Process for extracting sodium alginate

A sodium alginate and extraction process technology, applied in the field of sodium alginate extraction process, can solve the problems of low product viscosity, environmental pollution, low extraction rate of production process, etc., and achieve good performance, high purity, and improved extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Pretreatment process: Soak kelp in an appropriate amount of 0.5% V formaldehyde aqueous solution at 25°C for 1 hour, then filter and rinse the kelp with purified water until the filtrate is colorless, and monitor the conductivity of the filtrate to 20-30us / cm, stop washing, and then crushed to an area of 1 cm 2 ~2cm 2 Then add purified water of 4 times the weight of kelp to the fragments, and use a high-speed shear to shear the fragments at 800-1000 rpm to make the fragments into a slurry;

[0033] 2) Enzymolysis process: Add neutral cellulase, neutral protease, and alkaline pectinase to the slurry solution obtained in step 1, and then add 0.2Mol / L sodium dihydrogen phosphate with a volume ratio of 1:1 Mix the solution with 0.2Mol / L disodium hydrogen phosphate to control the pH of the system between 6 and 7, perform enzymatic hydrolysis at 18°C for 2 hours, then control the temperature to 28°C, and adjust the pH with 0.2Mol / L sodium dihydrogen phosphate After ...

Embodiment 2

[0041] 1) Pretreatment process: Soak the brown algae in an appropriate amount of 0.5% V formaldehyde aqueous solution at 35°C for 2 hours, then filter and rinse the brown algae with purified water until the filtrate is colorless, and monitor the conductivity of the filtrate to 20-30us / cm, stop washing, and then crushed to an area of 1 cm 2 ~2cm 2 Then add purified water of 5 times the weight of kelp to the fragments, and use a high-speed shearing machine to cut the fragments at 800-1000rpm to make the fragments into a slurry;

[0042] 2) Enzymolysis process: Add neutral cellulase, neutral protease, and alkaline pectinase to the slurry solution obtained in step 1, and then add 0.2Mol / L sodium dihydrogen phosphate with a volume ratio of 1:1 Mix the solution with 0.2Mol / L disodium hydrogen phosphate to control the pH of the system between 6 and 7, perform enzymatic hydrolysis at 35°C for 3 hours, then control the temperature to 32°C, and adjust the pH with 0.2Mol / L sodium dih...

Embodiment 3

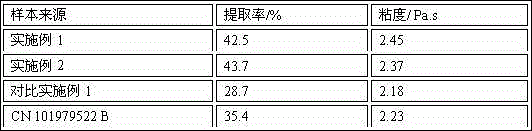

[0052] The sodium alginate in Example 1 and Example 2 was detected with reference to GB1976-80, wherein three samples were taken for each example, and the average value was taken. The test results are as follows:

[0053]

[0054] Note: CN 101979522 B represents sodium alginate extracted according to the teaching in CN 101979522 B.

[0055] GB1976-80 stipulates that the viscosity of sodium alginate / Pa.s is greater than 0.15. The samples prepared by the present invention and its CN 101979522 B all meet the requirements, but the prepared by the present invention has a higher viscosity and a higher extraction rate. And the comparative examples show that the addition of β-agarase can promote the extraction rate and viscosity of sodium alginate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com