Connected paper box forming machine

A forming machine and carton technology, applied in carton/carton manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of rising labor costs and low profit margins of shoe box processing enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described below in conjunction with the accompanying drawings of the description.

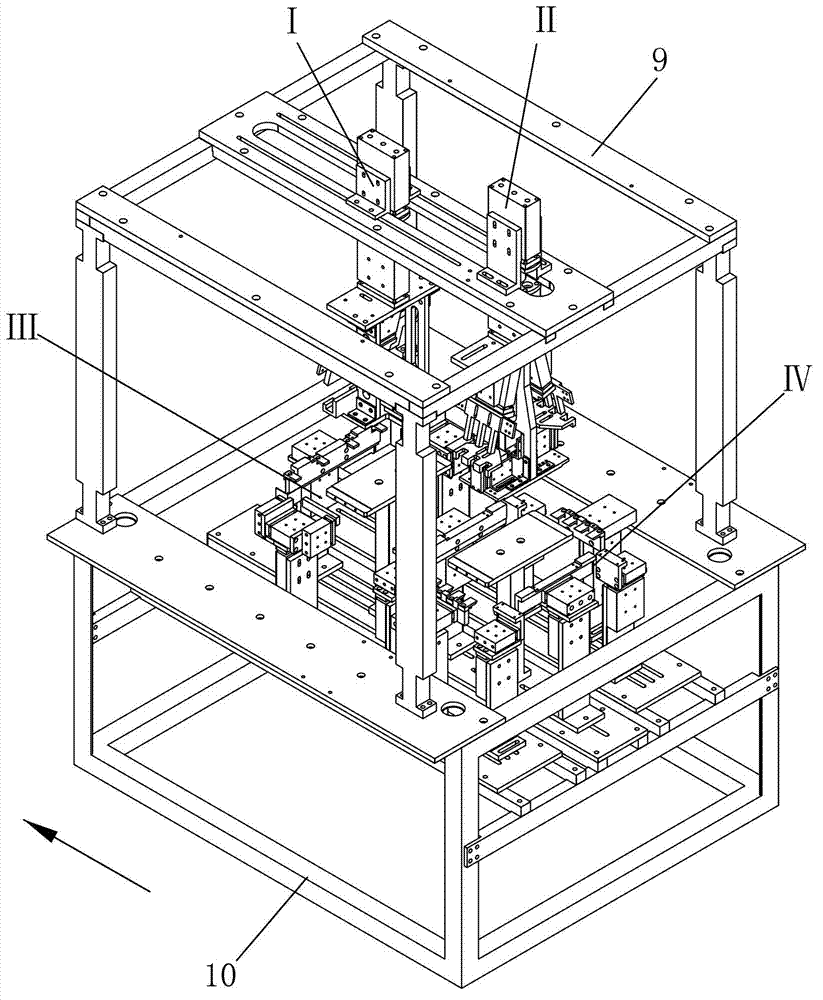

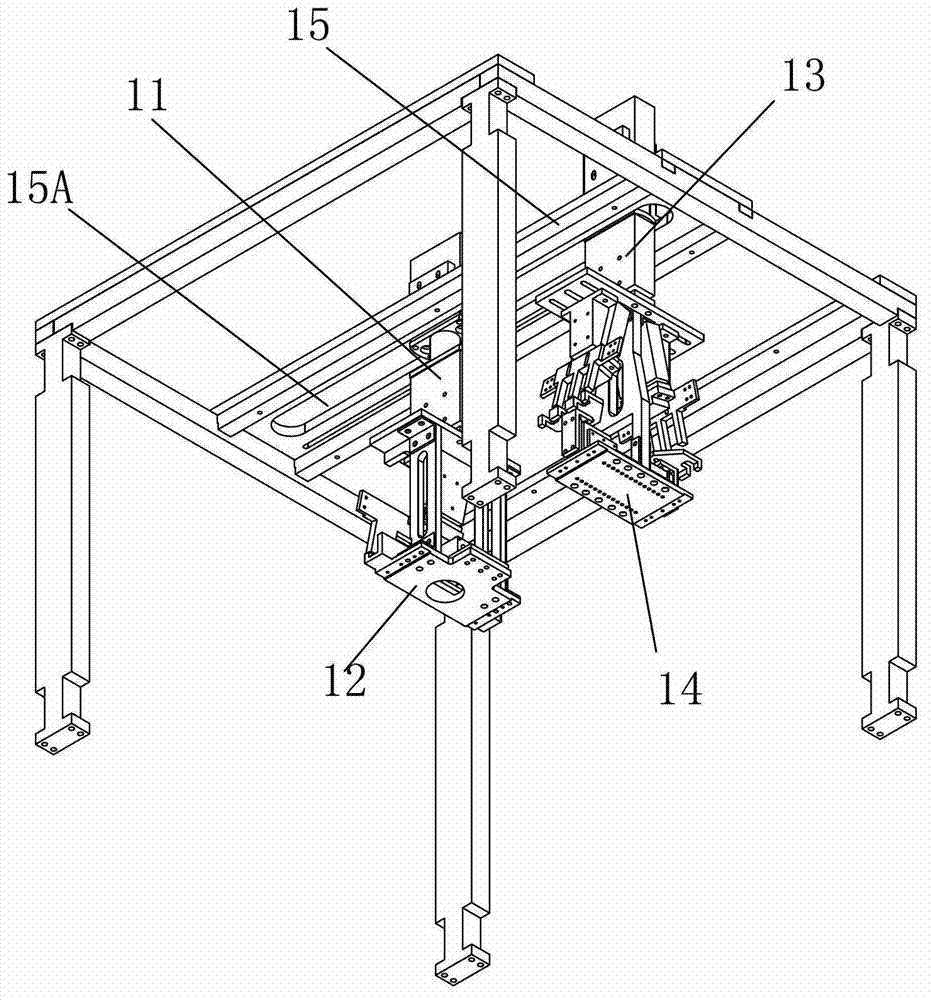

[0092] Such as figure 2 As shown, the one-piece carton forming machine of the present invention includes the No. 1 station for folding the box cover and the No. 2 station for folding the box body on the frame; the No. 1 station consists of The No. 1 master cylinder device I installed on the upper frame 9 and the No. 1 hemming device III installed on the lower frame 10 are composed. The No. 1 master cylinder device corresponds to the upper and lower positions of the No. 1 hemming device; It consists of No. 2 master cylinder device II on the upper frame and No. 2 hemming device IV installed on the lower frame. The No. 2 master cylinder device corresponds to the upper and lower positions of No. 2 hemming device. In order to ensure the accuracy of origami operation, the No. 1 master cylinder device and the No. 2 master cylinder device are distributed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com