Composite structural phosphorus fire retardant containing poly-DOPO cyclic phosphate and preparation method thereof

A technology of cyclic phosphate ester and composite structure, which is applied in the field of flame retardants, can solve the problems that affect the wide use, difficult to disperse uniformly, poor compatibility, etc., and achieve the effects of good flame retardant effect, convenient use, and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

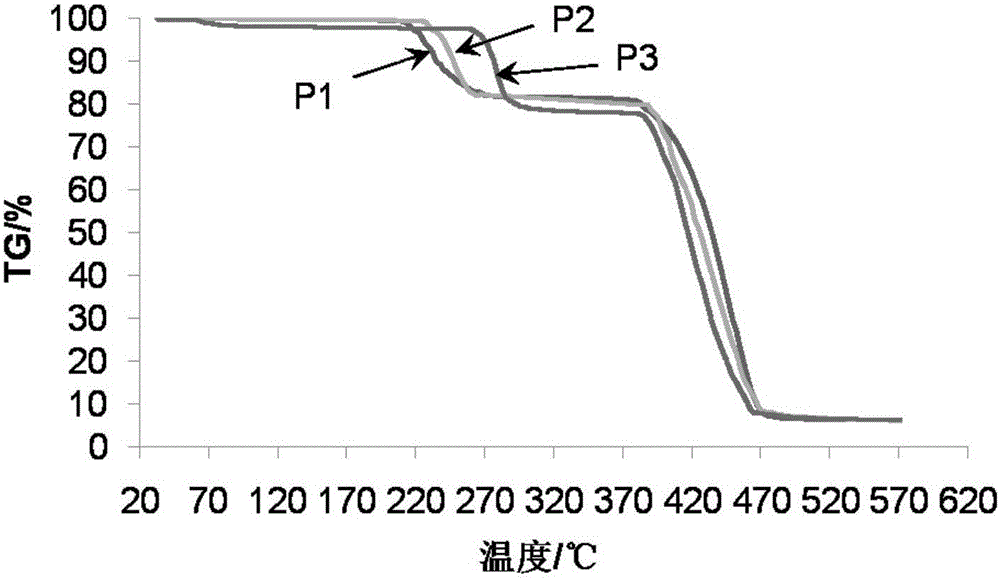

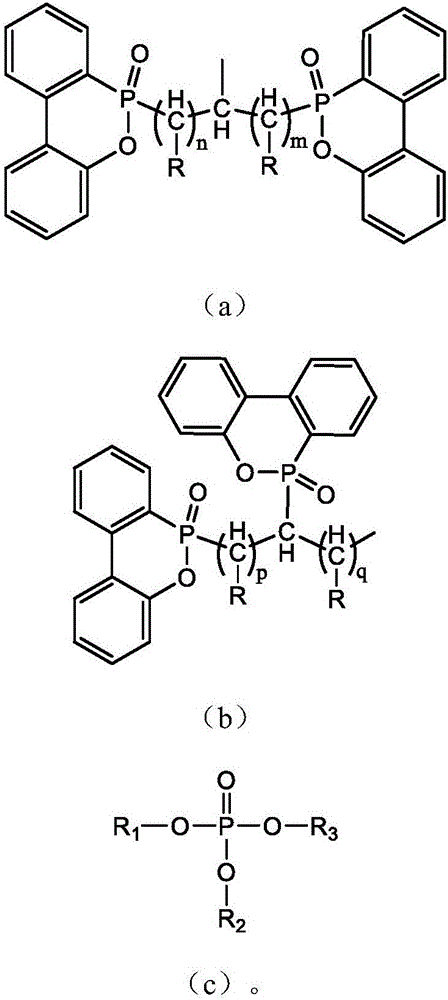

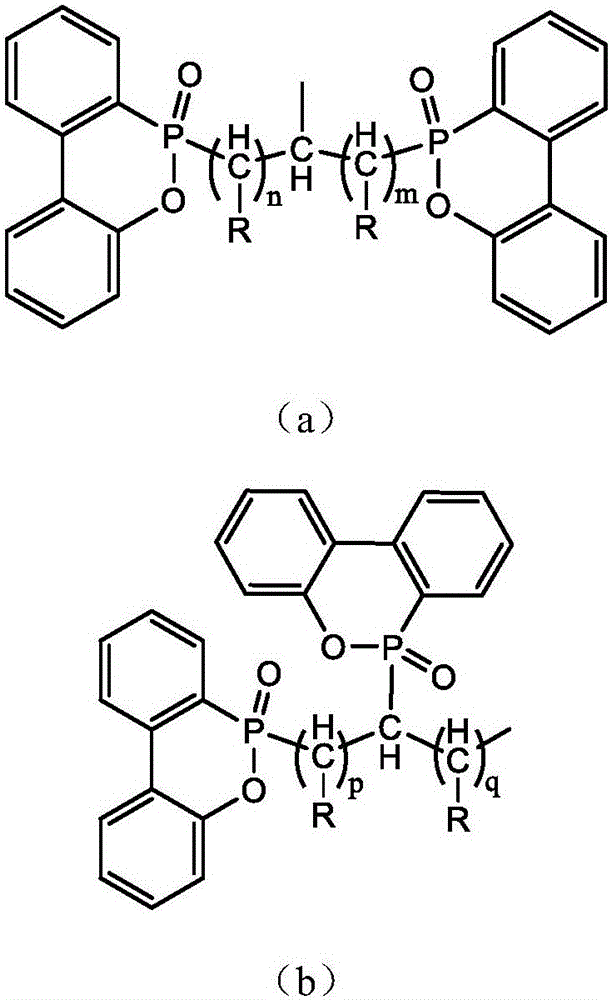

Embodiment 1

[0032]Install a mechanical stirrer, h-type oil-water separator and reflux condenser, dropping funnel and nitrogen inlet on a 3-liter four-necked flask. Add 253.3 grams (1.172mol) DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), 100.6 grams p-xylene, 800 grams PXE (1,1-bis (3,4-Dimethylphenyl)ethane) solvent and 56.45 g of glycerol solution (53.9 g (0.586 mol) of glycerol dissolved in 2.55 g of sodium iodide). After the oil-water separator was filled with p-xylene, the reaction mixture was heated to 200° C. for 14 hours under the protection of nitrogen flow, and the generated water was continuously discharged through the oil-water separator during the reaction. In the later stage of the reaction, less water is produced, so the reaction temperature is increased to 205° C. for another 2 hours. After the reaction, the temperature of the system was lowered to room temperature, and 29.94 grams (0.195 mol) of phosphorus oxychloride was added dropwise through the dropping f...

Embodiment 2

[0034] According to embodiment 1 program, only wherein reactant 56.45 gram glycerol solutions are changed into 64.67 gram butanetriol solutions (62.12 gram 1.2.4-butanetriol dissolves 2.55 gram sodium iodides), other reactant and solvent consumption are the same Change. And before the dropwise addition of phosphorus oxychloride after the reaction mixture was lowered to room temperature, 150 ml of pyridine was added to the reaction flask. The reaction product is light yellow syrupy liquid, marked as P2, the yield is about 81%, and the phosphorus content is 13.98%. 1H NMR: 7.13-7.95 ppm, m, 16H (H-Ar); 2.60-2.88-ppm, m, 6H (CH2); 3.54 ppm, m, 1H (CH). 13CNMR: 119.9-150.2ppm (C-Ar); 38.8-39.3ppm (CH2); 50.1ppm (CH). 31PNMR: 37.12-37.34ppm (mixture of chiral isomers of DOPO structure); -5.8ppm ((-O-)3P(O)).

Embodiment 3

[0036] 53.13 grams (0.391mol) of pentaerythritol were dissolved in 160 milliliters of ethanol, 2.55 grams of sodium iodide was added thereto, the mixture was heated to reflux for 2 hours, and then the ethanol was gradually distilled off to obtain a reaction mixture of pentaerythritol and sodium iodide. This mixture was used to replace the glycerol solution in Example 1 as a reactant, and the other reactants and solvents were used in the same amount, and the reaction was carried out according to the procedure in Example 1. And before the dropwise addition of phosphorus oxychloride after the reaction mixture was lowered to room temperature, 150 ml of pyridine was added to the reaction flask. The product is a white solid, marked as P3, with a yield of 86% and a phosphorus content of 13.84%. 1HNMR: 7.29-8.02ppm, m, 24H(H-Ar); 2.42ppm, s, 6H(P-CH2-C); 3.89ppm, s, 2H(C-CH2-O). 13CNMR: 119.9-150.2ppm (C-Ar); 39.7ppm (CH2); 69.0ppm (CH2), -4.8ppm (tert-C). 31PNMR: 37.12-37.34ppm (mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com