Method for producing sodium alginate by applying brown algae

A technology of sodium alginate and brown algae, which is applied in the field of marine chemical industry, can solve the problems of formaldehyde solution poisoning the body and the environment, rising costs, and increasing energy consumption, and achieve the effects of shortening pretreatment time, saving energy, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for producing sodium alginate using brown algae, characterized in that one of the brown algae: giant algae is treated by Fenton method to obtain a processed product, and sodium alginate is extracted from the processed product.

[0030] The specific process of using the Fenton method to treat macroalgae includes:

[0031] The macroalgae is immersed in the ferrous ion solution, so that the mass ratio of the mass of the macroalgae in the ferrous iron solution to the ferrous ion is 500:1, and then the hydrogen peroxide solution is added to the ferrous ion solution, so that The molar ratio of ferrous ions and hydrogen peroxide in the mixed solution is not less than 1:1, and the treatment lasts for 10 minutes.

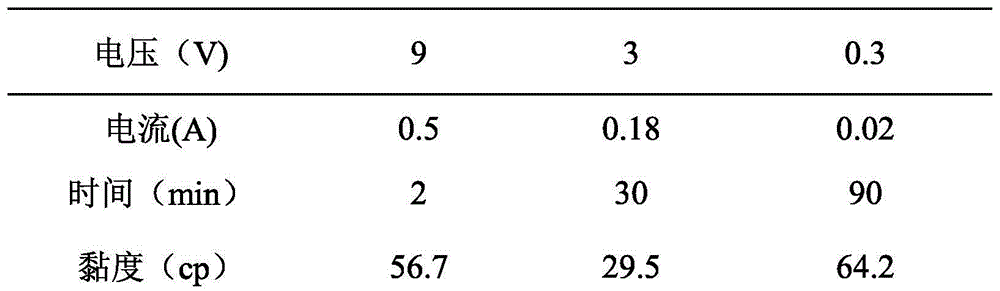

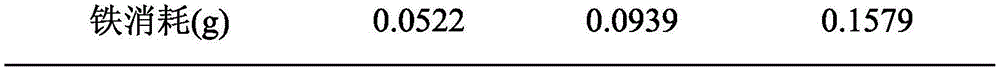

[0032] The Fenton method is an electric Fenton method, and the specific process of using the electric Fenton method to process giant algae includes:

[0033] The macroalgae was placed in the hydrochloric acid solution, and the hydrochloric acid solution cont...

Embodiment 2

[0046] A method for producing sodium alginate using brown algae is characterized in that one of the brown algae: kelp is treated by the Fenton method to obtain a processed product, and sodium alginate is extracted from the processed product.

[0047] The specific process of processing kelp using the Fenton method includes:

[0048] Soak the kelp in the ferrous ion solution so that the mass ratio of the kelp in the ferrous solution to the ferrous ion is 200:1, and then add hydrogen peroxide solution to the ferrous ion solution to make the mixed solution The molar ratio of ferrous ions and hydrogen peroxide in the medium is not lower than 2:1, and the treatment lasts for 40 minutes.

[0049] Described Fenton's method is electric Fenton's method, utilizes the specific process of electric Fenton's method to process kelp comprising:

[0050] The kelp is placed in the hydrochloric acid solution, and the hydrochloric acid solution containing the kelp is electrolyzed by using an elec...

Embodiment 3

[0063] A method for producing sodium alginate using brown algae, characterized in that one of the brown algae: giant algae is treated by Fenton method to obtain a processed product, and sodium alginate is extracted from the processed product.

[0064] The specific process of using the Fenton method to treat macroalgae includes:

[0065] The macroalgae is immersed in the ferrous ion solution, so that the mass ratio of the mass of the macroalgae in the ferrous iron solution to the ferrous ion is 500:1, and then the hydrogen peroxide solution is added to the ferrous ion solution, so that The molar ratio of ferrous ions and hydrogen peroxide in the mixed solution is not less than 1:1, and the treatment lasts for 10 minutes.

[0066] The Fenton method is an electric Fenton method, and the specific process of using the electric Fenton method to process giant algae includes:

[0067] The macroalgae was placed in the hydrochloric acid solution, and the hydrochloric acid solution cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com