High water reduction high collapse protection type polycarboxylate high-performance water reducer and pyrogen-free preparation method thereof

A polycarboxylate-based, slump-preserving technology, which is applied in the field of preparation of polycarboxylate-based high-performance water reducers and water reducers, can solve the problems of cement adaptability, high production costs, and increased energy consumption. And equipment investment and other issues, to achieve the effect of cement wide adaptability, easy reaction process, workability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

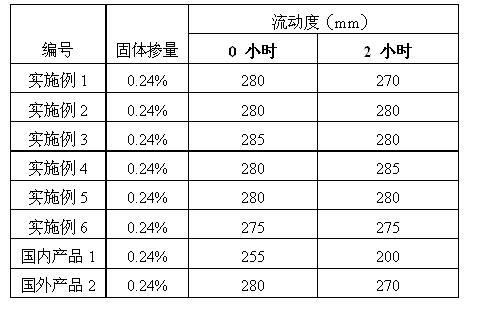

Examples

Embodiment 1

[0032] Prepare high water-reducing and high-slump retention type polycarboxylate high-performance water-reducing agent according to the following raw material quantity and process, specifically:

[0033] The first step, material preparation: add 0.8 g of L-ascorbic acid to 20 g of deionized water, mix evenly, reserve tank A as material A; add 5.5 g of acrylic acid, 0.15 g of hydroxyethyl acrylate, and 0.2 g of thioglycolic acid, add 80 g In deionized water, mix evenly, and reserve the B tank, which is the B material;

[0034] The second step, polymerization: add 168 g of deionized water and unsaturated methyl alkenyl polyoxyethylene ether (M W =3000) 60 g, after fully dissolved by stirring, add H with a mass concentration of 30% 2 o 2 1 g and 0.2 g of potassium persulfate, stir evenly, keep the temperature to 20 ℃, add material A and material B dropwise at the same time, add material A dropwise for 3 hours, add material B dropwise for 2.5 hours, and keep warm for 3 hours af...

Embodiment 2

[0036] Prepare high water-reducing and high-slump retention type polycarboxylate high-performance water-reducing agent according to the following raw material quantity and process, specifically:

[0037] The first step, material preparation: Add 0.9 g of L-ascorbic acid to 20 g of deionized water, mix evenly, and reserve the A tank as material A; 7.25 g of acrylic acid, 0.45 g of itaconic acid, 2-acrylamide-2-methyl Add 0.13 g of propylene sulfonic acid and 0.65 g of sodium methpropylene sulfonate into 60 g of deionized water, mix evenly, and reserve tank B as material B;

[0038] The second step, polymerization: add 81 g of deionized water, unsaturated methyl alkenyl polyoxyethylene ether (M W =2400) 60 g, after fully dissolved by stirring, add 30% H 2 o 2 1.25 g, stir evenly, keep the temperature to 25 ℃, and continuously add materials A and B dropwise at the same time, add material A dropwise for 3.5 hours, add material B dropwise for 3 hours, and react for 3 hours after ...

Embodiment 3

[0040] Prepare high water-reducing and high-slump retention type polycarboxylate high-performance water-reducing agent according to the following raw material quantity and process, specifically:

[0041] The first step, material preparation: Add 0.4 g of sodium bisulfite to 20 g of deionized water, mix evenly, and use tank A for spare use, which is material A; 2.5 g of methacrylic acid, 7.5 g of maleic anhydride, 1.75 g of acrylamide, Add 0.25 g of sodium propylsulfonate to 40 g of deionized water, mix evenly, and reserve tank B for use as material B;

[0042] The second step, polymerization: add 50 g of deionized water and unsaturated methyl alkenyl polyoxyethylene ether (M W =2400) 60 g, after fully dissolved by stirring, add 0.8 g of ammonium persulfate, stir evenly, keep the temperature to 30 ℃, add A and B material dropwise at the same time, add material A dropwise for 4 hours, add material B dropwise for 3 hours, add material A dropwise After the dropwise addition, reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com