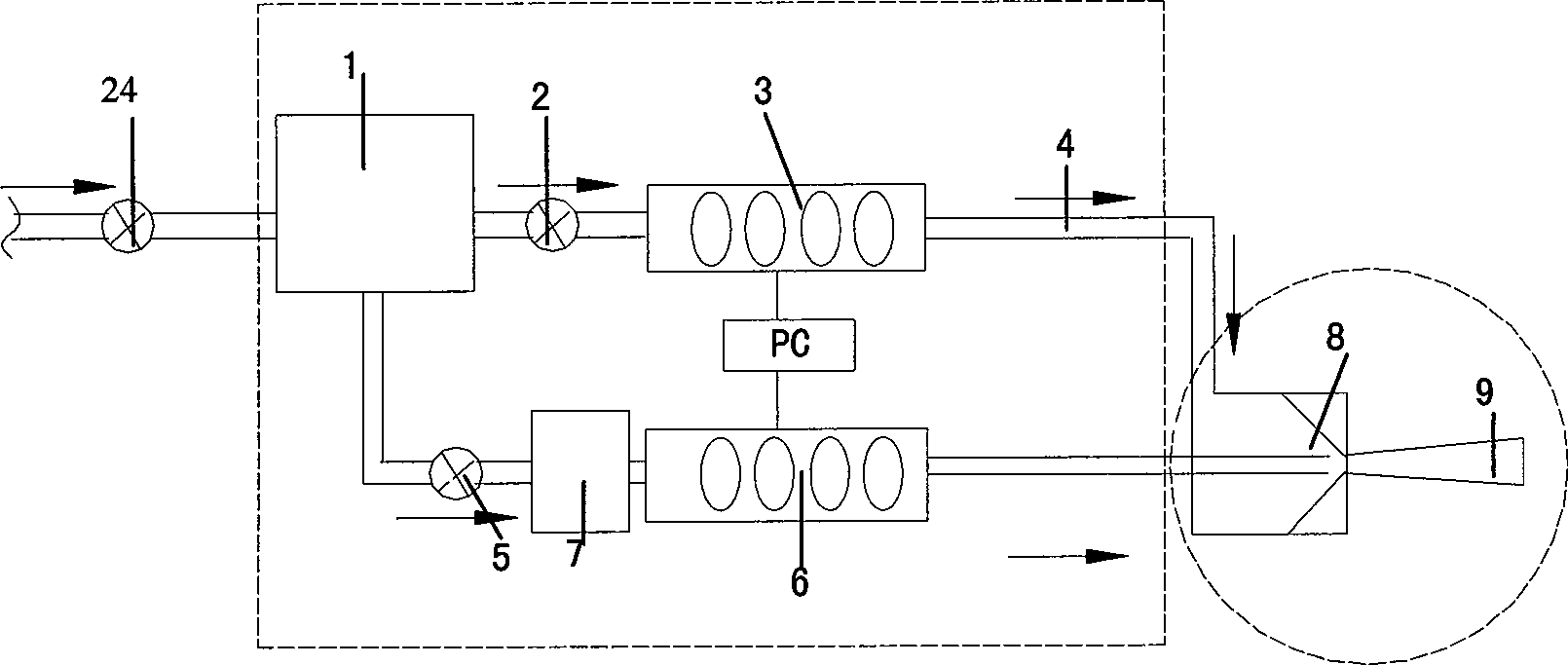

Portable cold-air dynamic spraying device

A technology of power spraying and cold gas, which is applied in the direction of surface coating liquid device, coating, heating inorganic powder coating, etc., which can solve the problems of waste of resources, waste of raw materials and environment, increase of process cost, etc., and achieve reduction of carrier gas The effects of reducing pressure, reducing preparation costs, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

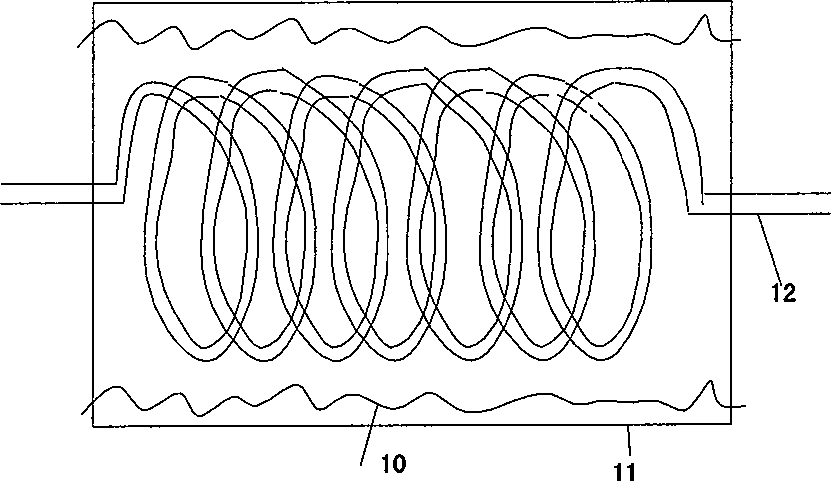

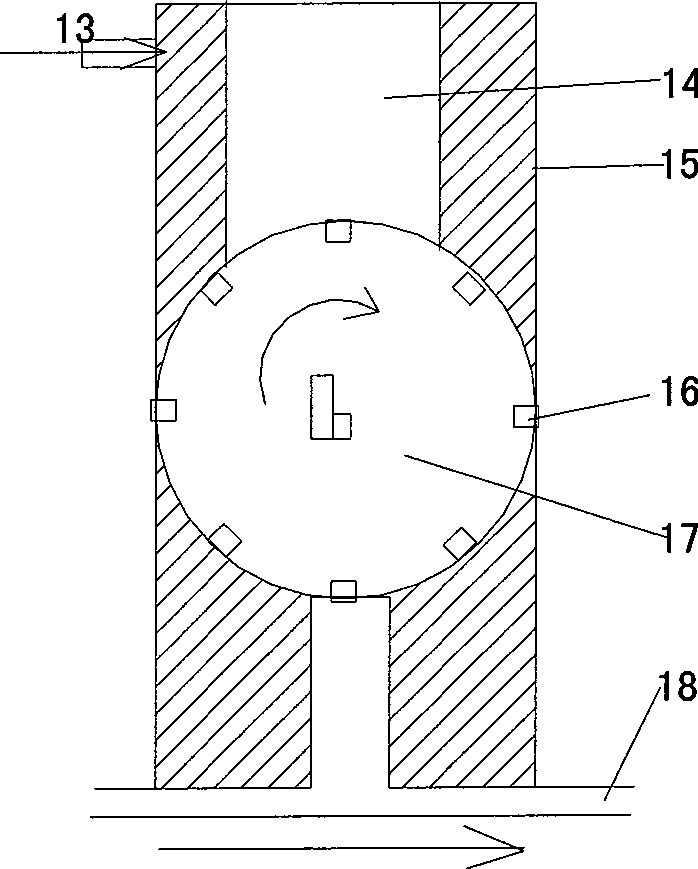

Method used

Image

Examples

Embodiment 1

[0022] The base material is Q235 steel, the surface is treated by sandblasting and degreasing, and the sandblasting treatment is 15 minutes; the powder is pure aluminum prepared by ion atomization method, sieved through a standard sieve of 300 mesh to 500 mesh, and dried at 120°C for 30 minutes before use ; Spraying process parameters are: carrier gas type, N2; carrier gas inlet pressure, 0.8MPa; carrier gas temperature, 240°C; spraying distance, 25mm, powder temperature, 200°C. The scanning rate is 20mm / s; the number of scanning channels is 4.

[0023] It is found that the deposition rate of aluminum powder is >90%, the porosity of the side metallographic observation is <2%, the oxygen content is <2%, the bonding force between the coating and the substrate is 8.3MPa, and the thickness of the coating deposited by 4 passes is About 1mm.

Embodiment 2

[0025] The base material is Q235 steel, the surface is treated by sandblasting and degreasing, and the sandblasting treatment is 15 minutes; the powder is a mixture of pure aluminum and pure zinc powder prepared by ion atomization method, the content ratio of zinc and aluminum in the powder is 85:15, and it is passed through 300 mesh ~800 mesh standard sieve, dry at 120°C for 30 minutes before use; spraying process parameters are: carrier gas type, N2; carrier gas inlet pressure, 0.8MPa; carrier gas temperature, 240°C; spraying distance, 25mm, powder Temperature, 200°C. The scanning rate is 20mm / s; the number of scanning channels is 2.

[0026] It was found by measurement that the deposition rate of the mixed powder was >85%, the lost powder was mainly zinc powder, the porosity of the obtained side metallographic observation was <2%, the oxygen content was <2%, and the bonding force between the coating and the substrate was 10MPa, the coating thickness deposited by 2 layers i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com