Cation modified polycarboxylate superplasticizer and preparation method thereof

A polycarboxylic acid and cation technology, which is applied in the field of cation-modified polycarboxylic acid water reducing agent and its preparation, and building material admixtures, can solve the problems of poor dispersion performance, low adsorption efficiency, unstretched adsorption form, etc. Good dispersion effect, strong adsorption effect and high water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

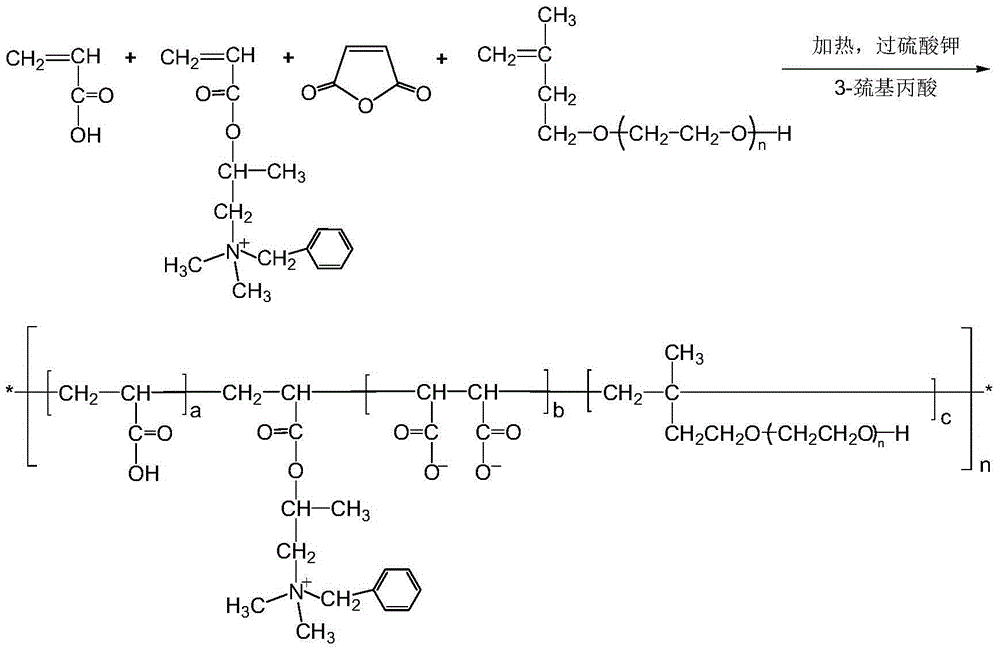

[0031]A cationic modified polycarboxylate water reducer, the preparation method of which comprises the steps of:

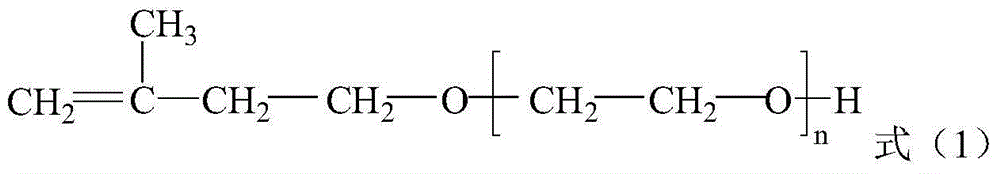

[0032] 1) Accurately weigh 360 g of monomer a isopentenol polyoxyethylene ether, monomer b acrylic acid 25 g, cationic monomer c methacryloyloxyethyl-benzyl-dimethyl ammonium chloride 18 g and monomer d maleic anhydride 10g, initiator potassium persulfate 2g and chain transfer agent 3-mercaptopropionic acid 0.5g;

[0033] 2) In a 1L round bottom flask equipped with a thermometer, stirrer, reflux condenser and nitrogen purging device, add 300g of distilled water and stir, and use nitrogen purging to remove the oxygen in the system, and then pour it into the flask once under the protection of nitrogen. Add 360g isopentenol polyoxyethylene ether (TPEG-2400), stir and dissolve, then heat up to 60°C to obtain aqueous solution A;

[0034] 3) Mix 10g of maleic anhydride, 25g of acrylic acid, 0.5g of 3-mercaptopropionic acid, 18g of (meth)acryloyloxyethyl-benzyl-dimethyl...

Embodiment 2

[0040] A cationic modified polycarboxylate water reducer, the preparation method of which comprises the steps of:

[0041] 1) Accurately weigh 360g of monomer a isopentenol polyoxyethylene ether, 30g of monomer b acrylic acid, 20g of cationic monomer c acryloyloxyethyltrimethylammonium chloride and 8.5g of monomer d itaconic acid , initiator potassium persulfate 4g and chain transfer agent 3-mercaptopropionic acid 0.8g;

[0042] 2) In a 1L round-bottomed flask equipped with a thermometer, stirrer, reflux condenser and nitrogen purging device, add 300g of distilled water, stir, and use nitrogen purging to remove the oxygen in the system, and then pour it into the flask once under the protection of nitrogen. Add 360g isopentenol polyoxyethylene ether (TPEG-2400), stir and dissolve, then heat up to 65°C to obtain aqueous solution A;

[0043] 3) Mix 8.5g of itaconic acid, 30g of acrylic acid, 0.8g of 3-mercaptopropionic acid, 20g of acryloyloxyethyltrimethylammonium chloride and ...

Embodiment 3

[0047] A cationic modified polycarboxylate water reducer, the preparation method of which comprises the steps of:

[0048] 1) Accurately weigh 360 g of monomer a isopentenol polyoxyethylene ether, monomer b methacrylic acid 23 g, cationic monomer c acryloyloxyethyl dimethyl benzyl ammonium bromide 16 g and monomer d horse Toric anhydride 10g, initiator potassium persulfate 2g and chain transfer agent mercaptoacetic acid 0.5g;

[0049] 2) In a 1L round-bottomed flask equipped with a thermometer, stirrer, reflux condenser and nitrogen purging device, add 300g of distilled water, stir, and use nitrogen purging to remove the oxygen in the system, and then pour it into the flask once under the protection of nitrogen. Add 360g isopentenol polyoxyethylene ether (TPEG-2400), stir and dissolve, then heat up to 50°C to obtain aqueous solution A;

[0050] 3) 10g of maleic anhydride, 23g of methacrylic acid, 0.5g of mercaptoacetic acid, 16g of acryloyloxyethyl dimethyl benzyl ammonium br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com