Method for extracting fucoxanthin from brown algae

A technology of fucoxanthin and brown algae, applied in the direction of non-central analgesics, animal feed forming or processing, anti-toxic agents, etc., can solve the problems of skin tingling, skin burns, time-consuming and labor-intensive, and achieve simple and easy operation line, easy to industrial production, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

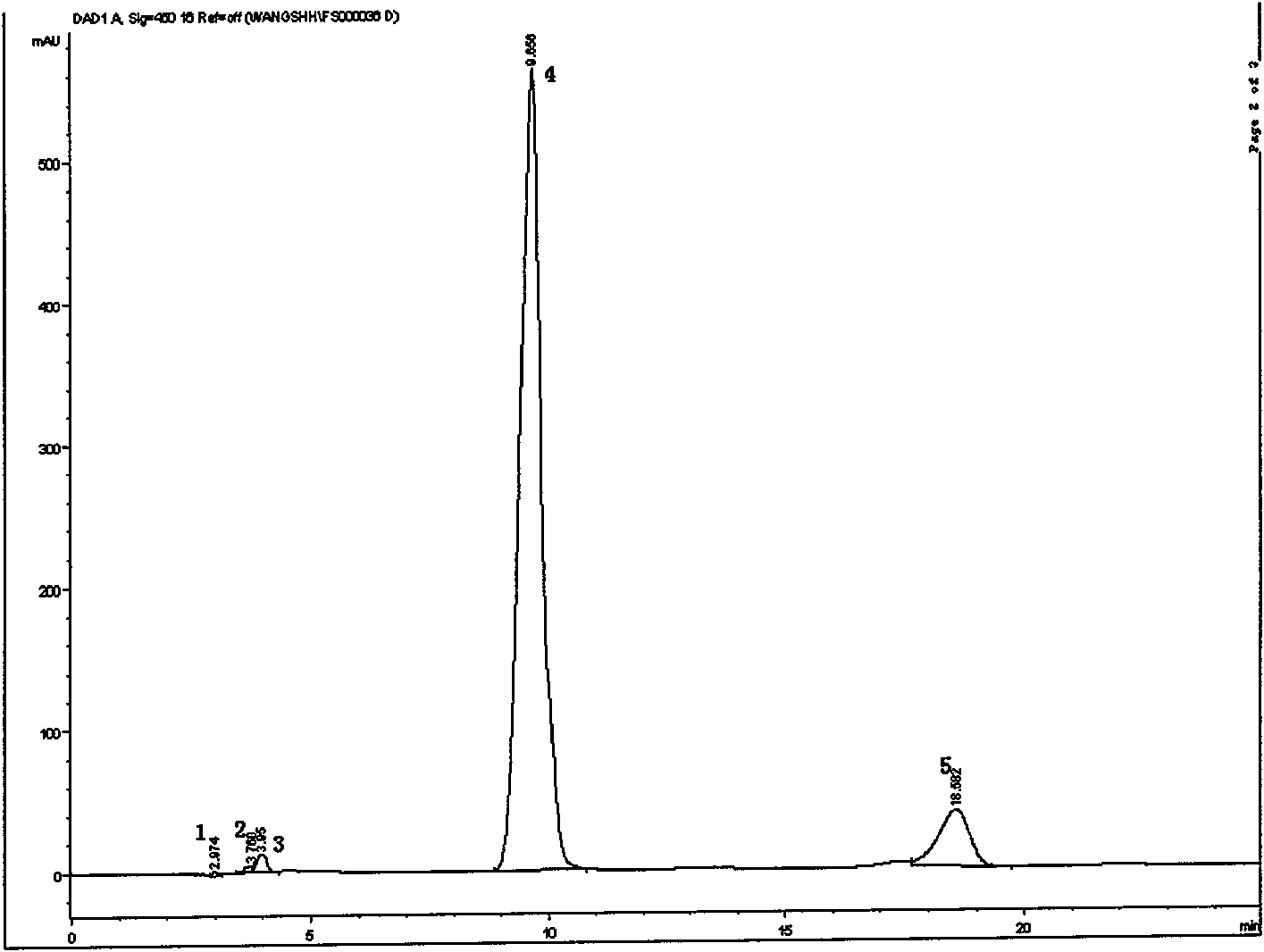

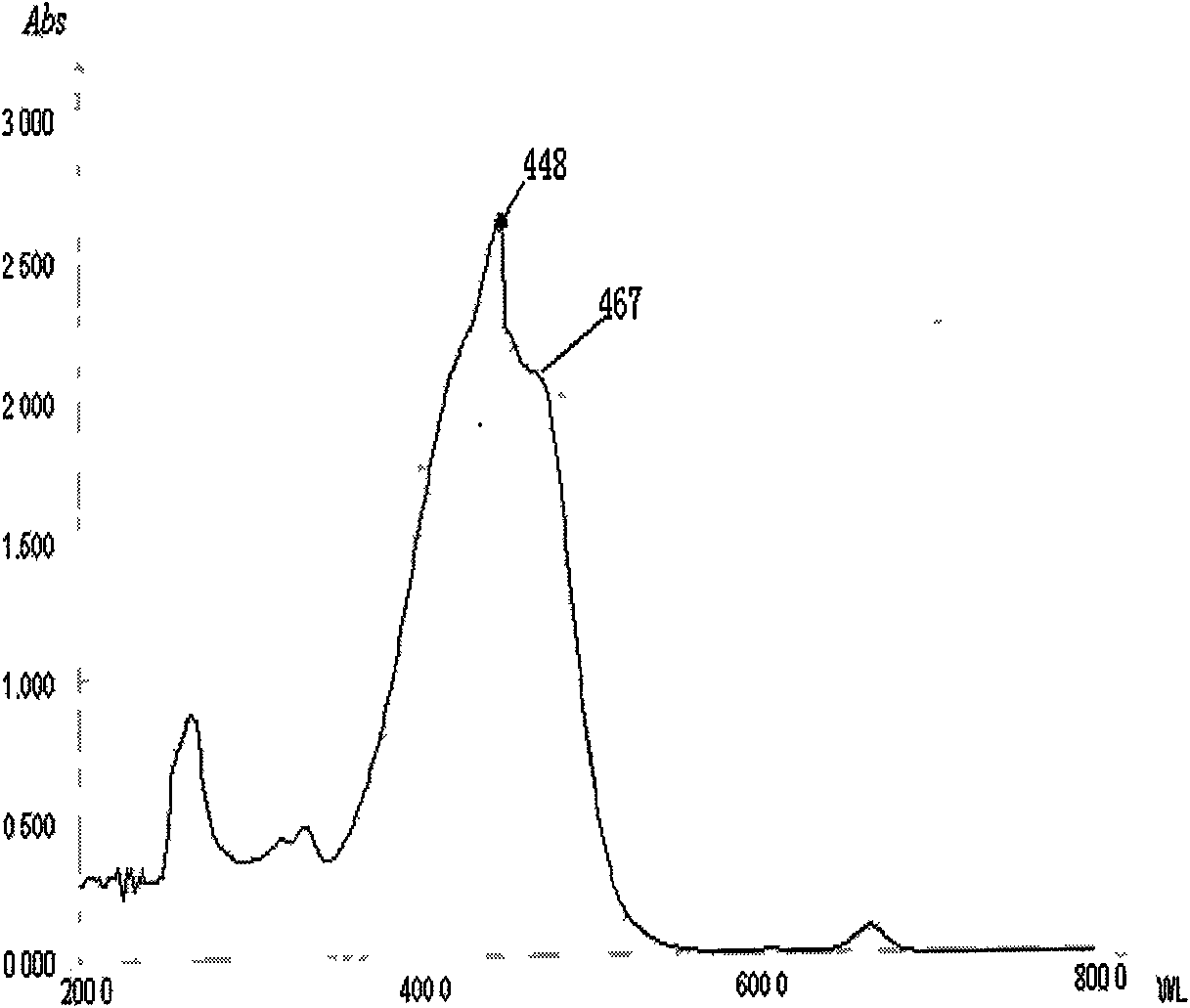

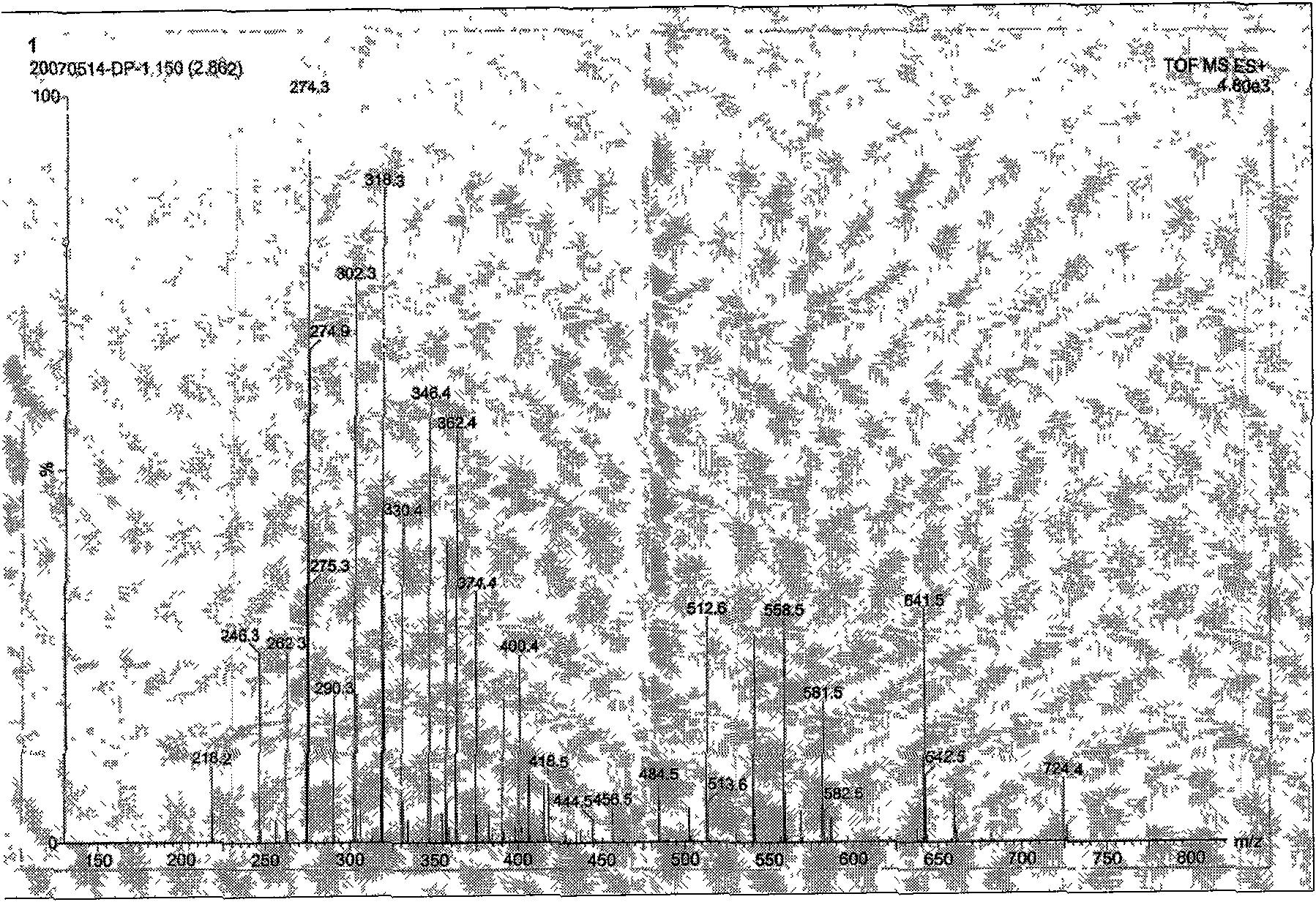

[0014] Drain 1kg of wakame seaweed, cut it into pieces, add water and stir it into a slurry, pour it into a brown bottle, add 500ml of acetone reagent every day, then add 1g of MgCO3 powder to prevent oxidation, leaching at low temperature in the dark, and let it stand After 24 hours, the acetone extract was filtered out with a Buchner funnel, and the extraction was repeated for 12 days until the acetone layer was colorless. Combine each acetone extract into a brown bottle, remove the acetone by rotary evaporation, then add ethyl acetate to the rotary evaporator to dissolve the adherents, transfer it into a separatory funnel, and then add distilled water of the same volume as ethyl acetate to shake Separate layers, take the ethyl acetate layer, repeat 3 times, combine the ethyl acetate layers and concentrate by rotary evaporation to obtain the total pigment of wakame. The concentrated fucoxanthin-containing ethyl acetate extract was subjected to silica gel column chromatograph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com