Method for extracting algin through comprehensively utilizing brown algae

A technology of alginate and brown algae, applied in the fields of application, food preparation, food science, etc., can solve the problems of poor quality, low yield of alginate, large water consumption of alginate, etc., and achieve high yield, high degree of equipment automation, The effect of improving the overall utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

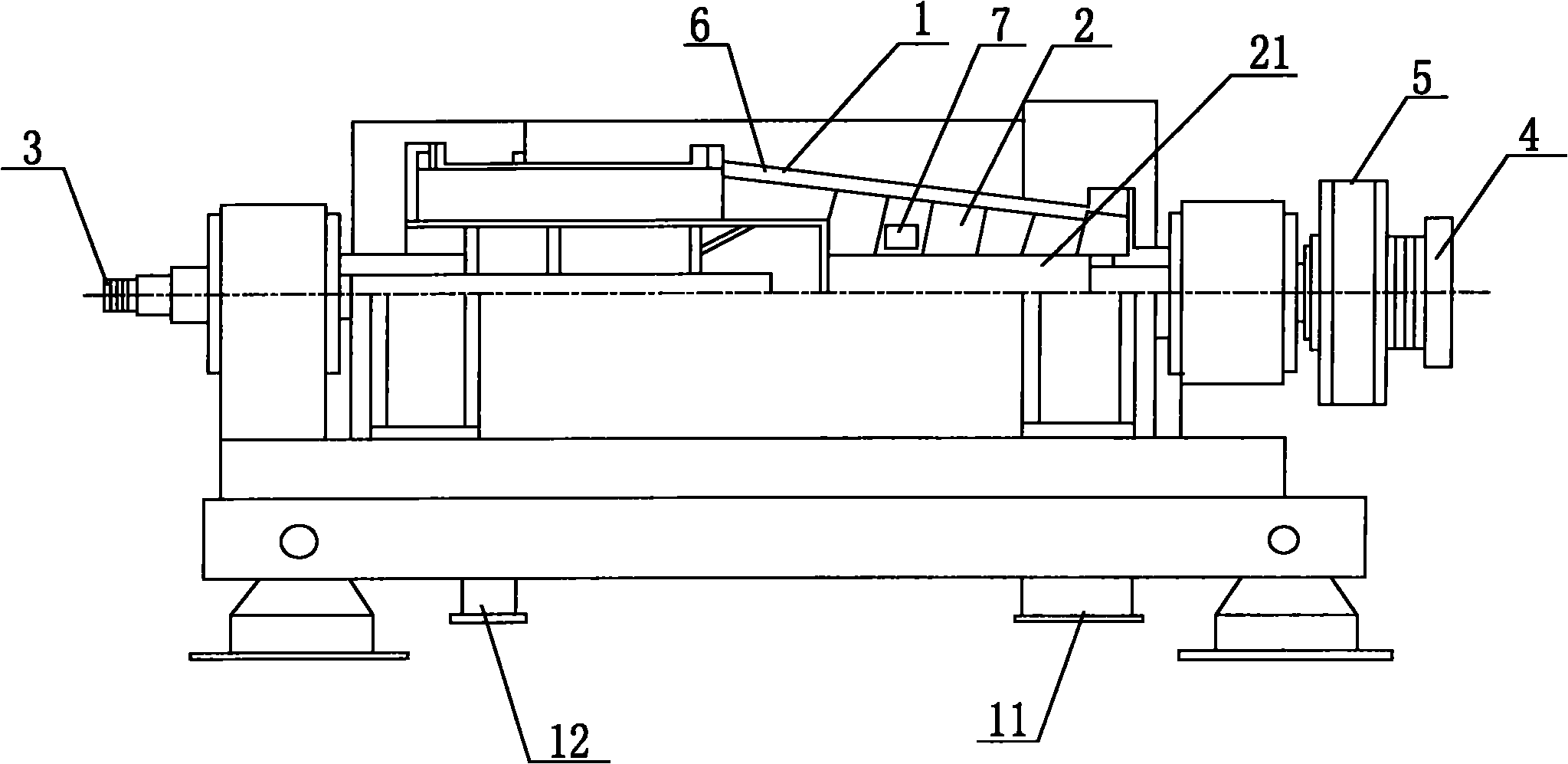

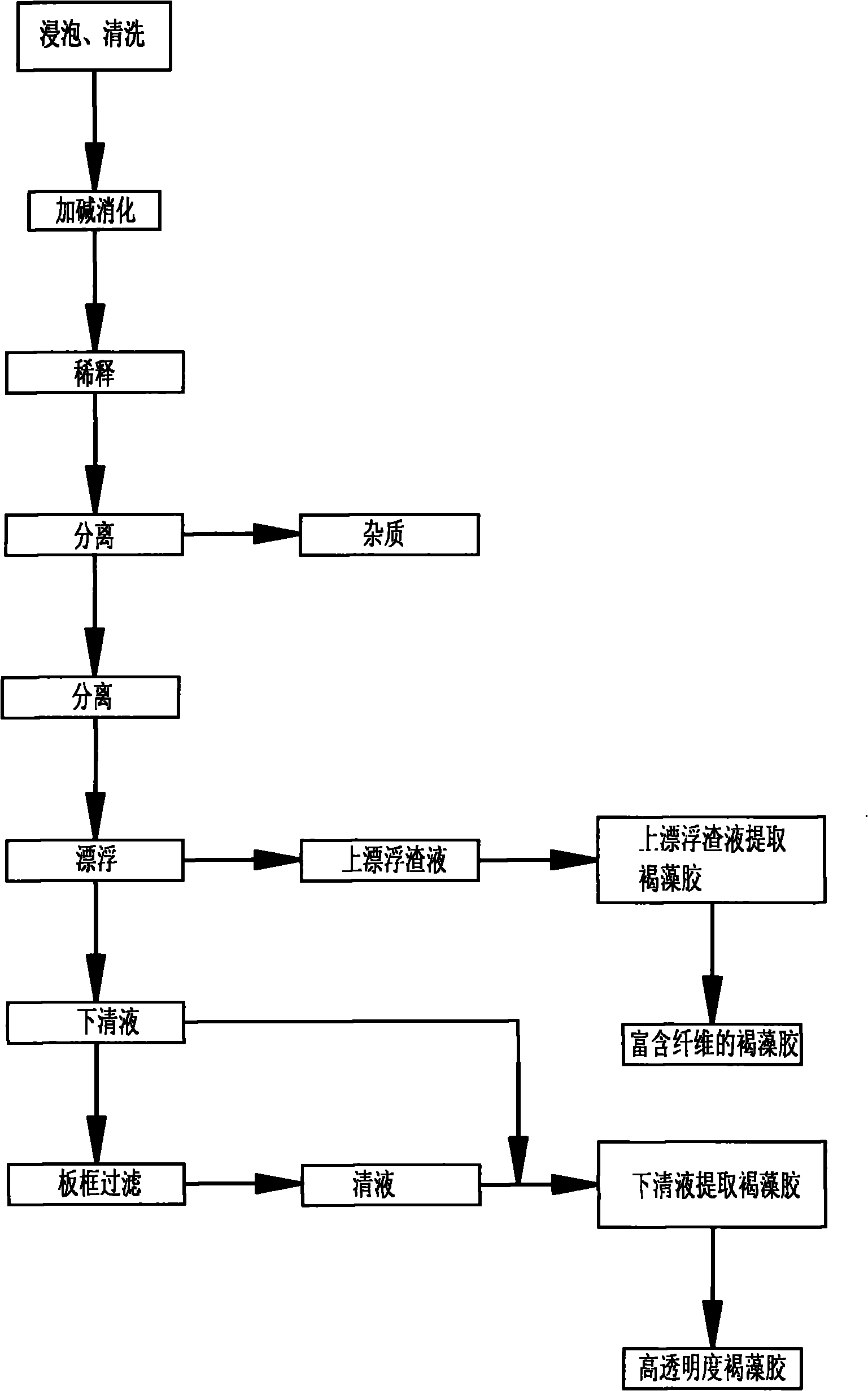

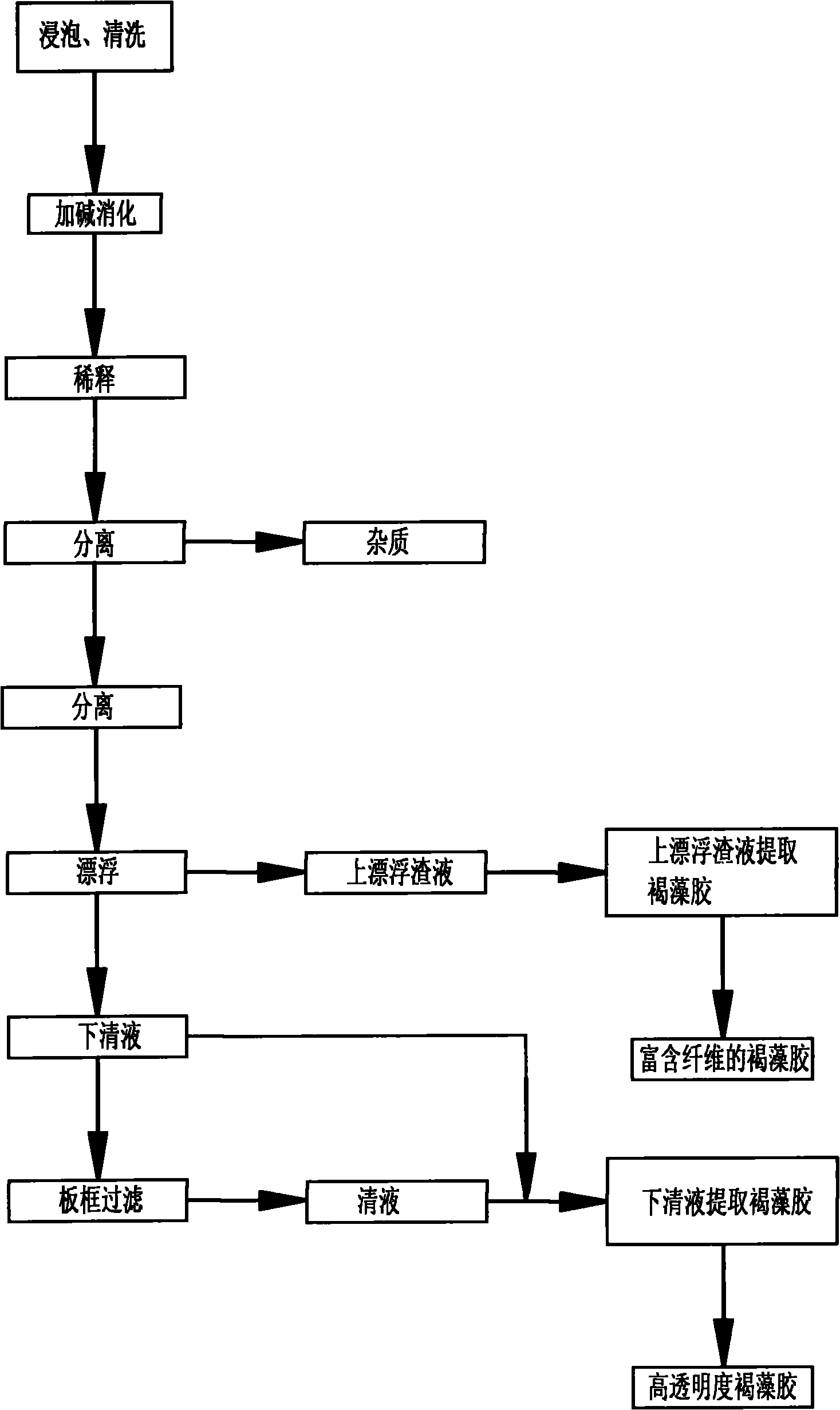

[0039] refer to figure 1 with figure 2 As shown, a method for extracting alginate by comprehensive utilization of brown algae, the process steps include (1) soaking and cleaning; (2) adding soda ash for digestion; (3) dilution; (4) separation; (5) slag liquid extraction; (6) ) supernatant liquid extraction; step (4) adopts horizontal screw centrifuge, horizontal screw centrifuge comprises drum 1, has the feeding screw 2 of inner tube 21, feed pipe 3 that is communicated with feeding screw inner tube 21, The slag discharge port 11 and overflow port 12, the power unit 4 and the differential gear 5 are respectively located at the end of the drum 1; the conveying screw 2 is located inside the drum 1, and a separation cavity for material separation is formed between them 6. The feeding screw 2 is provided with a distributing port 7 for feeding the material entering from the feeding pipe 3 into the separation cavity 6 between the feeding screw 2 and the drum 1, driven by the power...

Embodiment 2

[0053] ①Soaking and cleaning: 1 ton of dried kelp, add 12m 3 Soak in tap water for 2.5 hours, after controlling the water, use a vegetable cutter to cut to about 10cm long, add 5m 3 After washing with tap water, control the water, and wash 3 times in this way;

[0054] ② Digestion: Control the water of the soaked kelp, put it into the digestion tank, add 3m 3 Tap water, stirring and adding 120kg of sodium carbonate, heating to 50°C for heat preservation and stirring for 3 hours for digestion reaction to obtain kelp digestion glue;

[0055] ③Dilution: Add tap water to the kelp digestive glue, stir and dilute until the Engler's viscosity is 160 seconds, and then dilute the digestive glue;

[0056] ④Separation: Use LW530 horizontal spiral centrifuge, set its processing capacity to 50m 3 / h, the addition of chitin flocculant with mass percent concentration of 0.3‰ is set to 1m 3 / h, the rotational speed of the drum is set to 2700r / min, the differential speed between the drum a...

Embodiment 3

[0062] ①Soaking and cleaning: 1 ton of dried macroalgae crushed particles, add 15m 3 Soak in tap water for 12 hours to swell completely, control water, add 5m 3 Wash with tap water and control the water, so wash 4 times;

[0063] ② Digestion with alkali: add the soaked macroalgae into the digestion tank, add 5m 3 Tap water, stir and add 200kg of sodium carbonate, heat to 60°C and keep warm, stir and digest for 10 hours to obtain macroalgae digested glue;

[0064] ③Dilution: add macroalgae digestive glue to tap water, stir and dilute to Engler's viscosity of 180 seconds, and then dilute the digestive glue;

[0065] ④Separation: Use LW530 horizontal screw centrifuge, set its processing capacity to 40m 3 / h, the addition of chitin flocculant whose mass percentage concentration is 1‰ is set to 3m 3 / h, the rotating speed of the drum is set at 2500r / min, and the differential speed of the drum and the feeding screw is set at 20r / min, and all the other are the same as the descrip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com