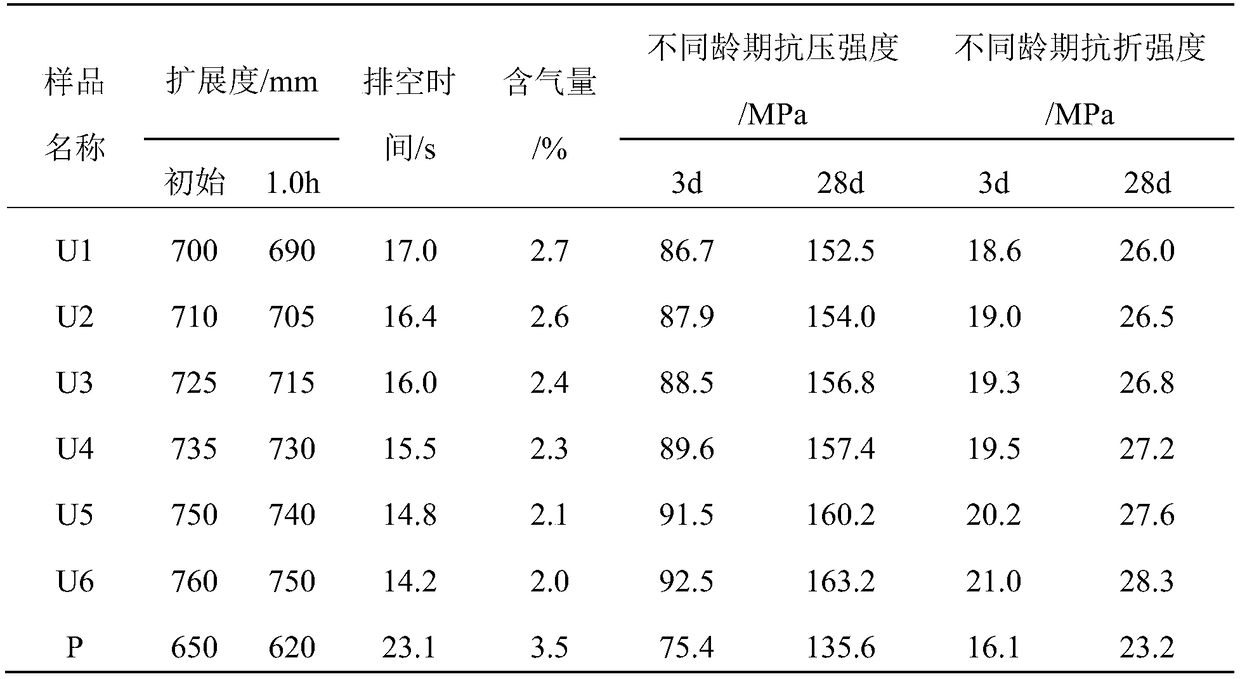

Examples

Embodiment 1

[0031] (1) Synthesis of N-ethyl perfluorooctane sulfonamide acrylate: take benzene as water-carrying agent, concentrated sulfuric acid as catalyst, add N-ethyl perfluorooctane sulfonamide ethanol and acrylic acid in the reactor, Reflux reaction at 110-125°C for 6 hours, heat and distill off the benzene in the reactant after the reaction is completed, cool to room temperature, neutralize the reactant with a mass fraction of 4% sodium hydroxide solution until neutral, then extract with ether, and use The ether layer was washed twice with ionic water, then dried with anhydrous sodium sulfate, and finally the solvent was distilled off under reduced pressure to obtain N-ethyl perfluorooctane sulfonamide acrylate in the form of light yellow liquid. Wherein, the mol ratio of N-ethyl perfluorooctane sulfonamide ethanol and acrylic acid is 1:2;

[0032] (2) Polymerization reaction: Add methallyl polyoxyethylene polyoxypropylene ether with molecular weight of 6000 and m:n of 7:3 and dei...

Embodiment 2

[0034] (1) Synthesis of N-ethyl perfluorooctane sulfonamide acrylate: same as Example 1;

[0035](2) Polymerization reaction: add methallyl polyoxyethylene polyoxypropylene ether with molecular weight of 6000 and m:n of 8:2 and deionized water into the reaction kettle, heat and dissolve at 40-50°C Completely obtain A solution; Add hydrogen peroxide in A solution, and drop the deionized water solution of Bruggolite FF6 reducing agent and the deionized water mixed solution of acrylic acid and N-ethyl perfluorooctane sulfonamide acrylate simultaneously, at 50 Add dropwise at ℃ for 3.0h, keep warm at 50℃ for 1.5h after dripping, cool down to room temperature after the reaction to obtain solution B; ~8, the obtained product is the special polycarboxylate superplasticizer for ultra-high performance concrete, denoted as U2; among them, methallyl polyoxyethylene polyoxypropylene ether, acrylic acid, N-ethyl perfluorooctane sulfonate The molar ratio of amide acrylate, hydrogen peroxid...

Embodiment 3

[0037] (1) Synthesis of N-ethyl perfluorooctane sulfonamide acrylate: same as Example 1;

[0038] (2) Polymerization reaction: add methallyl polyoxyethylene polyoxypropylene ether with a molecular weight of 7000 and m:n of 8:2 and deionized water into the reaction kettle, and heat to dissolve at a temperature of 30-40°C Completely obtain A solution; Add hydrogen peroxide in A solution, and drop the deionized water solution of Bruggolite FF6 reducing agent and the deionized water mixed solution of acrylic acid and N-ethyl perfluorooctyl sulfonamide acrylate simultaneously, at 55 Add dropwise at ℃ for 3.0h, keep warm at 55℃ for 1.5h after dripping, cool down to room temperature after the reaction to obtain solution B; ~8, the obtained product is polycarboxylate superplasticizer for ultra-high performance concrete, denoted as U3; among them, methallyl polyoxyethylene polyoxypropylene ether, acrylic acid, N-ethyl perfluorooctane sulfonate The molar ratio of amide acrylate, hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com