Aluminium alloy sheet mould pressing quenching composite molding method and integrated device thereof

A technology of composite forming of aluminum alloy sheets, applied in the direction of quenching devices, forming tools, metal processing equipment, etc., can solve the problems of not being suitable for large-scale industrial production of aluminum alloy sheets, reducing the precision of parts, and poor formability, etc., to meet the requirements of large-scale industrialization Batch automated production, avoiding deformation and springback, and good dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

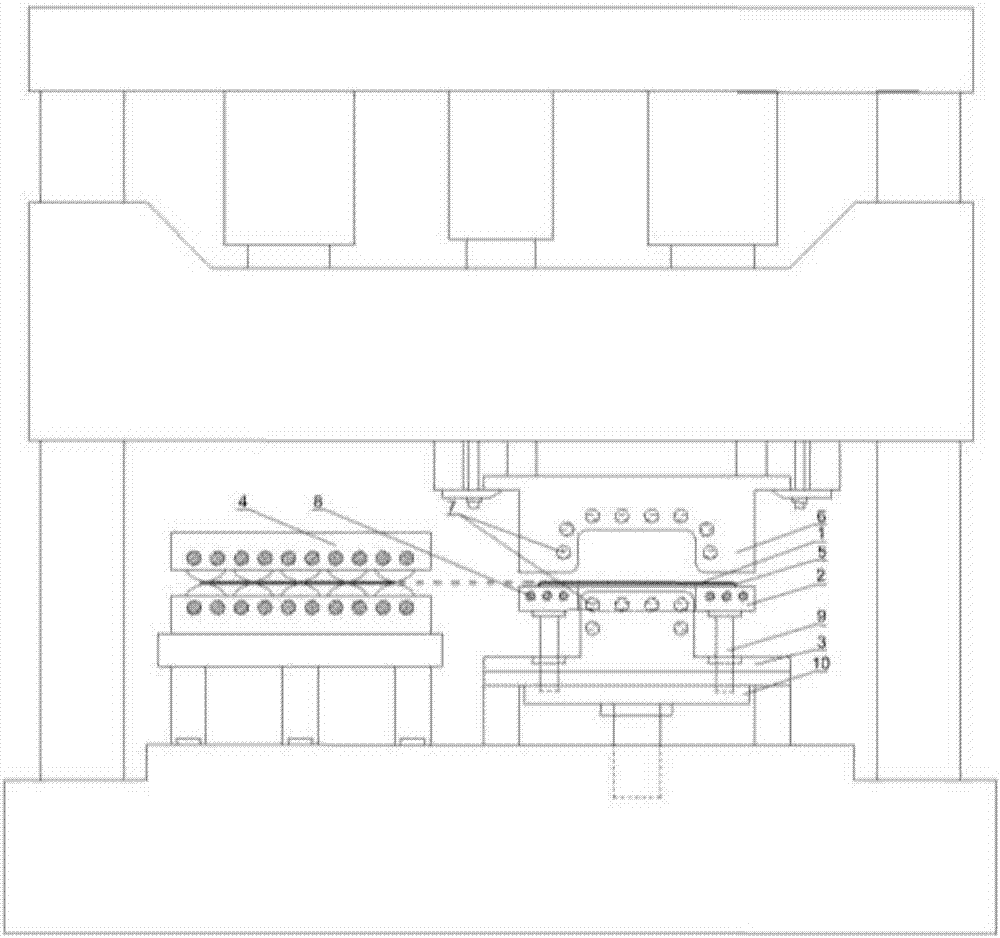

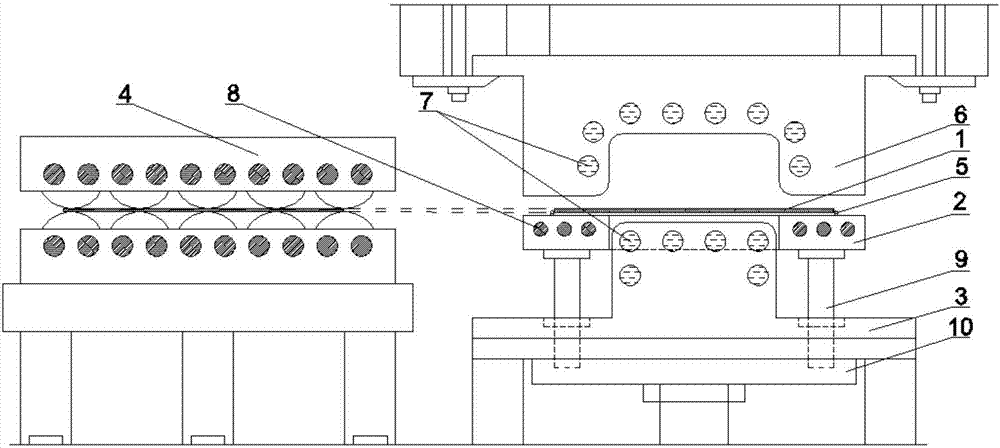

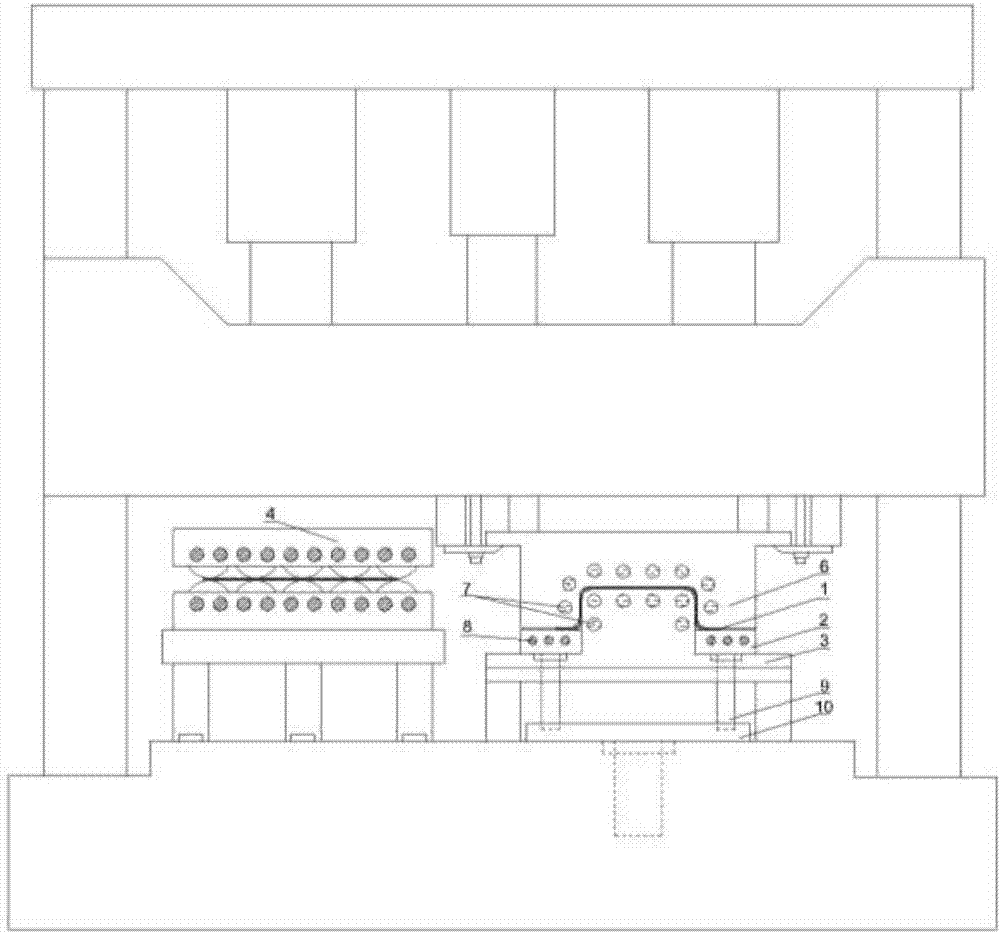

[0040] In this example, see Figure 1~4 , an aluminum alloy heat treatment and thermoforming integrated device, including a heating furnace 4 and a thermoforming device, which are sequentially connected to form front and rear process equipment, and the heating furnace 4 can perform solution heat treatment on the aluminum alloy plate 1 before forming;

[0041] The thermoforming device is composed of a flip-chip molding mold driven by a hydraulic press, mainly composed of a die 6, a punch 3, a flat blank holder 2, a hydraulic press base 10, and a hydraulic dowel 9, and the die 6 is fixed on the hydraulic press. On the middle sill, the high-temperature hot-state aluminum alloy plate 1 obtained after solution heat treatment in the heating furnace 4 is transferred to the flat blank holder 2 by the conveying device for positioning and fixing, and the die 6 is hydraulically driven to clamp downward and upward The mold is opened, and the aluminum alloy plate 1 is subjected to pressure...

Embodiment 2

[0059]This embodiment is basically the same as Embodiment 1, especially in that:

[0060] Hydraulic dowel rod 9 can also rely on its own weight to fall back. The single-action hydraulic cylinder of the device in this embodiment works under force in one direction, and the hydraulic dowel 9 as a plunger returns by its own weight, which can ensure the working stability of the hydraulic system and reduce the occurrence of hard interference in the force transmission system , reduce the failure rate of the hydraulic system, improve the service life of the equipment, and better guarantee the stability of the composite molding process of aluminum alloy sheet molding and quenching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com