Preparation method of viscosity-reducing type polycarboxylate superplasticizer

A technology of viscous polycarboxylate and water reducer, applied in the field of polycarboxylate water reducer, can solve problems such as lack of designability, environmental pollution, complicated steps, etc., to reduce viscosity and thixotropy, transport Convenience and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

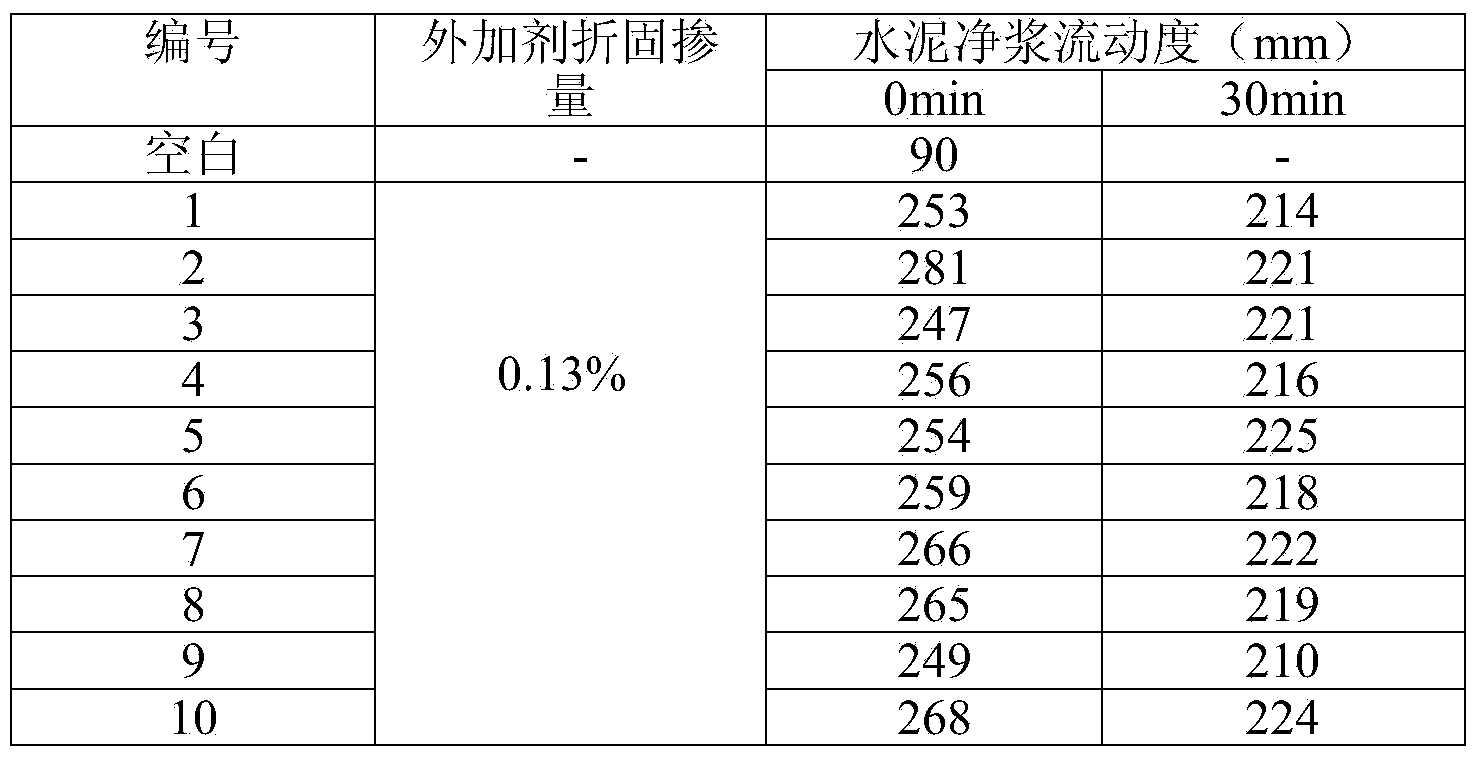

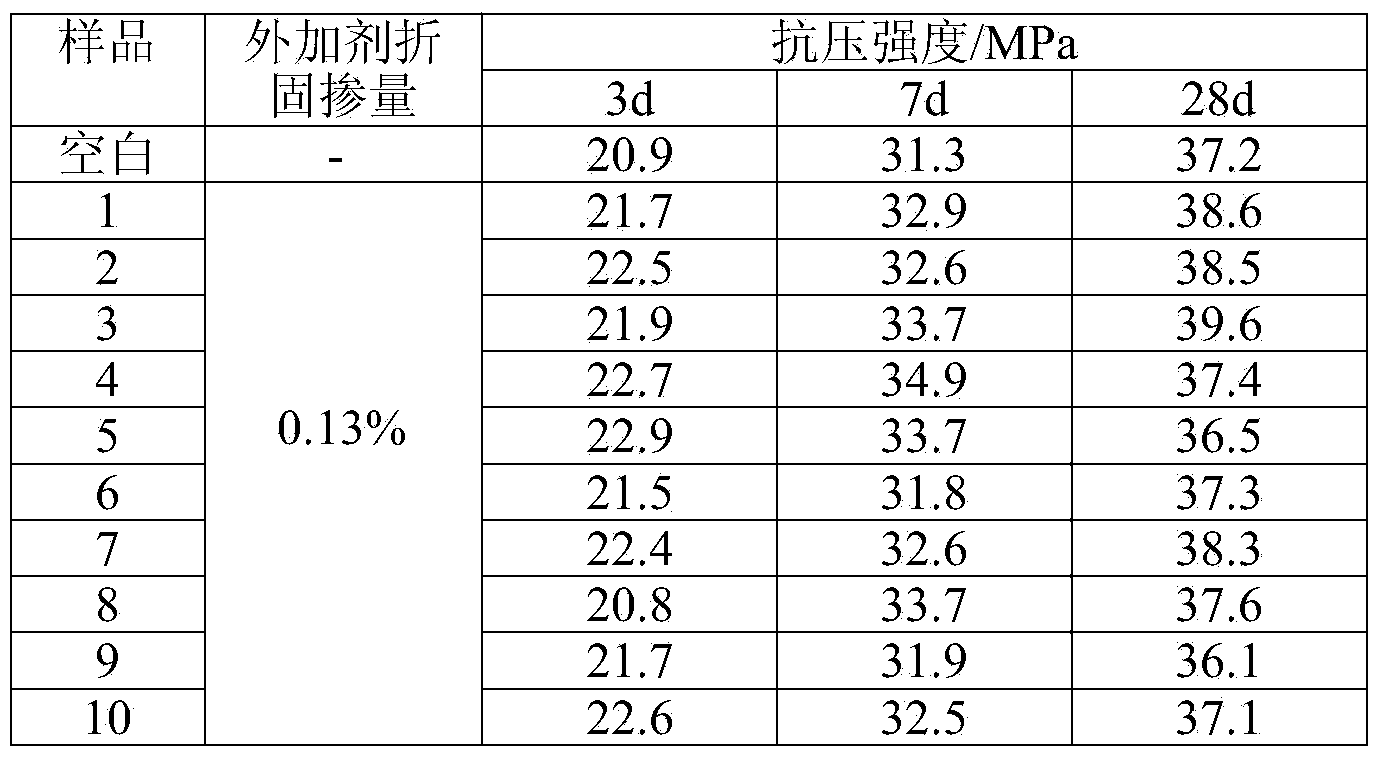

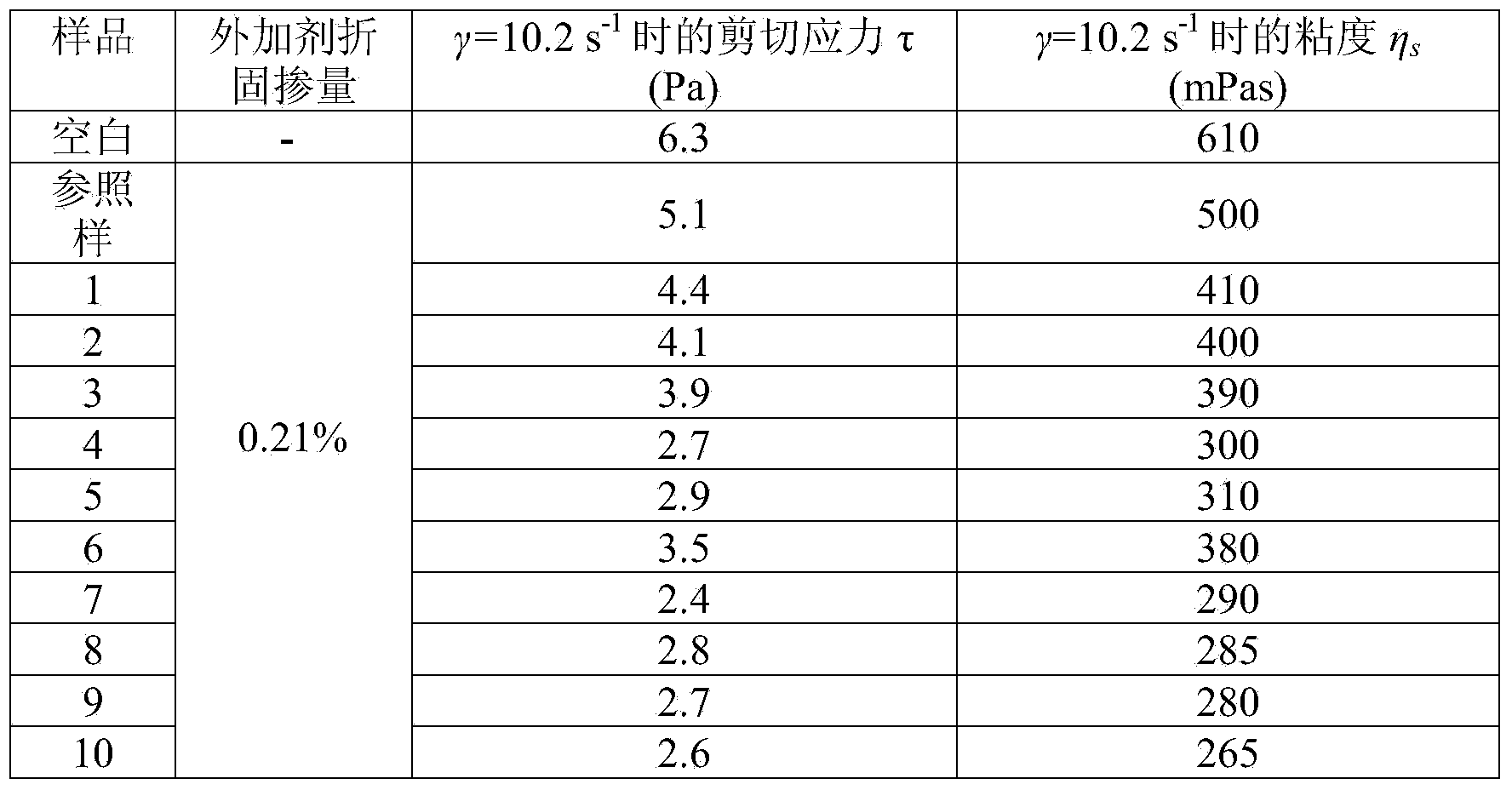

Examples

Embodiment 1

[0024] Step 1) Preparation of small unsaturated primary amine monomers: 1 mol of maleic anhydride and 0.9 mol of dimethylamine were stirred at 5°C for 24 hours to generate small unsaturated primary amine monomers;

[0025] 2) Preparation of small unsaturated monomers of quaternary ammonium salts: add 1.9 mol of ethylene oxide and 0.85 mol of methyl bromide to the reaction system of 1 mol of unsaturated primary amine small monomers generated above and continue to stir at 0°C for 72 hours to obtain the product quaternary Small unsaturated monomers of ammonium salts;

[0026] 3) Preparation of viscosity-reducing water reducer: 20 g of quaternary ammonium salt unsaturated small monomers, 2 g of methyl acrylate, 30 g of acrylic acid and methoxypolyethylene glycol monomethyl ether (meth)acrylate (M n =300g / mol) 300g was first added to the reactor and stirred evenly, then 0.6g hydrogen peroxide and 0.6g mercaptopropionic acid aqueous solution were added dropwise respectively, and the...

Embodiment 2

[0028] Step 1) Preparation of small unsaturated primary amine monomers: Stir 0.1 mol of itaconic anhydride and 0.11 mol of diethylamine at 10°C for 21 hours to generate small unsaturated primary amine monomers;

[0029]2) Preparation of small unsaturated monomers of quaternary ammonium salts: add 2.1 mol of propylene oxide and 1.2 mol of bromoethane to the reaction system of 1 mol of unsaturated primary amine small monomers generated above and continue to stir at 5°C for 60 hours to obtain the product Small unsaturated monomers of quaternary ammonium salts;

[0030] 3) Preparation of viscosity-reducing water reducer: quaternary ammonium salt unsaturated small monomer 30g, ethyl acrylate 10g, sodium acrylate 20g and methoxypolyethylene glycol acrylate (M n =800g / mol) 360g is first added in the reactor, stirred evenly, then respectively dripped ammonium persulfate 0.9g and 3g 2-mercaptopropionic acid aqueous solution, kept temperature 45 ℃, after reacting for 4 hours, obtained c...

Embodiment 3

[0032] Step 1) Preparation of small unsaturated primary amine monomers: Stir 1 mol of fumaric anhydride and 1 mol of diethylamine at 15° C. for 18 hours to generate small unsaturated primary amine monomers;

[0033] 2) Preparation of small unsaturated monomers of quaternary ammonium salts: add 2 mol of 1,2-epoxybutane and 0.85 mol of methyl iodide to the reaction system of 1 mol of unsaturated primary amine small monomers generated above and continue to stir at 10°C for 54 hours Obtain the product quaternary ammonium salt unsaturated small monomer;

[0034] 3) Preparation of viscosity-reducing water reducer: quaternary ammonium salt unsaturated small monomer 10g, butyl acrylate 40g, acrylic amine 30g and polyethylene glycol acrylate (M n =1000g / mol) 300g was first added to the reactor, stirred evenly, then dripped 0.5g of potassium persulfate and 0.1g of 3-mercaptopropionic acid aqueous solution respectively, kept the temperature at 50°C, and reacted for 4.5 hours to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com