Preparation method of ultrahigh-purity copper-manganese alloy

A manganese alloy and pure copper technology, which is applied in the field of ultra-high-purity copper-manganese alloy target manufacturing, can solve problems such as uneven alloy composition and alloy carbon particle inclusions, and achieve uniform ultra-high-purity copper-manganese alloys and reduced carbon particle inclusions , wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

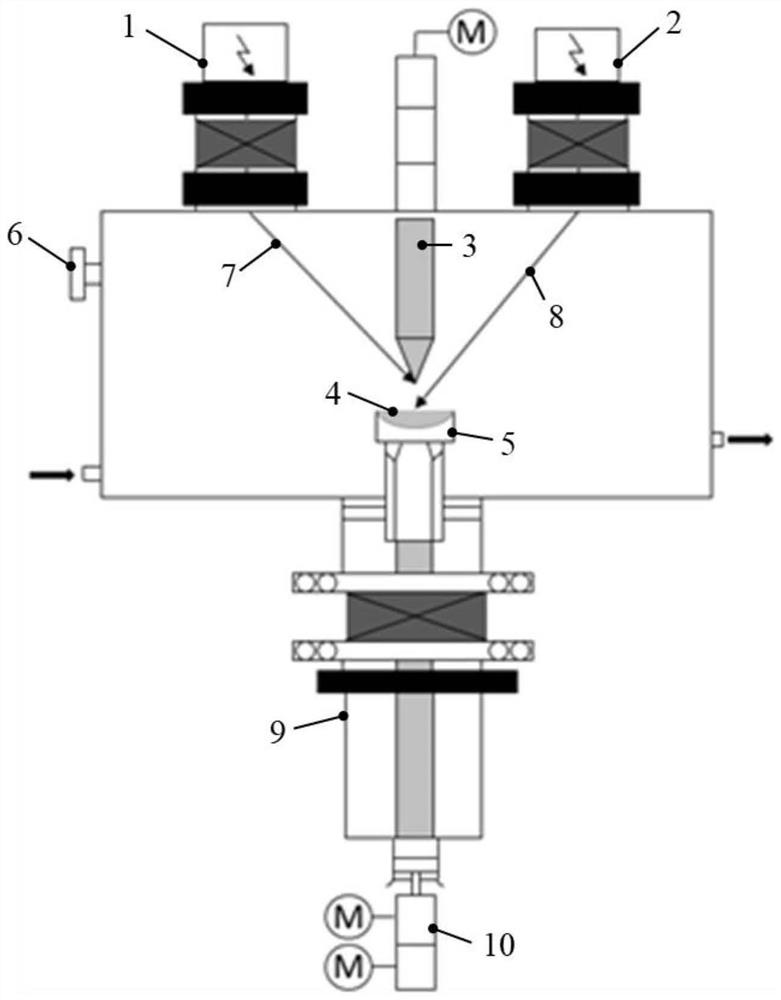

Method used

Image

Examples

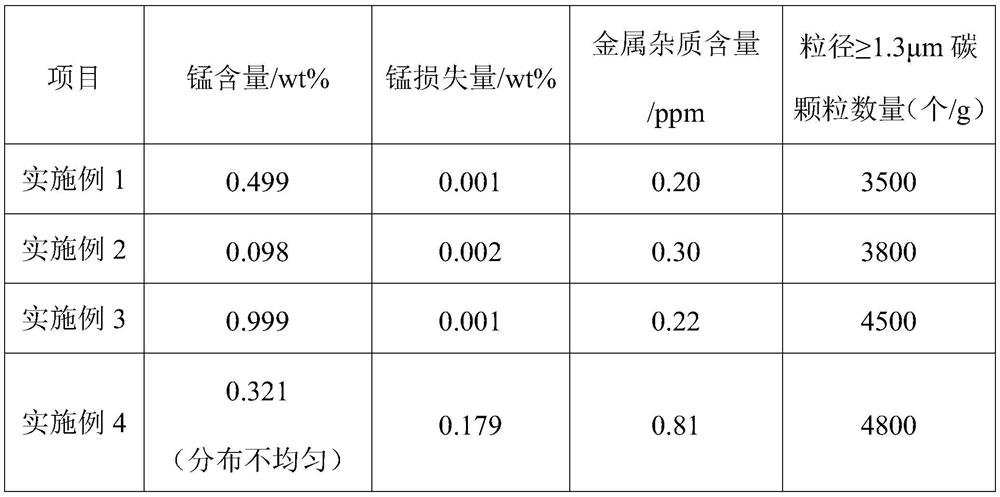

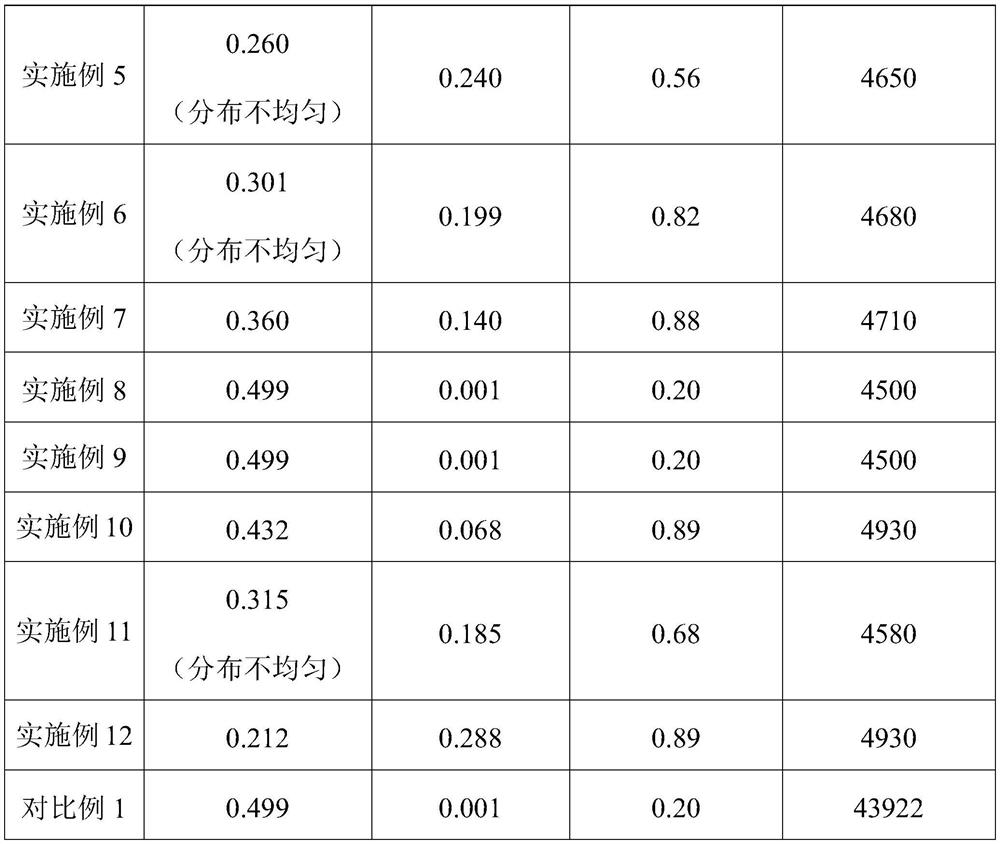

Embodiment 1

[0067] This embodiment provides a method for preparing an ultra-high-purity copper-manganese alloy, the preparation method comprising the following steps:

[0068] (1) Adopting a nitric acid aqueous solution with a purity of 30wt% as the pickling liquid, pickling the ultra-high-purity copper electrolytic sheet with a purity of 99.9999wt% and the manganese electrolytic sheet with a purity of 99.999wt%, and then mixing the two raw materials Carry out hot isostatic pressing, control the temperature of hot isostatic pressing to be 900 ℃, the pressure is 200MPa, and the dwelling time is 5.5h, obtains the ultrahigh-purity copper-manganese alloy billet that Mn content is 0.5wt%, and the ultrahigh-purity The copper-manganese alloy billet is cylindrical with a diameter of 200mm and a height of 1000mm;

[0069] (2) After the ultra-high-purity copper-manganese alloy blank described in step (1) is fixed directly above the water-cooled copper crucible in the electron beam melting furnace, ...

Embodiment 2

[0072] This embodiment provides a method for preparing an ultra-high-purity copper-manganese alloy, the preparation method comprising the following steps:

[0073] (1) Adopting a nitric acid aqueous solution with a purity of 32wt% as the pickling solution, pickling the ultra-high-purity copper electrolytic sheet with a purity of 99.99995wt% and the manganese electrolytic sheet with a purity of 99.9995wt%, and then mixing the two raw materials Carrying out hot isostatic pressing, controlling the temperature of hot isostatic pressing to be 850°C, the pressure to be 180MPa, and the holding time to be 6h, to obtain an ultra-high-purity copper-manganese alloy billet with a Mn content of 0.1wt%, and the ultra-high-purity copper The manganese alloy billet is cylindrical with a diameter of 190mm and a height of 900mm;

[0074] (2) After the ultra-high-purity copper-manganese alloy blank described in step (1) is fixed directly above the water-cooled copper crucible in the electron beam...

Embodiment 3

[0077] This embodiment provides a method for preparing an ultra-high-purity copper-manganese alloy, the preparation method comprising the following steps:

[0078] (1) Adopting a nitric acid aqueous solution with a purity of 28wt% as the pickling solution, pickling the ultra-high-purity copper electrolytic sheet with a purity of 99.99992wt% and the manganese electrolytic sheet with a purity of 99.9995wt%, and then mixing the two raw materials Carry out hot isostatic pressing, control the temperature of hot isostatic pressing to be 950°C, the pressure to be 190MPa, and the holding time to be 5h to obtain an ultra-high-purity copper-manganese alloy blank with a Mn content of 1.0wt%, and the ultra-high-purity copper The manganese alloy billet is cylindrical with a diameter of 210mm and a height of 1100mm;

[0079] (2) After the ultra-high-purity copper-manganese alloy blank described in step (1) is fixed directly above the water-cooled copper crucible in the electron beam melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com