City domestic refuse plastic sorting process and device

A municipal solid waste and plastic technology, applied in plastic recycling, solid separation, mechanical material recycling, etc., can solve the problems of waste plastic white pollution, achieve high plastic sorting rate, improve garbage sorting rate, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

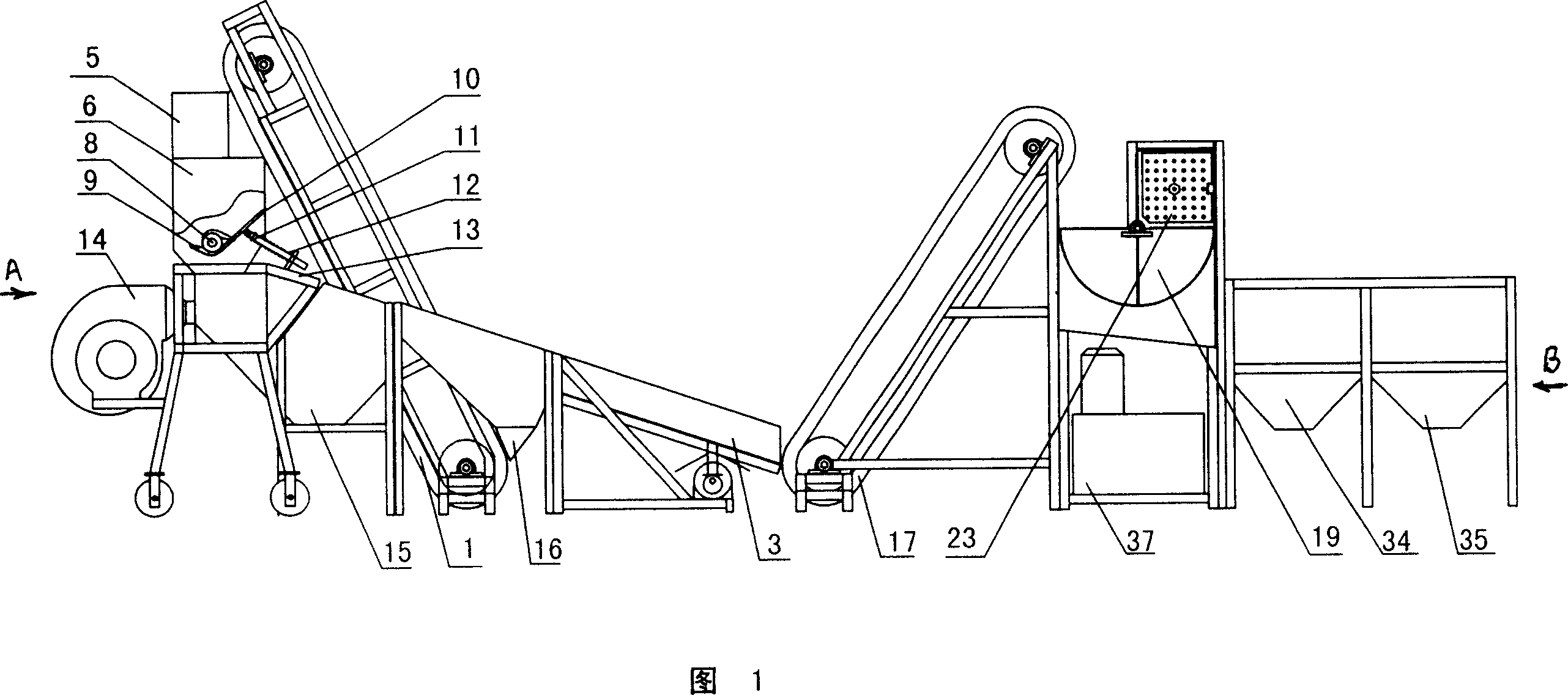

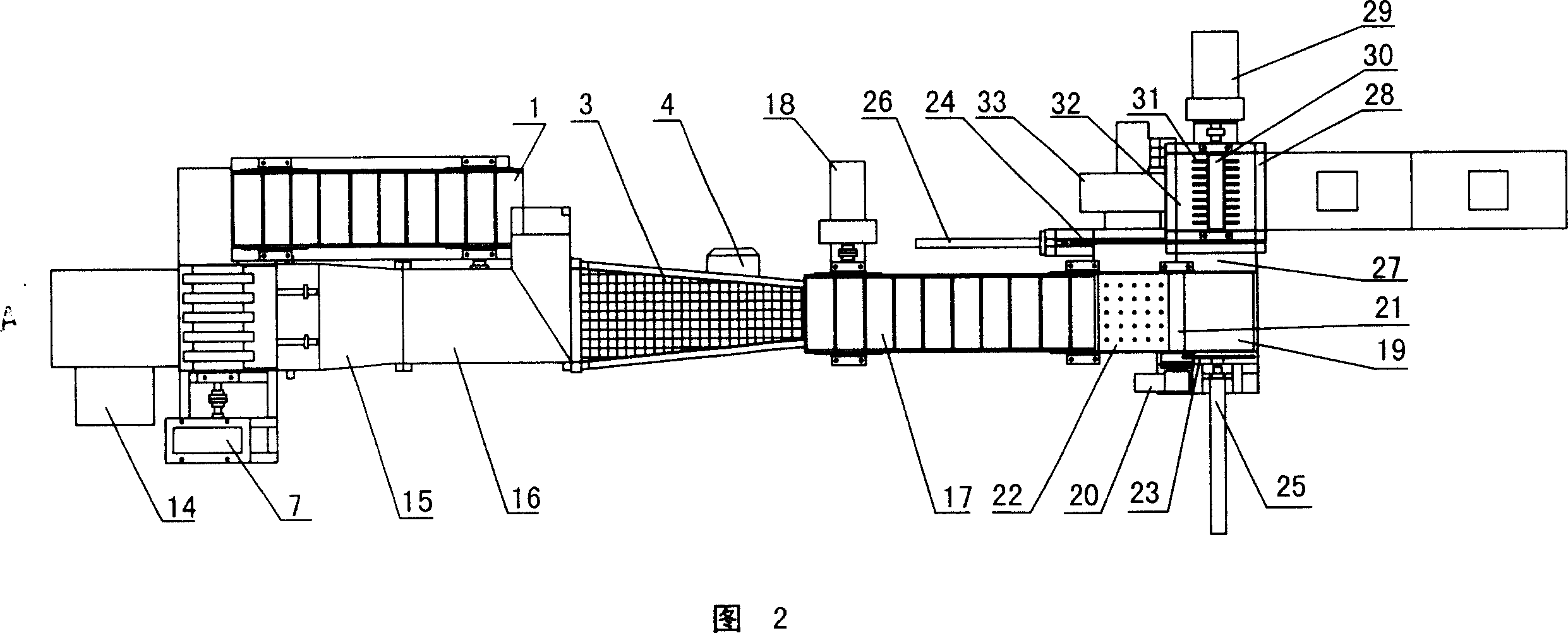

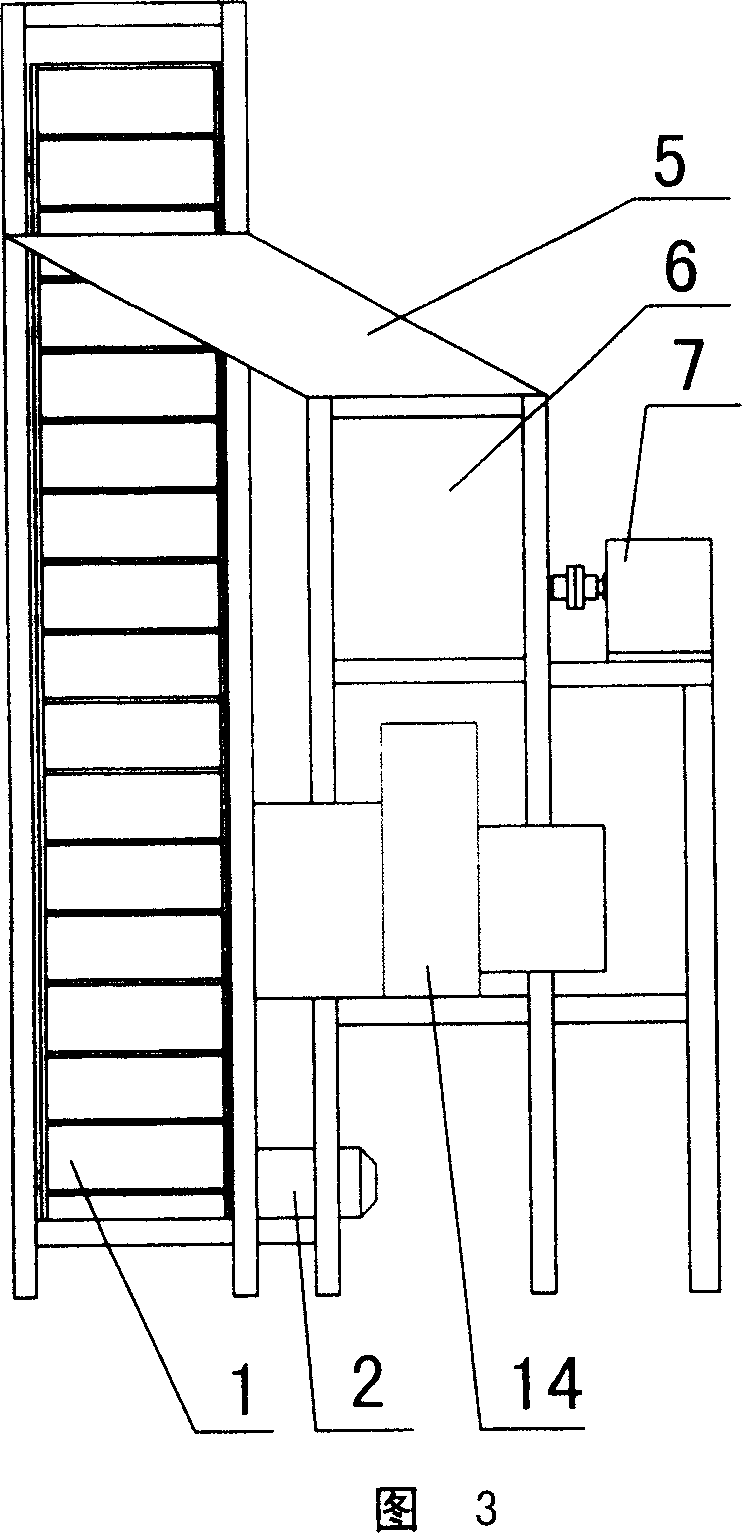

[0022] 1. Medium component conveyor belt 2, 4, 7, 18, 20, 29 motor 3, vibrating screen 5, feeding hopper 6, box 8, transmission shaft 9, crushing knife 10, scraper 11, spring support shaft 12, Overload protection spring 13, bracket 14, 33 fan 15, heavy component collector 16, medium component collector 17, light component conveyor belt 19, pool 21, horizontal shaft 22, material scooping plate 23, push plate with holes 24 , baffle plate 25, squeeze water hydraulic cylinder 26, baffle plate hydraulic cylinder 27, water return tank 28, box body 30, transmission shaft 31, loose teeth 32, comb plate 34, heavy component collector 35, plastic collector 36, bracket 37 , hydraulic power station

[0023]In the embodiment shown in Figures 1 to 4: the collected urban waste is first conveyed to the crusher by the medium component conveyor belt 1 with a partition, and the crusher feeding hopper 5 is under the output end of the medium component conveyor belt 1, The box body 6 of the crusher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com