Plastic waste efficient crushing and quick drying equipment

A high-efficiency crushing and fast-drying technology, which is applied in lighting and heating equipment, plastic recycling, drying gas arrangement, etc., can solve the problems of not being able to meet the demand, and the degree of plastic crushing treatment can not meet the expectation, so as to facilitate heat transfer and facilitate Full contact and prevent direct discharge from polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

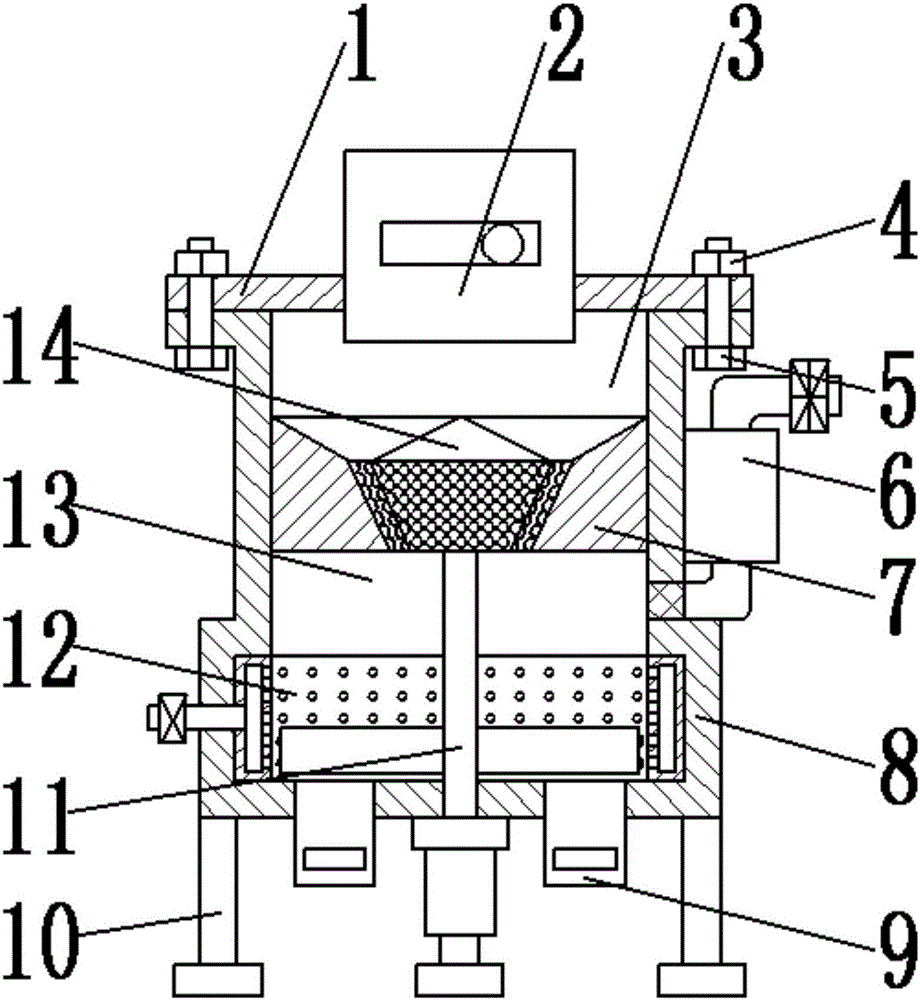

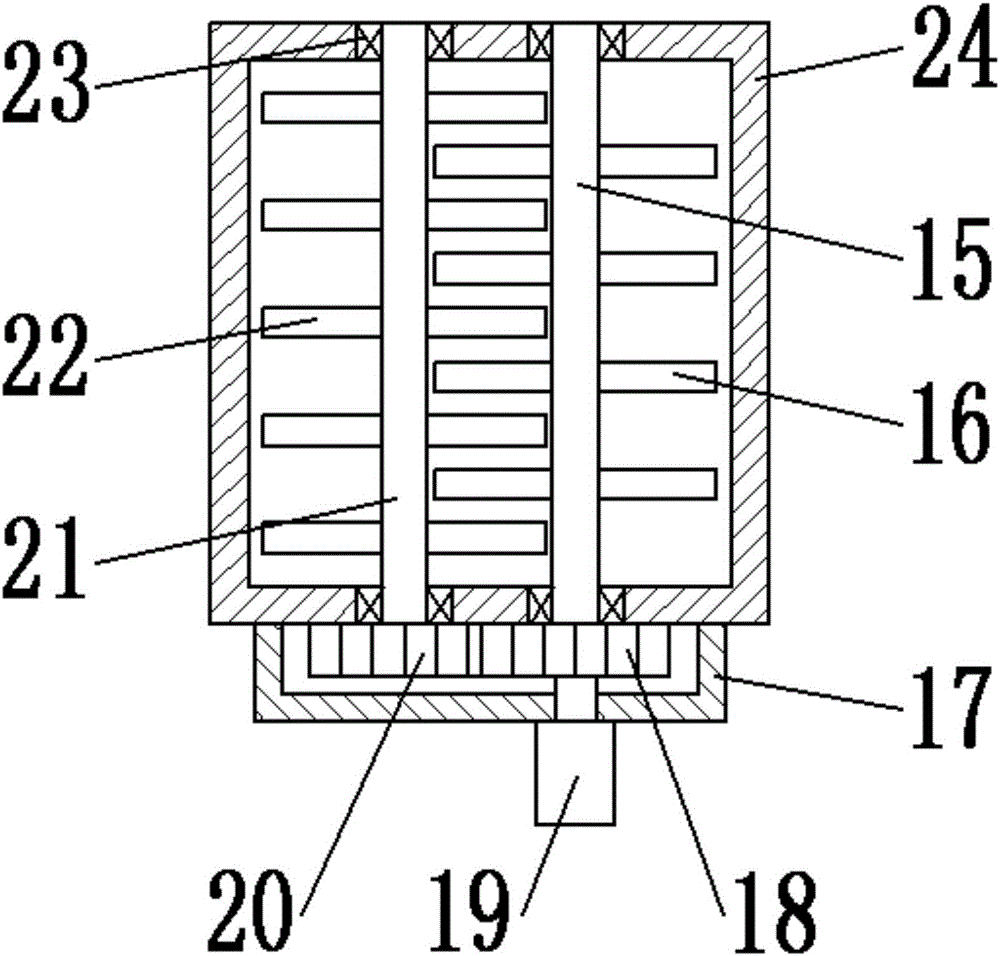

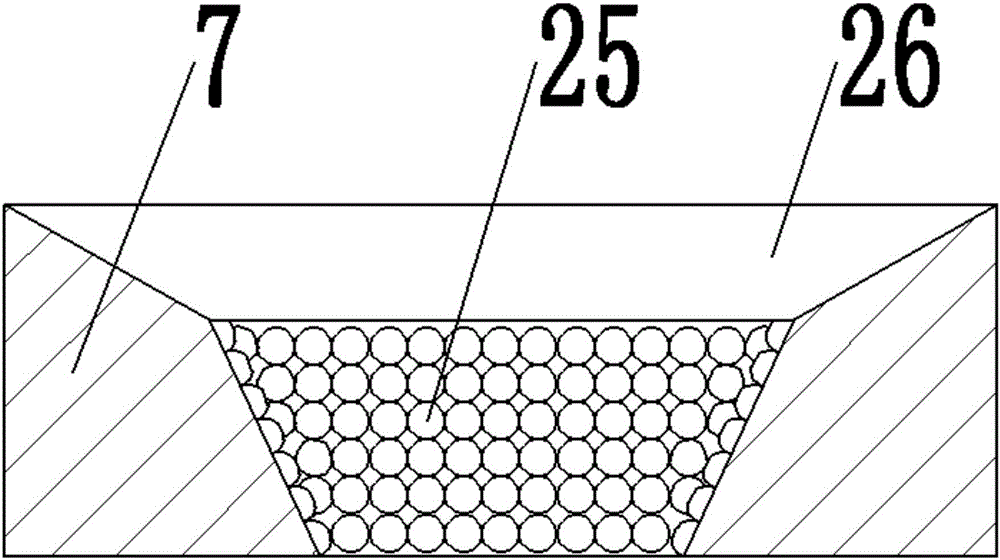

[0023] see Figure 1-7 , a high-efficiency crushing and rapid drying equipment for plastic waste, including a tank body 8; the tank body 8 is set as a hollow cylinder, and the interior is divided into a crushing chamber 3 and a drying chamber 13 by a fixed grinding disc 7, and an upper opening is provided at the top opening Cover 1; the upper cover 1 is fixedly connected with the tank body 8 through the mutual screwing of the bolt 5 and the nut 4, and the upper cover 1 and the tank body 8 are made of stainless steel; the upper cover 1 is fixed with a crushing device 2; The crushing device 2 is composed of a crushing tank 24 and a transmission box 17; the crushing tank 24 is arranged as a hollow cuboid, and the top surface and the bottom surface are connected; the transmission box 17 is fixed on the side wall of the crushing tank 24, and the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com