High-performance halogen-free flame-retardant long fiber reinforced polylactic acid composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of high-performance halogen-free flame-retardant long-fiber-reinforced polylactic acid composite materials and its preparation, can solve the problems of poor thermal stability and easy combustion of polylactic acid, and achieve good flame-retardant effect and low cost The effect of low cost and wide source of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

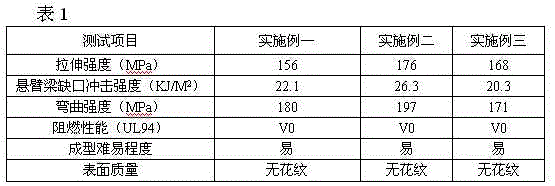

[0015] Example 1 of the present invention: high-performance halogen-free flame-retardant long-fiber reinforced polylactic acid composite material, calculated in parts by mass, including 86 parts of polylactic acid, 20 parts of toughening agent, 45 parts of fiber, 8 parts of compatibilizer, 1 part of chain extender, 1 part of antioxidant, 20 parts of halogen-free flame retardant, 4 parts of synergist, 15 parts of char-forming agent and 2 parts of dispersant; the toughening agent is TPU; the fiber is Glass fiber; described compatibilizer is the ternary random copolymer of styrene-acrylonitrile-glycidyl methacrylate; described halogen-free flame retardant is melamine polyphosphate; described synergist It is quaternary phosphate intercalated montmorillonite; the char-forming agent is pentaerythritol; the dispersant is pentaerythritol stearate;

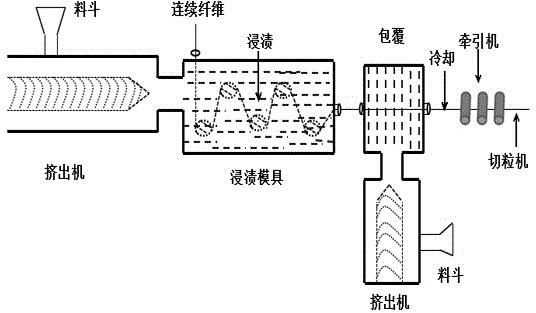

[0016] The preparation method of high-performance halogen-free flame-retardant long-fiber reinforced polylactic acid composite material i...

Embodiment 2

[0018] Example 2 of the present invention: high-performance halogen-free flame-retardant long fiber reinforced polylactic acid composite material, calculated in parts by mass, including 75 parts of polylactic acid, 25 parts of toughening agent, 50 parts of fiber, 10 parts of compatibilizer, 1.2 Parts of chain extender, 1.2 parts of antioxidant, 15 parts of halogen-free flame retardant, 5 parts of synergist, 12 parts of char-forming agent and 1 part of dispersant; described toughening agent is TPU; described fiber is Glass fiber; described compatibilizer is the ternary random copolymer of styrene-acrylonitrile-glycidyl methacrylate; described halogen-free flame retardant is melamine polyphosphate; described synergist It is quaternary phosphate intercalated montmorillonite; the char-forming agent is pentaerythritol; the dispersant is pentaerythritol stearate;

[0019] The preparation method of high-performance halogen-free flame-retardant long-fiber reinforced polylactic acid co...

Embodiment 3

[0021] Example 3 of the present invention: high-performance halogen-free flame-retardant long-fiber reinforced polylactic acid composite material, calculated in parts by mass, including 95 parts of polylactic acid, 15 parts of toughening agent, 40 parts of fiber, 6 parts of compatibilizer, 0.8 part of chain extender, 0.8 part of antioxidant, 25 parts of halogen-free flame retardant, 3 parts of synergist, 17 parts of char-forming agent and 3 parts of dispersant; described toughening agent is PBS; described fiber is Kenaf fiber; described compatibilizer is the ternary random copolymer of styrene-acrylonitrile-glycidyl methacrylate; described halogen-free flame retardant is melamine polyphosphate; described synergistic The agent is quaternary phosphate intercalated montmorillonite; the char-forming agent is pentaerythritol; the dispersant is pentaerythritol stearate;

[0022] The preparation method of high-performance halogen-free flame-retardant long-fiber reinforced polylactic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com