Grade-A fireproof self-heat-insulation wall body and manufacturing method thereof

A manufacturing method and self-insulation technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as failure to achieve energy saving, prolong construction period, increase cost, etc., reduce bulk density and reduce labor intensity , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

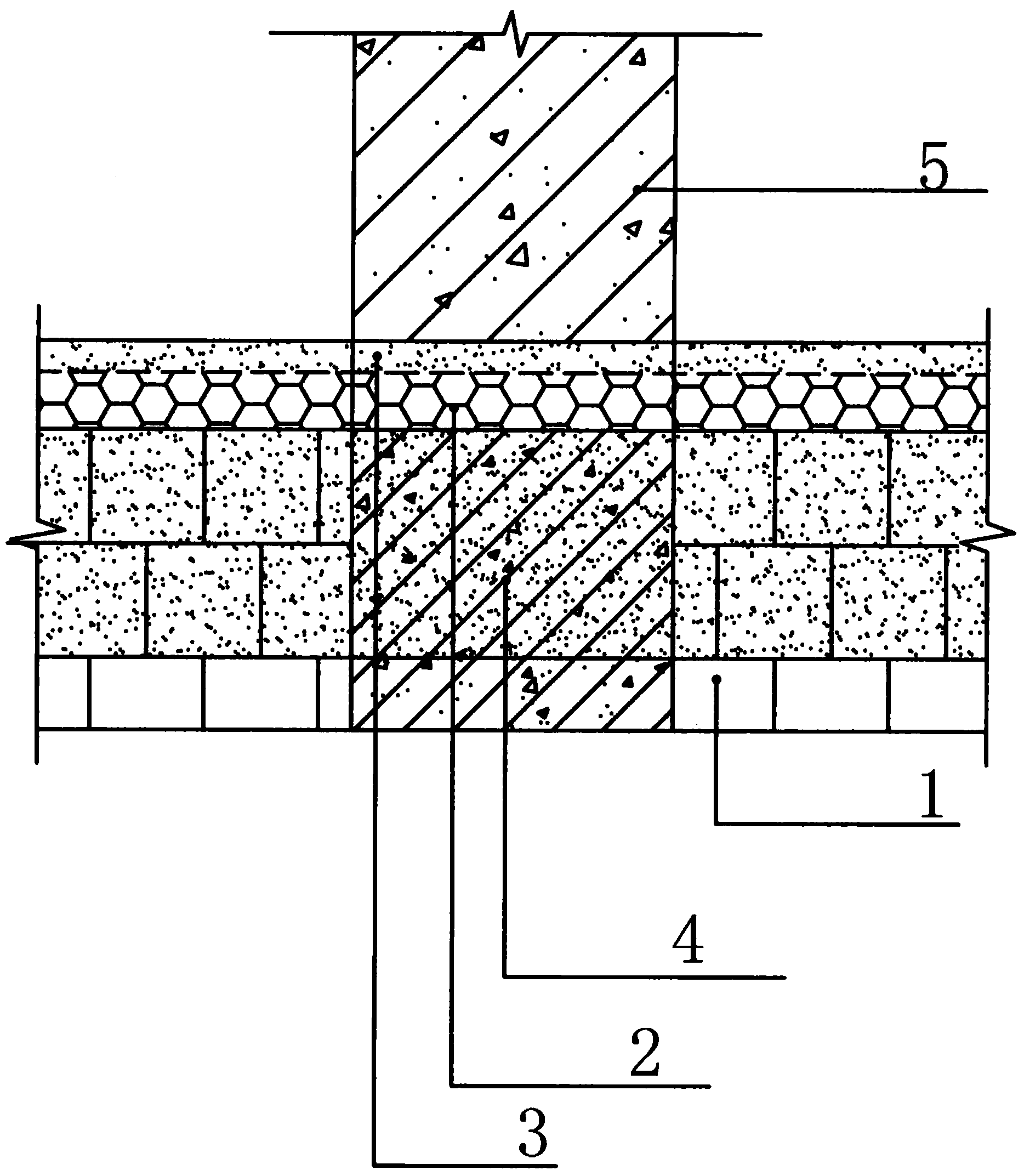

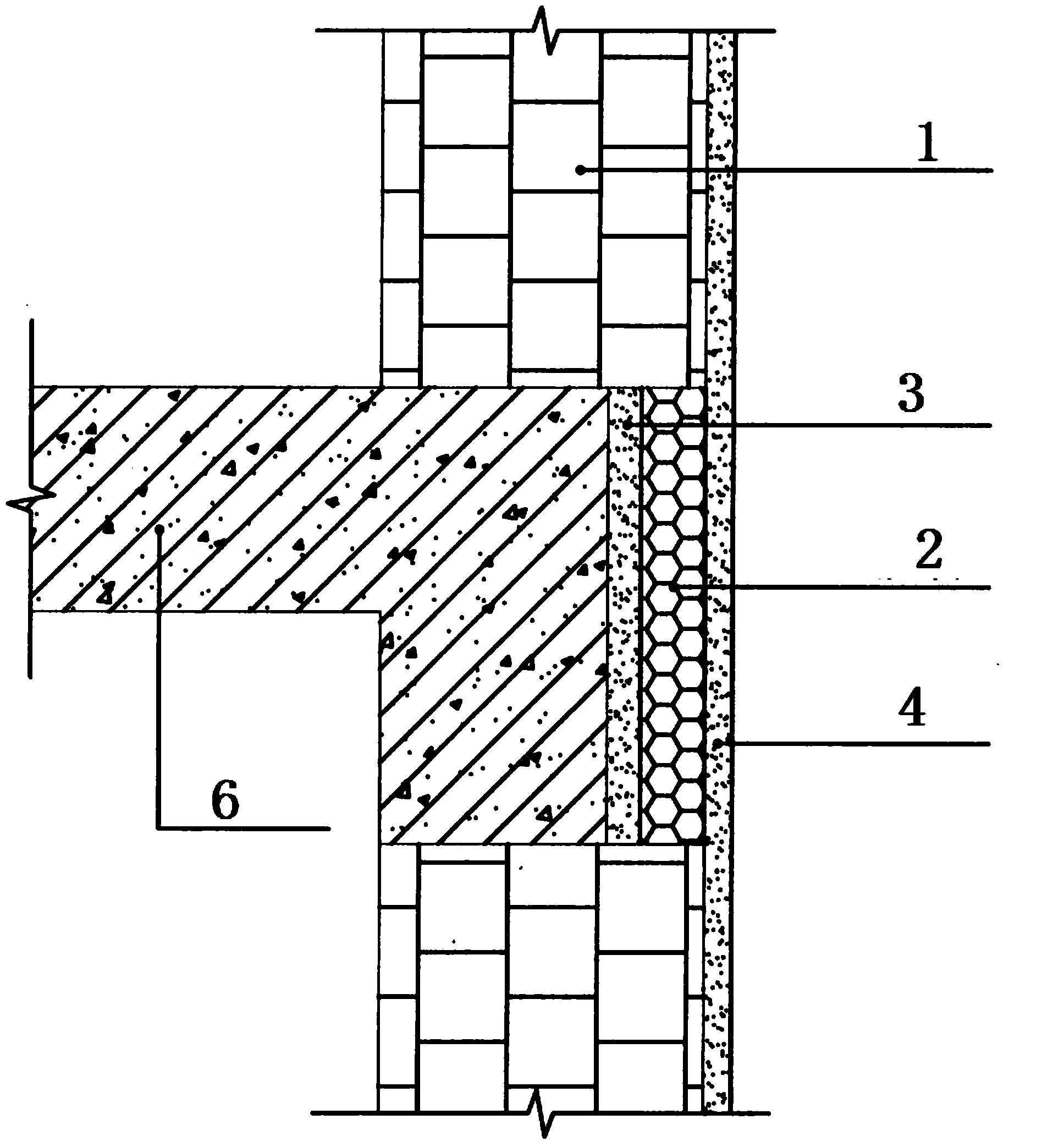

[0045] Such as figure 1 , figure 2 As shown, a class A fireproof self-insulation wall, including self-insulation wall blocks, HX insulation boards, plastic rivets, masonry mortar layer and thermal insulation anti-cracking mortar layer; wherein, self-insulation wall blocks are installed in Pre-cast on the frame structure of the building with reinforced cement on site; the HX insulation board is bonded to the beams and columns of the frame structure through the masonry mortar layer, and fixed by plastic rivets; the HX insulation board and self-insulation wall blocks Each side of the composition with the masonry mortar layer is wrapped by thermal insulation and anti-cracking mortar; the above-mentioned self-insulation wall block, HX insulation board, plastic rivet bolt, masonry mortar layer and thermal insulation and anti-cracking mortar layer are integrated into one structure to form A Grade fire self-insulation wall.

[0046] Self-insulating wall blocks are composed of the f...

Embodiment 2

[0060] A class A fireproof self-insulation wall, including self-insulation wall blocks, insulation boards, plastic rivets, masonry mortar layer and thermal insulation and anti-cracking mortar layer; On-site cast-in-place frame structure buildings; the insulation board is bonded to the beams and columns of the frame structure through the masonry mortar layer, and fixed by plastic rivets; the insulation board, self-insulation wall blocks and the masonry mortar layer All sides of the composition are wrapped by thermal insulation and anti-cracking mortar; the above-mentioned self-insulation wall blocks, insulation boards, plastic rivets, masonry mortar layer and insulation and anti-cracking mortar layer are integrated to form a class A fire-proof self-insulation wall.

[0061] Self-insulating wall blocks are composed of materials with the following weight ratio: No. 42.5 ordinary Portland cement 50kg, quartz sand 30kg, grade 1 fly ash 10kg, calcium oxide powder 15kg, rapid hardenin...

Embodiment 3

[0075] A class A fireproof self-insulation wall, including HX self-insulation wall blocks, HX insulation boards, plastic rivets, masonry mortar layer and thermal insulation anti-cracking mortar layer; wherein, the HX self-insulation wall blocks are installed in the pre- On the frame structure of the building formed by reinforced cement on-site pouring; HX insulation board is bonded to the beams and columns of the frame structure through the masonry mortar layer, and fixed by plastic rivets; HX insulation board, HX self-insulation wall block Each side of the composition with the masonry mortar layer is wrapped by thermal insulation and anti-cracking mortar; the above-mentioned HX self-insulation wall block, HX insulation board, plastic rivet bolts, masonry mortar layer and thermal insulation and anti-cracking mortar layer are integrated into one structure, forming Class A fireproof self-insulation wall.

[0076] HX self-insulating wall blocks are composed of the following weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com