Method for preparing flexible biodegradable polytrimethylene carbonate composite film

A polypropylene carbonate and composite film technology, applied in the field of composite films and their preparation, can solve problems such as limiting the practical application of composite materials, achieve good film blowing stability, good mechanical properties, and improve brittleness and low-temperature viscous flow problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

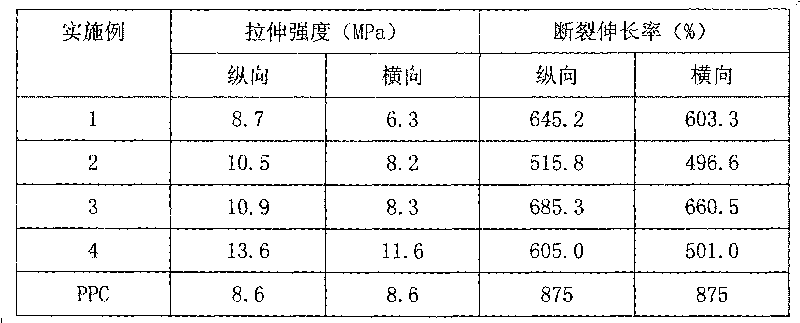

Examples

Embodiment 1

[0051] Take each component by the following parts by weight:

[0052] PPC60

[0053] TPU40

[0054] Diisocyanate 0.2

[0055] Antioxidant 1010 0.3

[0056]Nano silica 1

[0057] Triphenyl phosphite 0.2

[0058] Erucamide 1

[0059] Nano calcium carbonate 5

[0060] Oxalic acid 0.5

[0061] Benzoin monoalkyl ether 0.2

[0062] The preparation process is as follows:

[0063] The raw materials were dried in an oven at 45°C for 6 hours, then mixed in a high-speed mixer for 0.5-1 minute at high speed, and then entered into an internal mixer at a temperature of 135°C for blending and granulation.

[0064] Then use the pellets for blow molding into film, the processing technology is as follows: Extrude by plastic melting extruder for blow molding

[0065] Extruder aspect ratio: 40:1

[0066] The temperature settings are as follows:

[0067] Zone 1: 105°C

[0068] Zone 2: 130°C

[0069] Zone 3: 145°C

[0070] Die head: 140°C

[0071] The material is fed from the hopper...

Embodiment 2

[0080] Take each component by the following parts by weight:

[0081] PPC 70

[0082] TPU 30

[0083] Diisocyanate 0.2

[0084] Antioxidant 1010 0.3

[0086] Triphenyl phosphite 0.2

[0087] Erucamide 1

[0088] Nano calcium carbonate 3

[0089] Oxalic acid 0.5

[0090] Benzoin monoalkyl ether 0.2

[0091] The preparation process is as follows:

[0092] The raw materials were dried in an oven at 45°C for 6 hours, then mixed in a high-speed mixer for 0.5-1 minute at high speed, and then entered into a twin-screw extruder at 135°C for extrusion and granulation.

[0093] Then use the pellets for blow molding into film, the processing technology is as follows: Extrude by plastic melting extruder for blow molding

[0094] Extruder aspect ratio: 40:1

[0095] The temperature settings are as follows:

[0096] Zone 1: 105°C

[0097] Zone 2: 140°C

[0098] Zone 3: 145°C

[0099] Die head: 140°C

[0100] The material is fed from the hopper, and th...

Embodiment 3

[0109] Take each component by the following parts by weight:

[0110] PPC 80

[0111] TPU 20

[0112] Diisocyanate 0.1

[0113] Antioxidant 1010 0.3

[0114] Montmorillonite 1

[0115] Triphenyl phosphite 0.2

[0116] Erucamide 1

[0117] Nano calcium carbonate 5

[0118] Oxalic acid 0.5

[0119] Benzoin monoalkyl ether 0.2

[0120] The preparation process is as follows:

[0121] The raw materials were dried in an oven at 45°C for 6 hours, then mixed in a high-speed mixer for 0.5-1 minute at high speed, and then entered into a twin-screw extruder at 130°C for extrusion and granulation.

[0122] Then use the pellets for blow molding into film, the processing technology is as follows: Extrude by plastic melting extruder for blow molding

[0123] Extruder aspect ratio: 40:1

[0124] The temperature settings are as follows:

[0125] Zone 1: 105°C

[0126] Zone 2: 130°C

[0127] Zone 3: 145°C

[0128] Die head: 150°C

[0129] The material is fed from the hopper, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com