Forage smashing device for animal husbandry

A crushing device and fodder technology, which is applied in application, feed, transportation and packaging, etc., can solve the problems of poor crushing effect, unfavorable forage and other feed ingredients fully mixed, and inability to remove dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

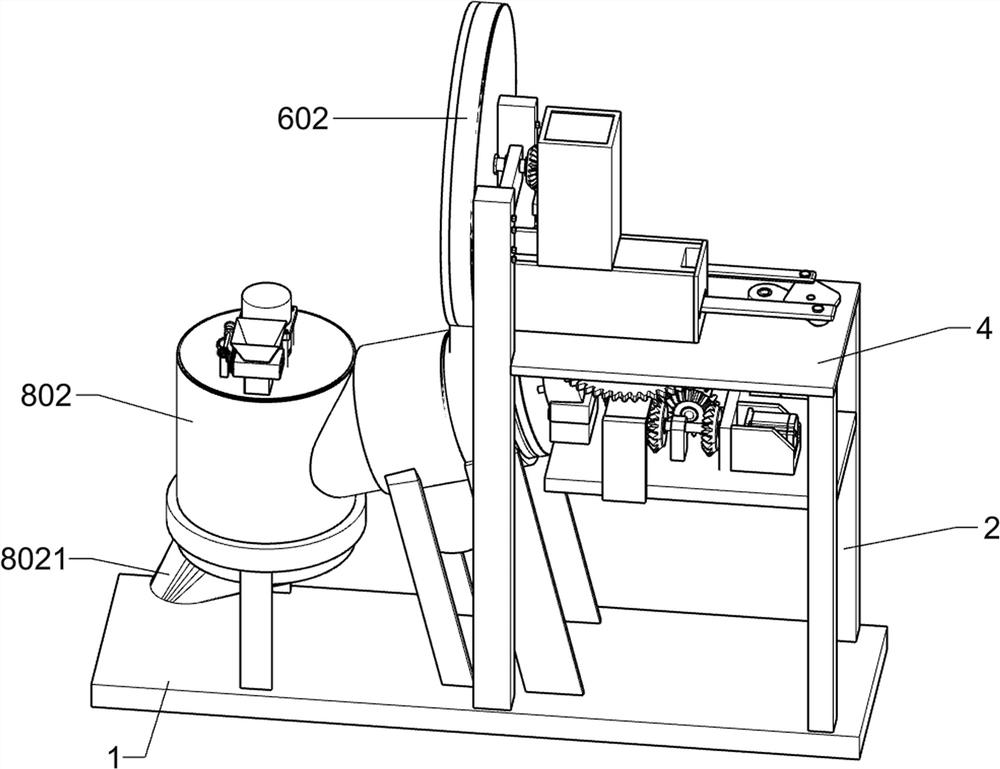

[0027] A kind of forage crushing device for animal husbandry, such as figure 1As shown, it includes the bottom plate 1, the outriggers 2, the horizontal plate 3, the gear device, the first frame 301, the machine sleeve 305, the convex plate 4, the feeding device, the inclined plate 5, the long leg 6, the horizontal bar 601, the cutting device , the second support rod 7, the short rod 8 and the circle 801, the bottom plate 1 is fixedly installed with the outrigger 2, the inclined plate 5, the long leg 6, the second support rod 7 and the short rod 8, among which the outrigger 2, the inclined plate 5 , The long leg 6, the second support rod 7 and the short rod 8 are each provided with two symmetrically front and rear, the leg 2 is installed on the far right of the bottom plate 1, the short rod 8 is installed on the left side of the bottom plate 1, the inclined plate 5, the long leg 6, The second strut 7 is installed in the middle of the bottom plate 1, and the inclined plate 5, t...

Embodiment 2

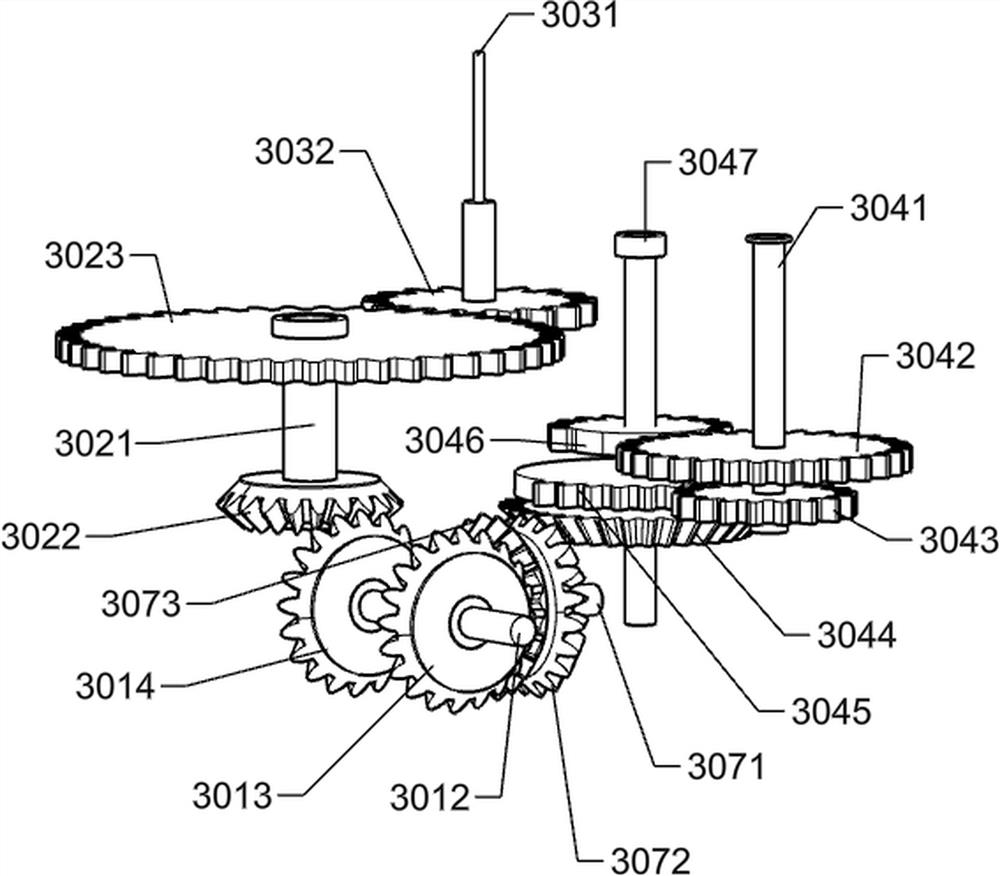

[0030] On the basis of Example 1, as Figure 2-6 As shown, the gear device includes a first motor 3011, a first shaft 3012, a first gear 3013, a second gear 3014, a first T-frame 302, a second shaft 3021, a third gear 3022, a fourth gear 3023, a second T-frame 303, third shaft 3031, fifth gear 3032, third T-frame 304, fourth shaft 3041, sixth gear 3042, seventh gear 3043, eighth gear 3044, ninth gear 3045, tenth gear 3046, The fifth shaft 3047, the first strut 306, the support plate 307, the sixth shaft 3071, the eleventh gear 3072 and the twelfth gear 3073, the horizontal plate 3 is fixedly connected with the first frame 301 and the first T frame 302 , the second T frame 303, the third T frame 304, the first strut 306 and the support plate 307, wherein the first T frame 302 is located on the left front side of the horizontal plate 3, and the first frame 301 is located on the upper right side of the horizontal plate 3, The first support rod 306 is located on the left side of ...

Embodiment 3

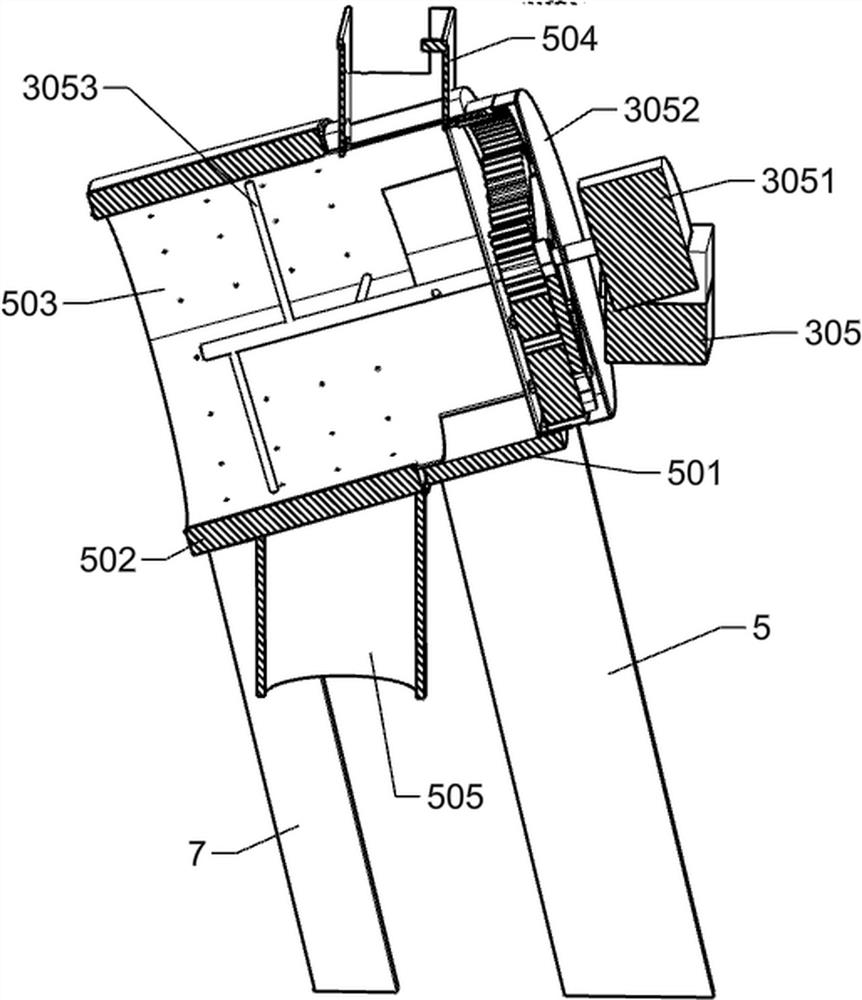

[0039] On the basis of Example 2, as Figure 7-9 As shown, it also includes a round sleeve 501, a sliding barrel 502, a hole barrel 503, a feeding channel 504, a waste barrel 505, a second motor 3051, a planetary gear set 3052 and a stirring rod 3053, and the round sleeve 501 is fixedly connected to the swash plate 5. The upper end of the sliding barrel 502 is fixedly connected to the upper end of the second strut 7, the right end of the hole barrel 503 is provided with a rack, the hole barrel 503 is sleeved on the inner wall of the round sleeve 501 and the sliding barrel 502, and the upper right of the hole barrel 503 is fixedly connected There is a feeding channel 504, a waste barrel 505 is fixedly connected to the lower left of the hole barrel 503, the upper end of the feeding channel 504 is fixedly connected to the lower surface of the casing 602, the second motor 3051 is fixedly connected to the machine sleeve 305, and the stirring rod 3053 passes through The hole barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com