Lens-forming silicone resin composition and silicone lens

a technology of silicone resin and composition, which is applied in the field of silicone resin composition, can solve the problems of short heat resistance and discoloration resistance of thermoplastic resin, the lens of prior art thermoplastic resin cannot be used, and the molding time of silicone resin which is thermosetting resin is long compared with prior art thermoplastic resin, so as to reduce the molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

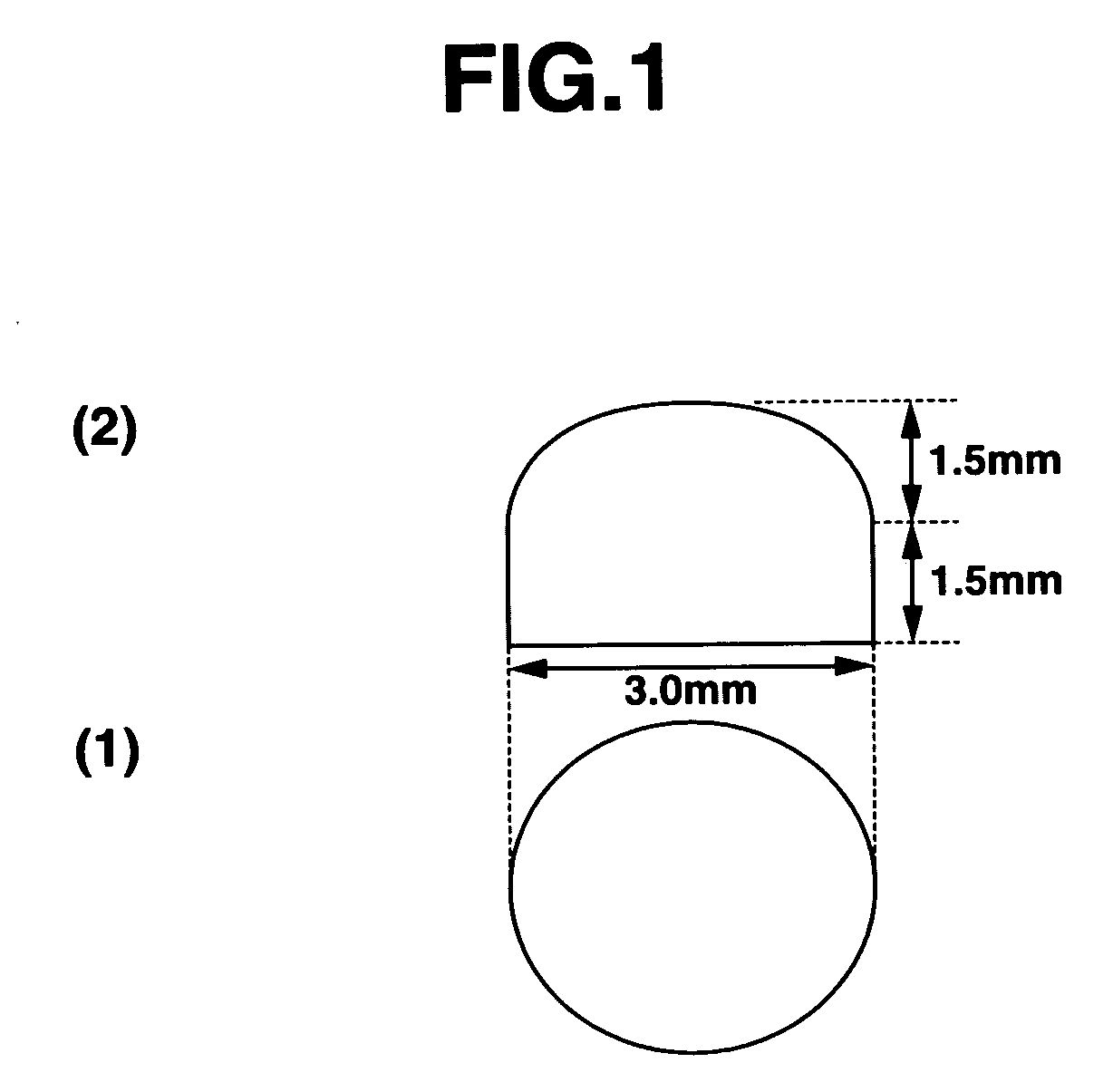

Image

Examples

reference example 1

[0046] With vigorous stirring, a mixture of 698 parts of phenyltrichlorosilane, 169 parts of methylvinyldichlorosilane, 194 parts of dimethyldichlorosilane and 530 parts of toluene was added dropwise to 2,500 parts of water over 60 minutes. Stirring was continued for a further 60 minutes, after which the toluene solution was washed with water until neutral. After water washing, the toluene solution was adjusted to a siloxane concentration of 25%. 0.42 part of potassium hydroxide was added to the toluene solution which was heated under reflux for 5 hours for polymerization. Then 13.8 parts of trimethylchlorosilane was added to the solution, followed by stirring for 60 minutes at room temperature, neutralization of the alkali, and removal of residual silanol groups. This was filtered and heated under vacuum for distilling off the toluene, leaving a transparent vinyl-bearing organopolysiloxane.

example 1

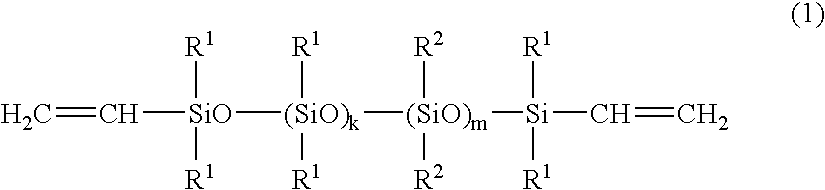

[0047] To 50 parts of a polysiloxane (VF) having the formula (i) were added 50 parts of a vinylmethylsiloxane (VMQ) of resin structure consisting of 50 mol % SiO2 units, 42.5 mol % (CH3)3SiO0.5 units and 7.5 mol % Vi3SiO0.5 units, an amount to give a 1.5-fold molar amount of SiH groups relative to the total of vinyl groups in the VF and VMQ components of an organohydrogenpolysiloxane having the formula (ii) and 0.05 part of an octyl alcohol-modified chloroplatinic acid solution. By thoroughly mixing the ingredients, a silicone resin composition was prepared.

example 2

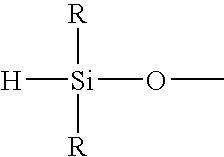

[0048] A silicone resin composition was prepared by mixing 100 parts of the vinyl-bearing organopolysiloxane obtained in Reference Example 1 with 30 parts of an organohydrogenpolysiloxane having the following formula and 0.05 part of a 1% octyl alcohol-modified chloroplatinic acid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com