Separating drying device for fodder machining production

A feed processing and drying device technology, applied in drying, feed, dryer and other directions, can solve the problems of limited processing efficiency, excessive feed moisture loss, incomplete feed drying, etc., and achieve the effect of improving baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

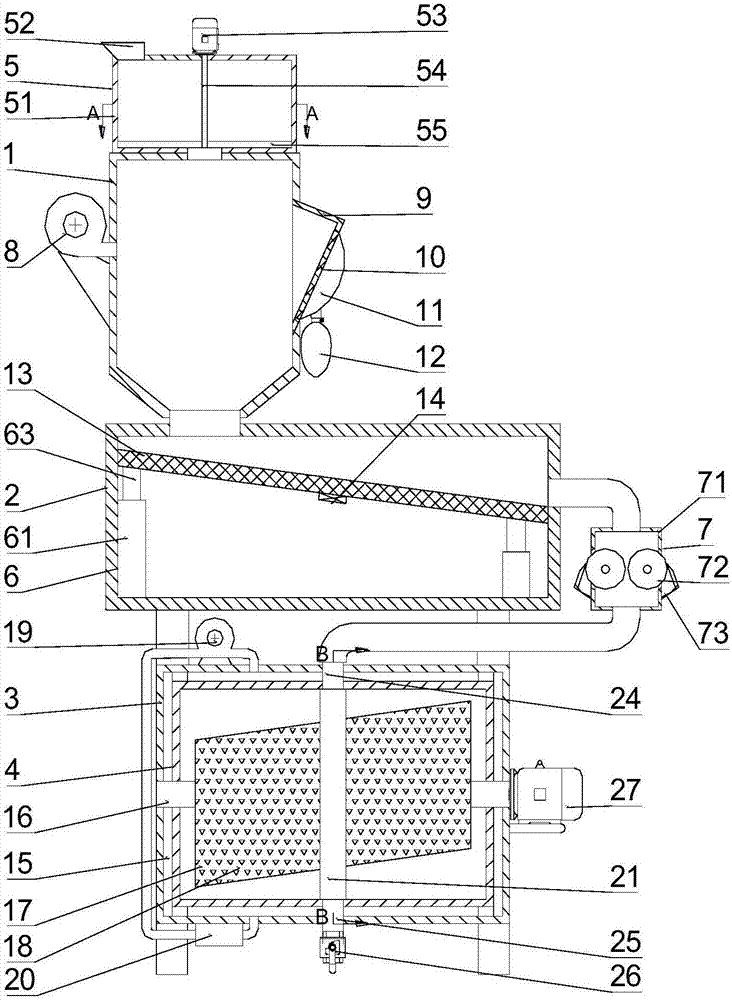

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

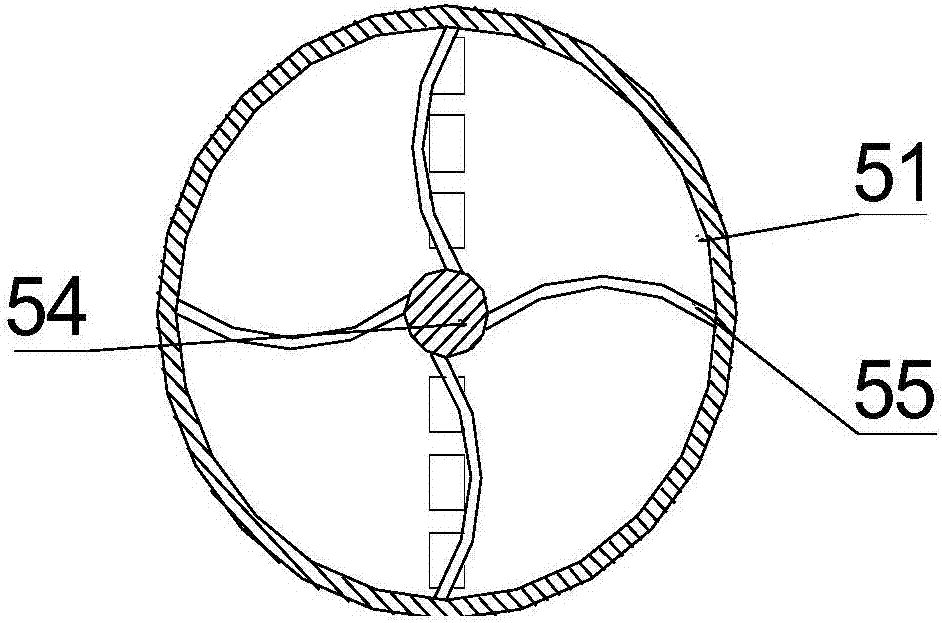

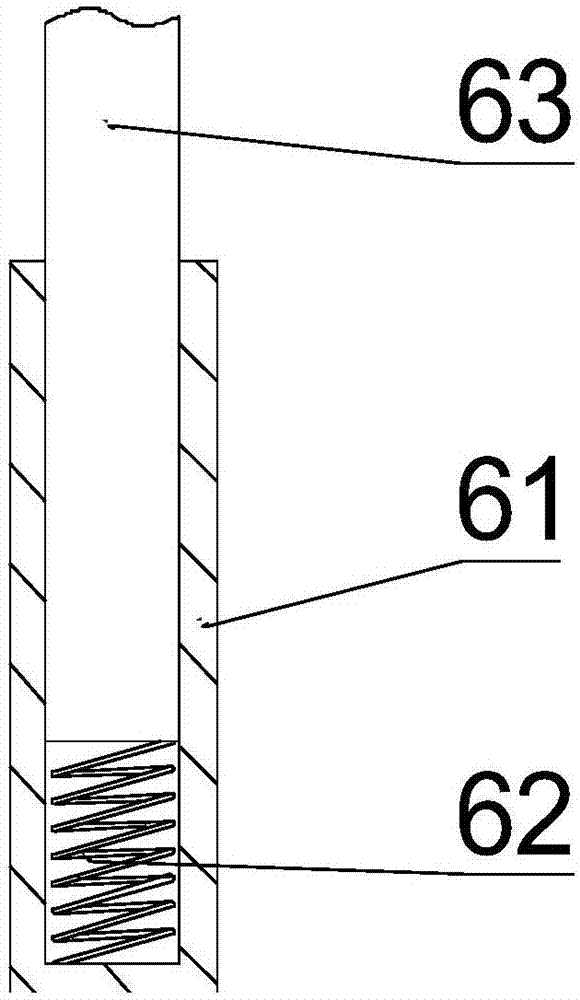

[0019] see Figure 1-4, a sorting and drying device for feed processing production, comprising a blanking cylinder 1, a first screen 10, a connecting box 9, a small particle receiving bin 11, a high-pressure fan 8, a large particle screening box 2, and a second screen 13. Elastic expansion device 6, vibration motor 14, iron slag removal device 7, outer shell 3, inner shell 4, rotating column 16, blower 19, air duct type gas heater 20, inclined cylindrical rotating cylinder 17, rotating ring 22 and Fixed ring 21, the upper left side of the large particle screening box 2 is fixedly connected with the blanking cylinder 1, the left side of the blanking cylinder 1 is equipped with a high-pressure fan 8, the air outlet end of the high-pressure fan 8 is connected to the inside of the blanking cylinder 1 The middle phase is connected, and the right side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com