Method of preparing three-dimensional graphene glass composite

A composite material, graphene technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: the preparation of graphene glass

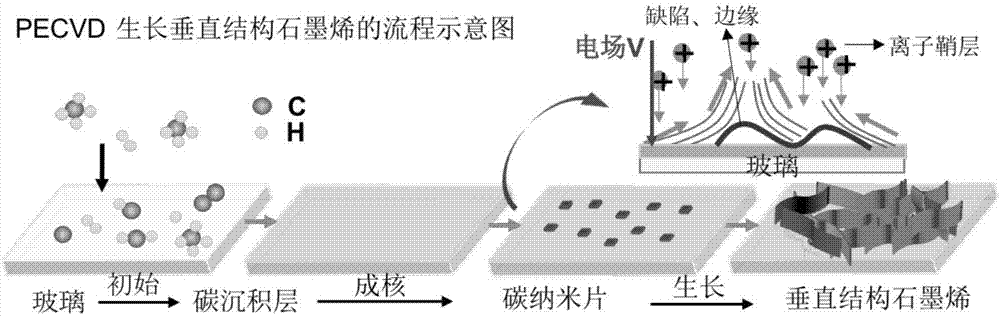

[0059] Put the cleaned 6-inch ordinary soda-lime glass on the reaction substrate, and use plasma-enhanced chemical vapor deposition technology to grow graphene glass with controllable transmittance and conductivity. figure 1 It is a schematic diagram of the process and principle of growing three-dimensional vertical structure graphene based on the PECVD system of the present invention. Concrete growth method comprises the following steps:

[0060] 1) Cleaning of ordinary soda-lime glass substrates:

[0061] Put a 10cmx10cm ordinary soda-lime glass substrate into ethanol, acetone, and isopropanol solutions for ultrasonic cleaning, and finally use deionized water for ultrasonic cleaning, and blow dry with nitrogen to obtain a clean glass substrate;

[0062] 2) Low temperature growth of graphene:

[0063] The growth method is based on the PECVD system, and utilizes direct current plasma enhanced chemical vapor deposition...

Embodiment 2

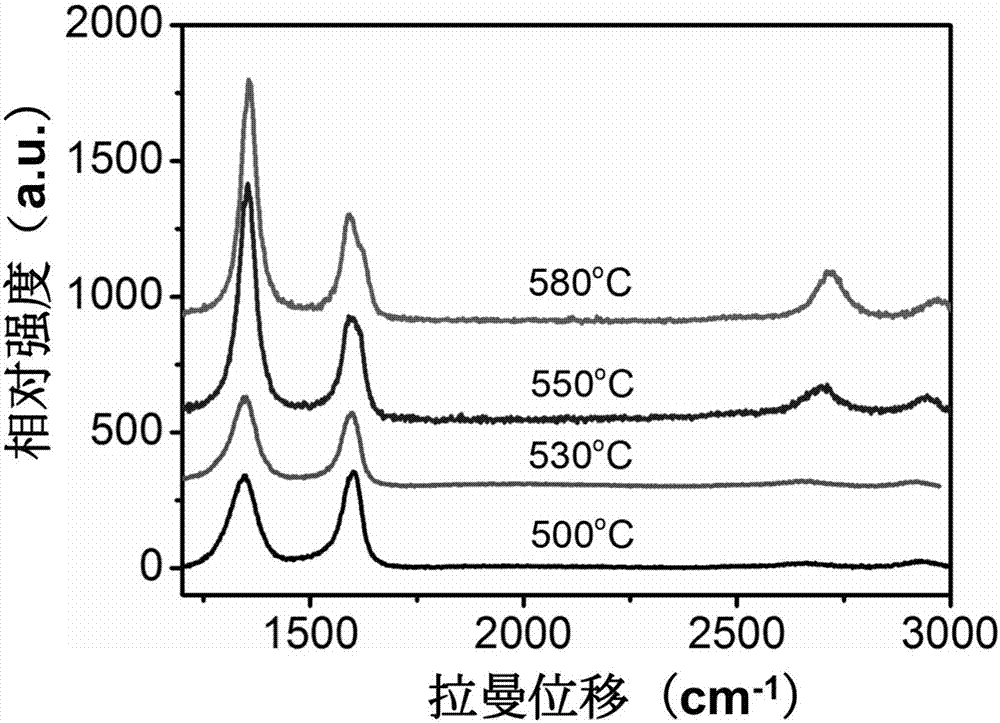

[0064] Example 2: Preparation of graphene glass under different growth temperatures below 600°C

[0065] The glass substrate used in the present invention is common soda-lime glass in people's daily life, which is an amorphous oxide mainly composed of silicon dioxide, calcium oxide and sodium oxide. It has poor thermal conductivity and cannot conduct electricity. The softening point of the glass is generally at Around 600°C. Most of the glass substrates currently reported use quartz glass and sapphire glass, and graphene is grown at a high temperature by chemical vapor deposition technology at 1000-1200 °C, and the growth time is often several hours, which greatly restricts the production cost. industrial application of graphene glass. At present, the present invention uses DC plasma enhanced chemical vapor deposition technology to generate high-energy electrons through DC high voltage. When the reaction gas is introduced into the chamber, the gas and electrons collide and io...

Embodiment 3

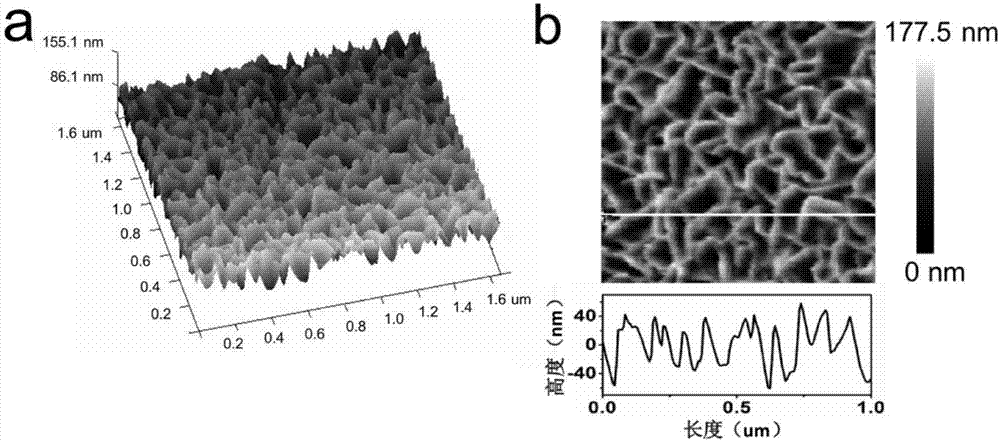

[0067] Example 3: Morphological changes of graphene on ordinary glass substrates controlled by growth time

[0068] During the growth process, the obtained graphene has a special three-dimensional structure due to the mutual modulation of electric field, interfacial energy, diffusion energy and other factors, and the structural characteristics are as follows: image 3 As shown, the graphene nanosheets are perpendicular to the growth substrate, the height is about tens of nanometers, the thickness is controllable from 1-10 layers, and the length varies from tens to hundreds of nanometers. The graphene nanosheets are stacked to form a network-like nanopore structure. . By adjusting the growth time of graphene, the vertical height of graphene can be continuously adjusted from 1 nm to 100 nm ( Figure 4), graphene glass samples with different transmittance and surface resistance can be obtained, and then the use of graphene glass to meet different needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com