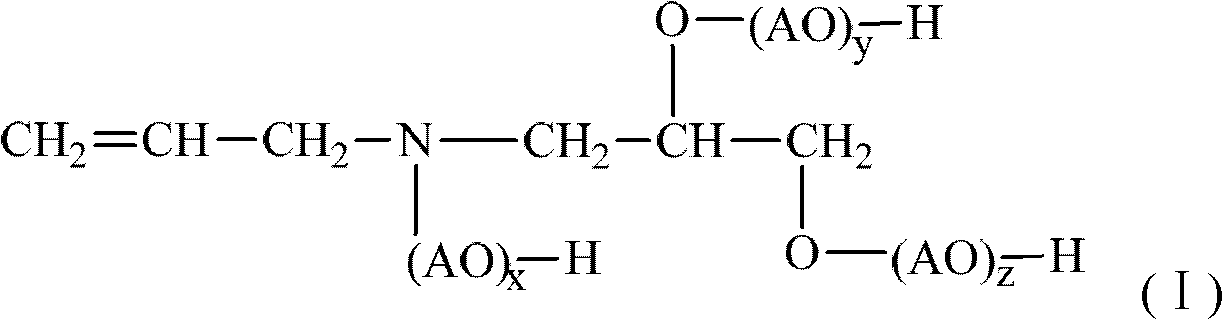

Branching polyether macromonomer and preparation method thereof

A branched polyether and macromonomer technology, applied in the field of reactive polyether synthesis, can solve problems such as limited effect and steric hindrance to be further improved, and achieves improved steric hindrance, high yield, and avoidance of steric hindrance. Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

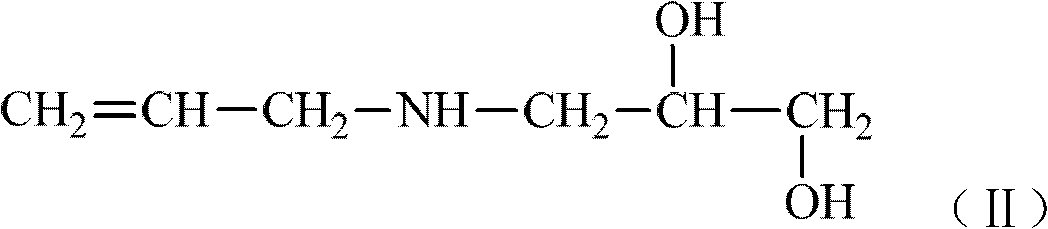

[0027] In a flask with a reflux condenser, a thermometer and a stirrer, add 60.5g of allylamine, place the flask in a water bath at 30°C, stir to keep the temperature constant, then slowly add 74.2g of glycidol dropwise to the flask for 4 hours , After the dropwise addition, continue to keep stirring for 2h, and the reaction ends. Then the temperature of the water bath was raised to 60°C, and the excess allylamine was removed from the product by distillation under reduced pressure, and the product was recovered, and the product remaining in the flask was the intermediate.

[0028] Put 121g of the intermediate synthesized above into a 2L dry stainless steel autoclave, add 0.09g of sodium metal, stir to dissolve, and seal the autoclave. Replace the air in the kettle with nitrogen three times, then evacuate the reactor to below -0.09MPa, turn on the heating, raise the temperature to 120°C, and keep the reactor continuously vacuumed for 30 minutes, then stop, and then continue to ...

Embodiment 2

[0031] In the flask with reflux condenser, thermometer and stirrer, add 71.9g of allylamine, place the flask in a 45°C water bath, stir and keep constant temperature, then slowly add 78.5g of glycidol dropwise to the flask for 6h , After the dropwise addition, continue to insulate and stir for 3h, and the reaction ends. Then the temperature of the water bath was raised to 60°C, and the excess allylamine was removed from the product by distillation under reduced pressure, and the product was recovered, and the product remaining in the flask was the intermediate.

[0032] Put 98g of the above synthesized intermediate in a 2L dry stainless steel autoclave, add 4.9g of potassium hydroxide, stir to dissolve, and seal the autoclave. Replace the air in the kettle with nitrogen three times, then evacuate the reactor to below -0.09MPa, turn on the heating, raise the temperature to 130°C, and keep the reactor continuously vacuumed for 30 minutes, then stop, and then continue to slowly f...

Embodiment 3

[0034] In a flask with a reflux condenser, a thermometer and a stirrer, add 67.3g of allylamine, place the flask in a water bath at 50°C, stir to keep the temperature constant, then slowly add 79.2g of glycidol dropwise to the flask for 8h , After the dropwise addition, continue to insulate and stir for 4h, and the reaction ends. Then the temperature of the water bath was raised to 60°C, and the excess allylamine was removed from the product by distillation under reduced pressure, and the product was recovered, and the product remaining in the flask was the intermediate.

[0035]Put 54g of the intermediate synthesized above into a 2L dry stainless steel autoclave, add 0.56g of sodium hydride, stir to dissolve, and seal the autoclave. Replace the air in the kettle with nitrogen three times, then evacuate the reactor to below -0.09MPa, turn on the heating, raise the temperature to 110°C, and keep the reactor continuously vacuumed for 30 minutes, then stop, and then continue to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com