High-efficiency mixer for producing neodymium-iron-boron magnet

A neodymium-iron-boron and mixer technology, which is applied to mixers, mixers with rotating containers, mixer accessories, etc., can solve the problems of inability to mix materials uniformly, low equipment efficiency, and affect production progress, saving time, Improved efficiency, improved mixing quality and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

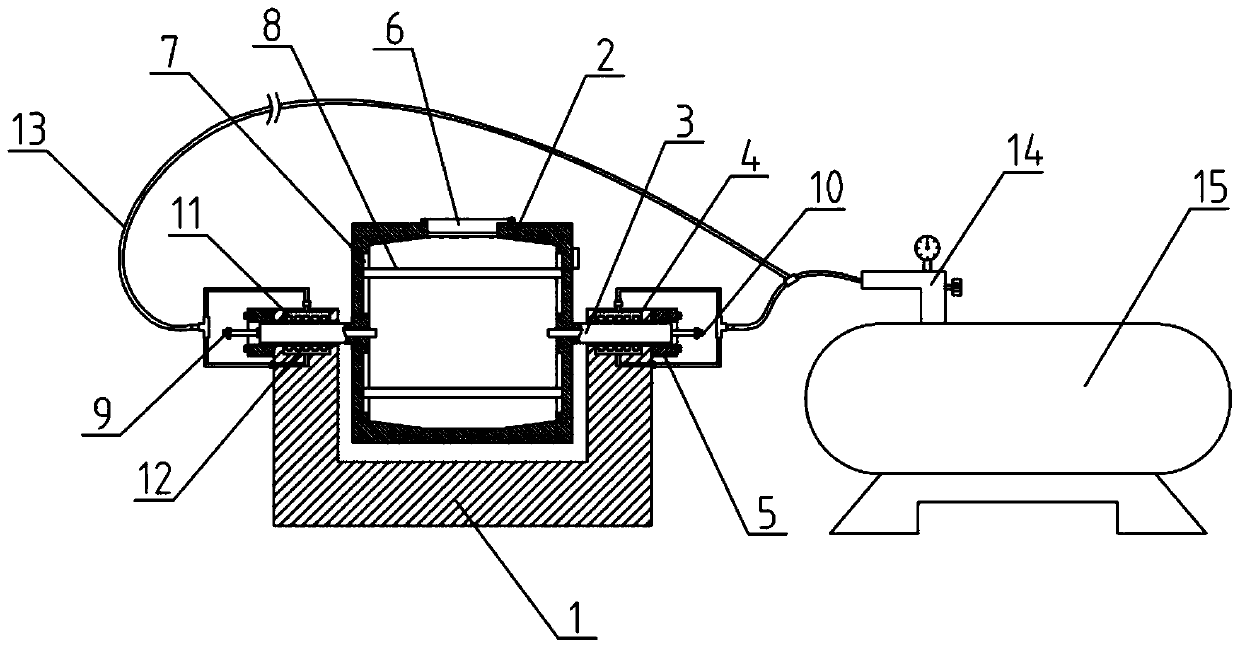

[0025] as attached figure 1 to attach Figure 4 shown

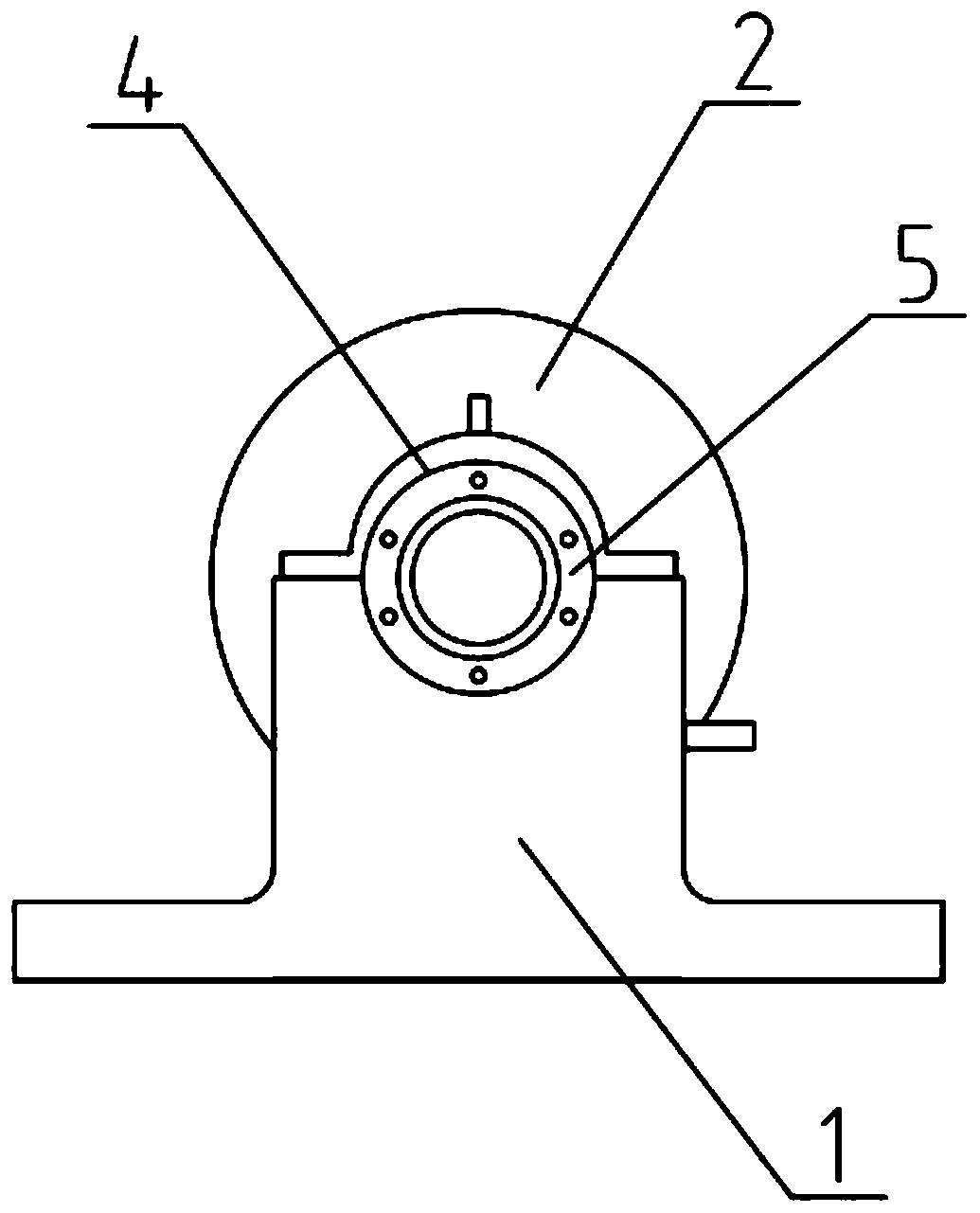

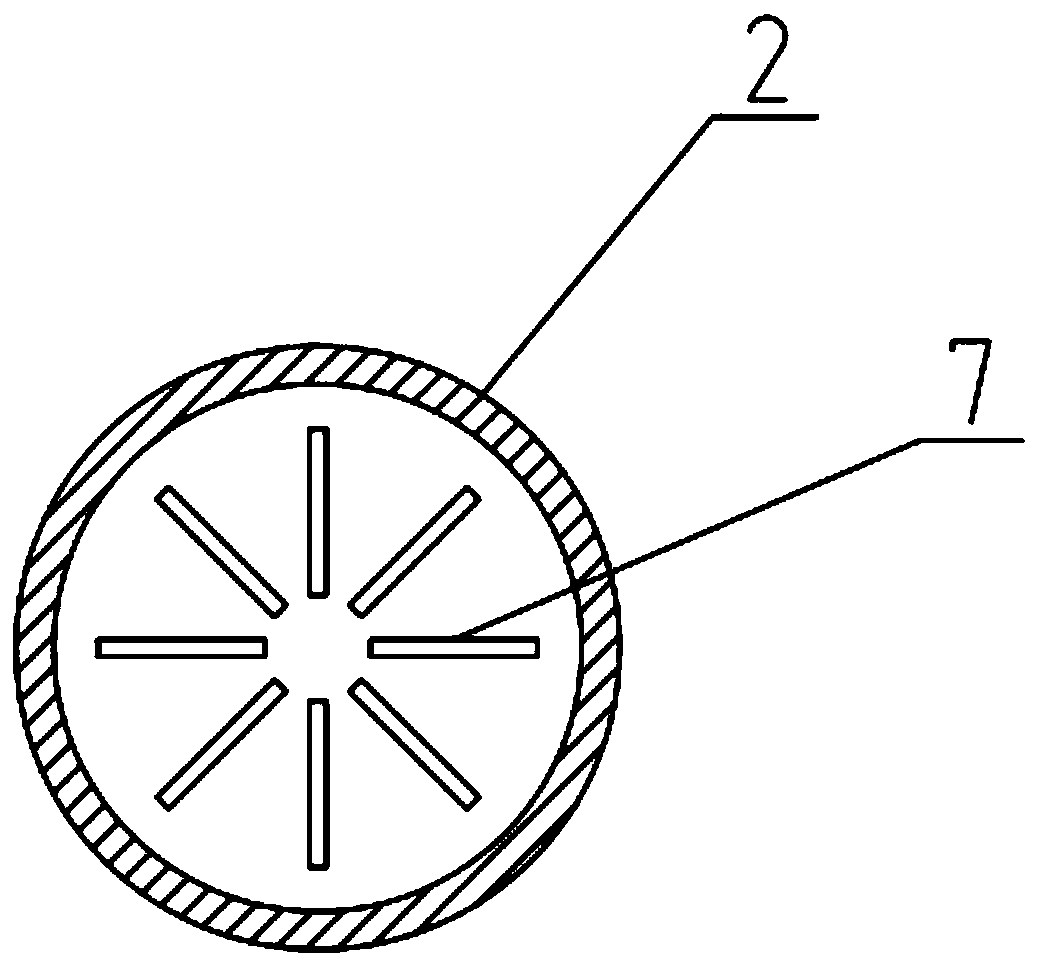

[0026] The invention provides a high-efficiency mixing machine for the production of NdFeB magnets, which includes a base 1, a rotating box 2, a support shaft 3, a bearing bush 4, a protective cover 5, an opening 6, a sliding groove 7, a mixing rod 8, and a nitrogen inlet 9 , a nitrogen outlet 10, an upper floating hole 11, a lower floating hole 12, an air intake pipe 13, an air cleaner 14 and an air pump device 15, and the middle part of the two sides of the rotating box 2 is symmetrically provided with a support shaft 3, and the support shaft 3 is erected on the The upper part of the base 1, the upper part of the support shaft 3 is connected with the bearing bush 4 that defines the radial position of the support shaft 3, and the end of the support shaft 3 is connected with the cover 5 that defines the axial position of the support shaft 3;

[0027] The rotary box 2 is set as a cylindrical sealed box, and the outer mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com