Multifunctional mixing equipment used for thermal insulation coating

A technology for mixing equipment and thermal insulation coatings, applied in mixers, jitter/oscillation/vibration mixers, mixers with rotating stirring devices, etc., can solve problems such as uneven coating temperature, improve production quality, ensure performance, The effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through specific implementations:

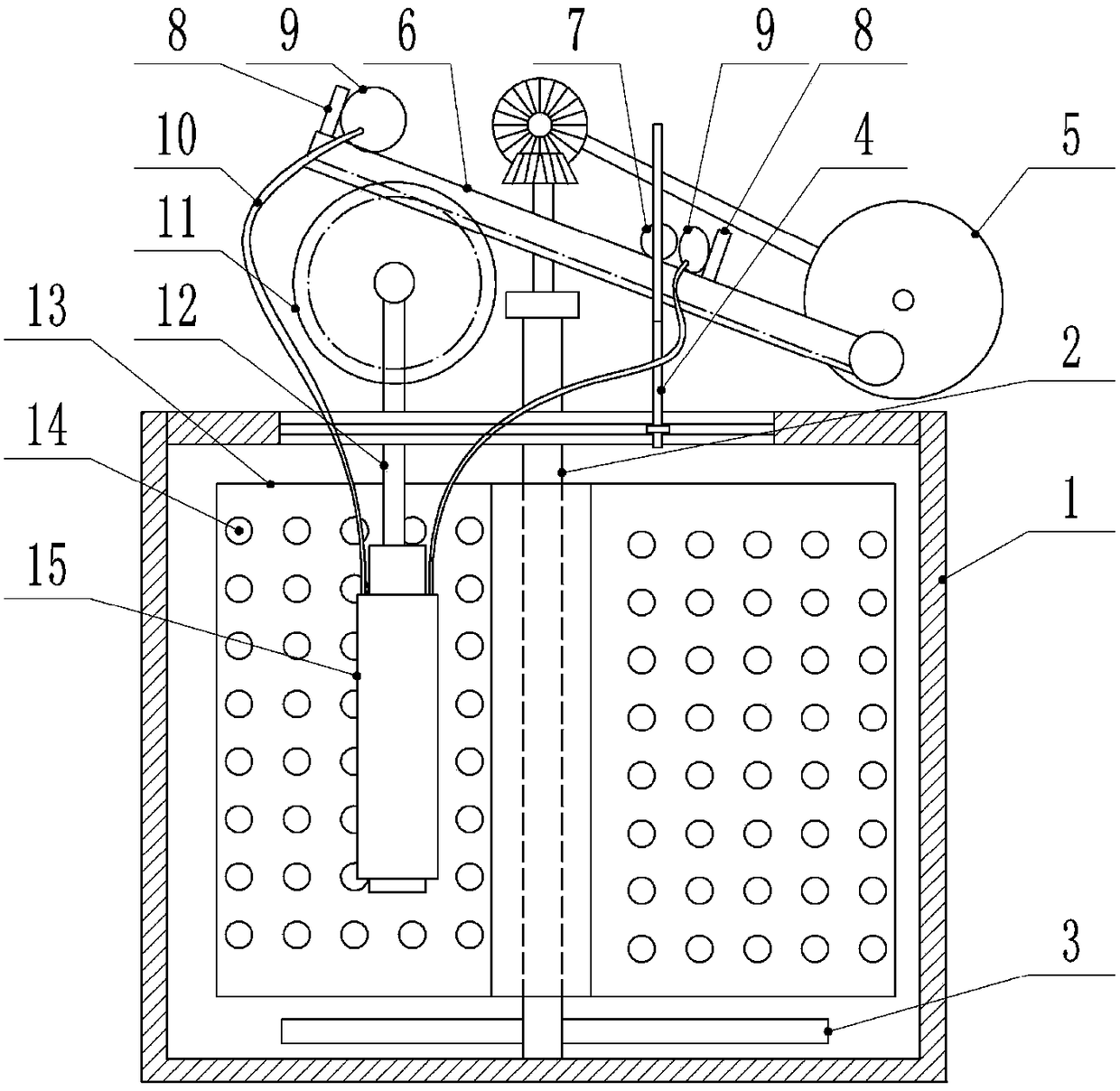

[0018] The reference signs in the drawings of the specification include: box body 1, stirring shaft 2, stirring arm 3, connecting head 4, runner 5, rack 6, sliding block 7, limit block 8, air bag 9, air blast tube 10, Gear 11, swing arm 12, stirring plate 13, through hole 14, sleeve 15.

[0019] The implementation is basically like figure 1 Shown: multifunctional mixing equipment for thermal insulation coatings, including box 1, stirring mechanism, blowing mechanism, reciprocating mechanism, transmission mechanism, toggle mechanism and blast mechanism.

[0020] The stirring mechanism is used to stir the paint in the box 1, and its structure includes a stirring shaft 2 which is arranged in the box 1 through a bearing rotation and extends vertically. The stirring shaft 2 is rotatably connected with a stirring head through the bearing. The stirring head includes four sides The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com