Flue gas denitration equipment

A denitrification and equipment technology, applied in the direction of gas treatment, mixer, membrane technology, etc., can solve the problems of affecting the reduction degree of nitrogen oxides, inability to fully mix, and reduce performance, so as to facilitate mixing, promote mixing effect, The effect of increasing the mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

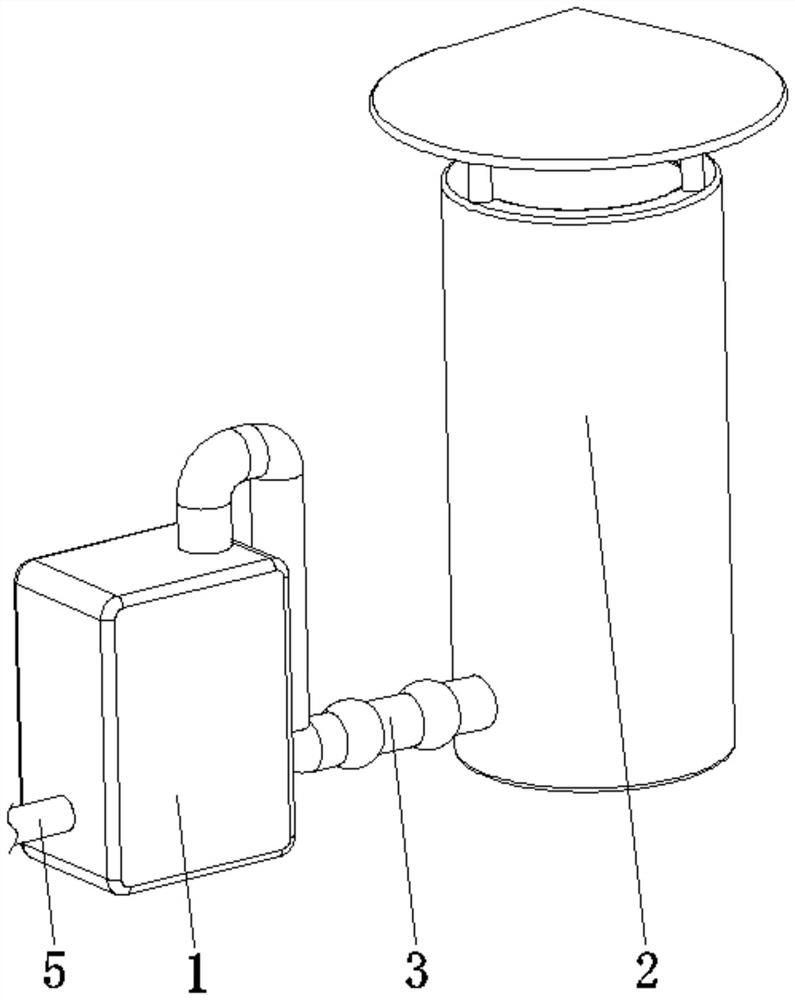

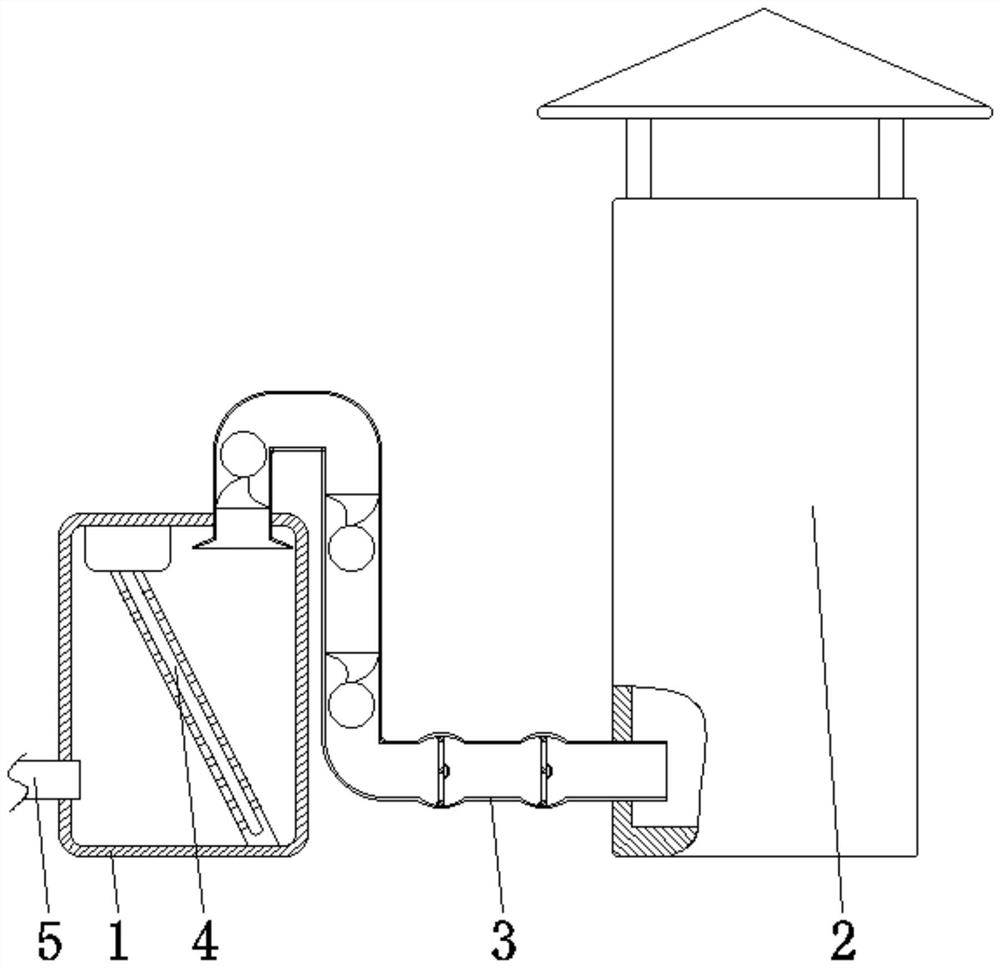

[0034] see Figure 1-8, the present invention provides a technical solution: a flue gas denitrification equipment, including a mixing chamber 1, a denitrification chamber 2, a delivery pipe device 3, an ammonia injector 4, and an air intake pipe 5, and the delivery pipe device 3 is fixedly connected between the mixing chamber 1 and the Between the denitrification chambers 2, the ammonia injector 4 is arranged inside the mixing chamber 1, and the air inlet pipe 5 is fixed on the bottom side of the surface of the mixing chamber 1 and communicates with the mixing chamber 1;

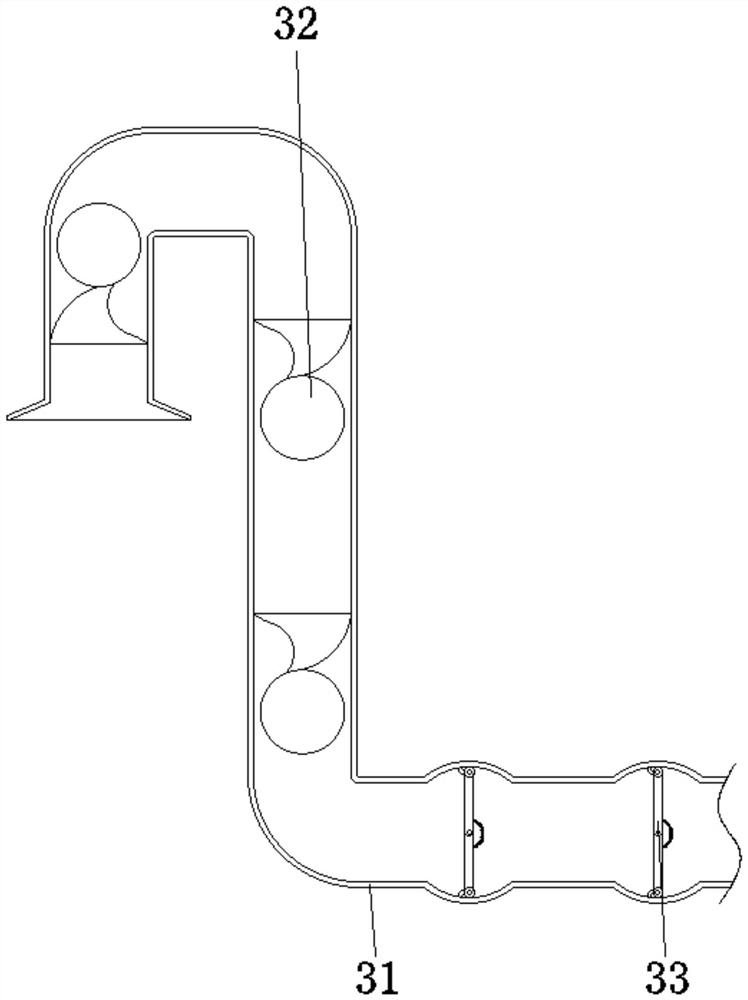

[0035] The conveying pipe device 3 is provided with a meandering pipe 31, a primary mixing device 32, and a secondary mixing device 33. One end of the meandering pipe 31 communicates with the top side of the mixing chamber 1, and the end of the meandering pipe 31 away from the mixing chamber 1 is connected to the denitrification chamber 2. The bottom side of the surface of the surface is connected, the prima...

Embodiment example 2

[0039] The secondary mixing device 33 is provided with a first flow guiding device 331, a second flow guiding device 332, an arc spring 333, and a limit block 334. Inside, one end of the first flow guiding device 331 is rotationally connected to one end of the second flow guiding device 332, and the arc spring 333 is fixed at a position corresponding to the surface of the first flow guiding device 331 and the surface of the second flow guiding device 332 The ends of the first flow guiding device 331 and the second flow guiding device 332 away from the arc spring 333 are connected to the inner wall of the meandering pipe 31 by rollers, and the limit block 334 is fixed on the inner wall of the meandering pipe 31 and close to the first flow guiding device 331, the position of the end of the second flow guide device 332, under the blowing of the gas, the first flow guide device 331 and the second flow guide device 332 are both turned into a V shape, and the mixed gas after the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com