Multi-line reactor

A technology of reactors and reaction tubes, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problem of uneven mixing of reactants, insufficient reaction, There is no problem with installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

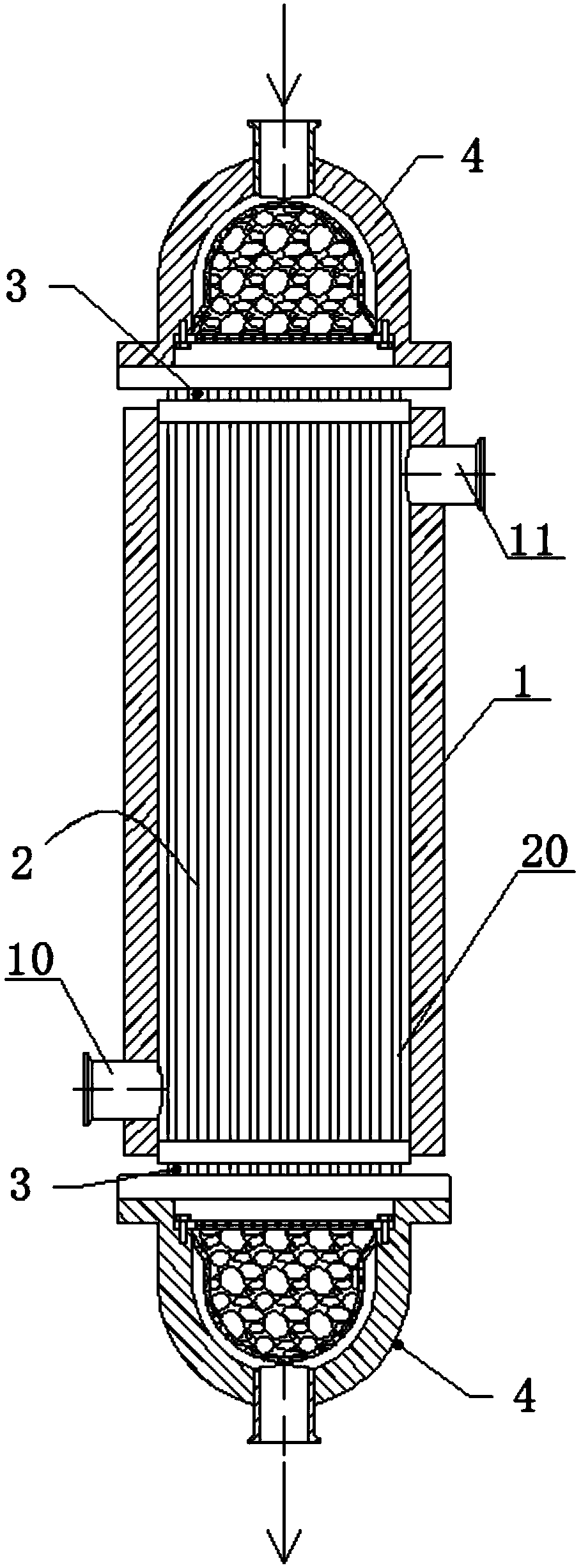

[0020] Embodiment 1, a multi-line reactor, is characterized in that it includes a shell 1, a reaction tube group 2, a tube sheet 3 and a head 4, and the upper and lower ends of the shell 1 are respectively connected with the tube sheets 3.

[0021] The housing 1 is provided with a reaction tube group 2, the reaction tube group 2 includes a plurality of reaction tubes 20, the reaction tubes 20 are straight tubes arranged in parallel, and the upper and lower ends of each reaction tube 20 pass through and are fixedly connected On the tube sheet 3 and communicated with the mixing chamber 43.

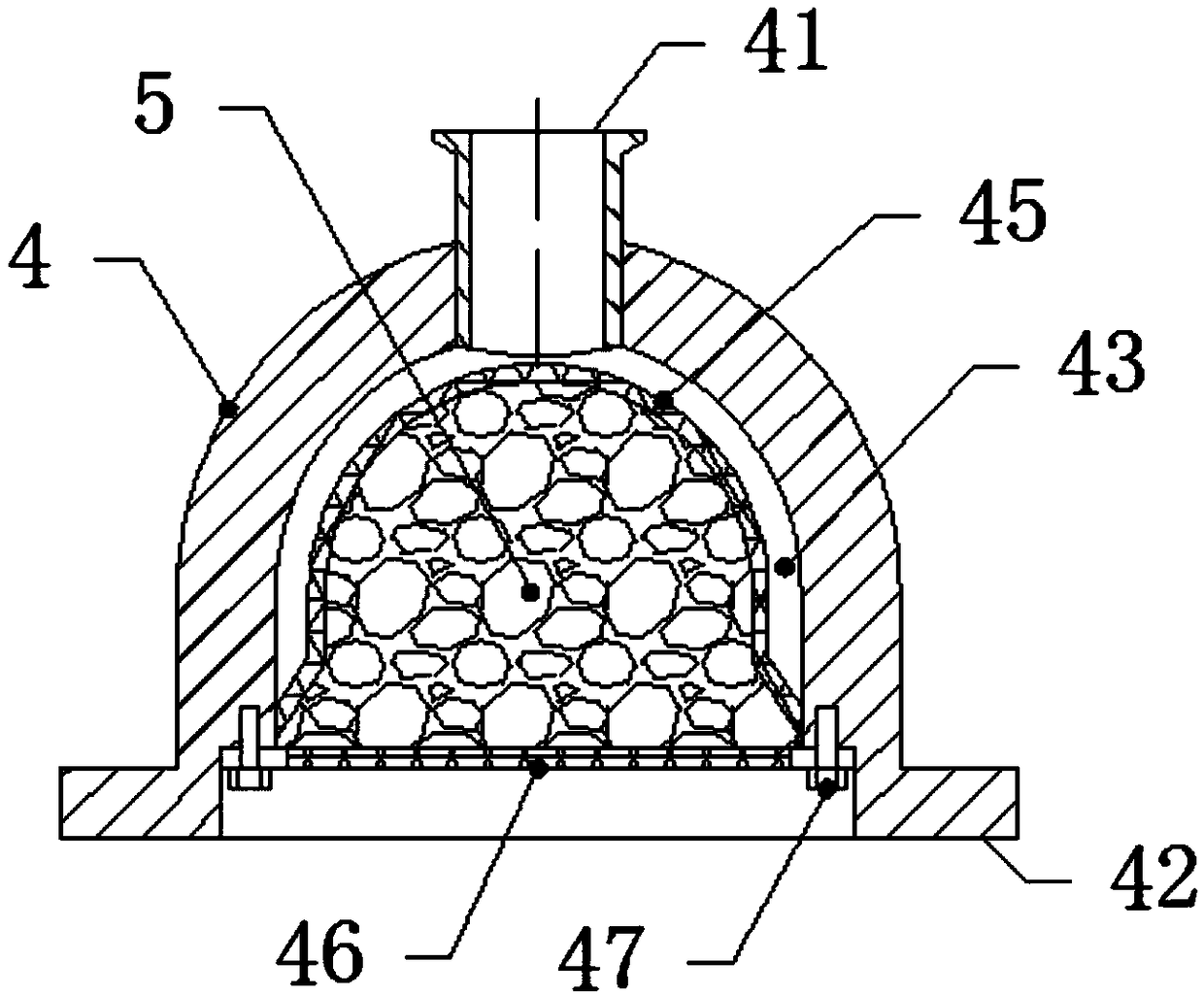

[0022] The upper and lower ends of the housing 1 are all provided with a head 4, and the head 4 is connected with the tube sheet 3, such as image 3 As shown, specifically, the lower end of the head 4 is provided with a connecting flange 42, which is connected to the tube sheet 3 through the connecting flange 42. The head 4 is a cavity structure with upper and lower openings, and is connecte...

Embodiment 2

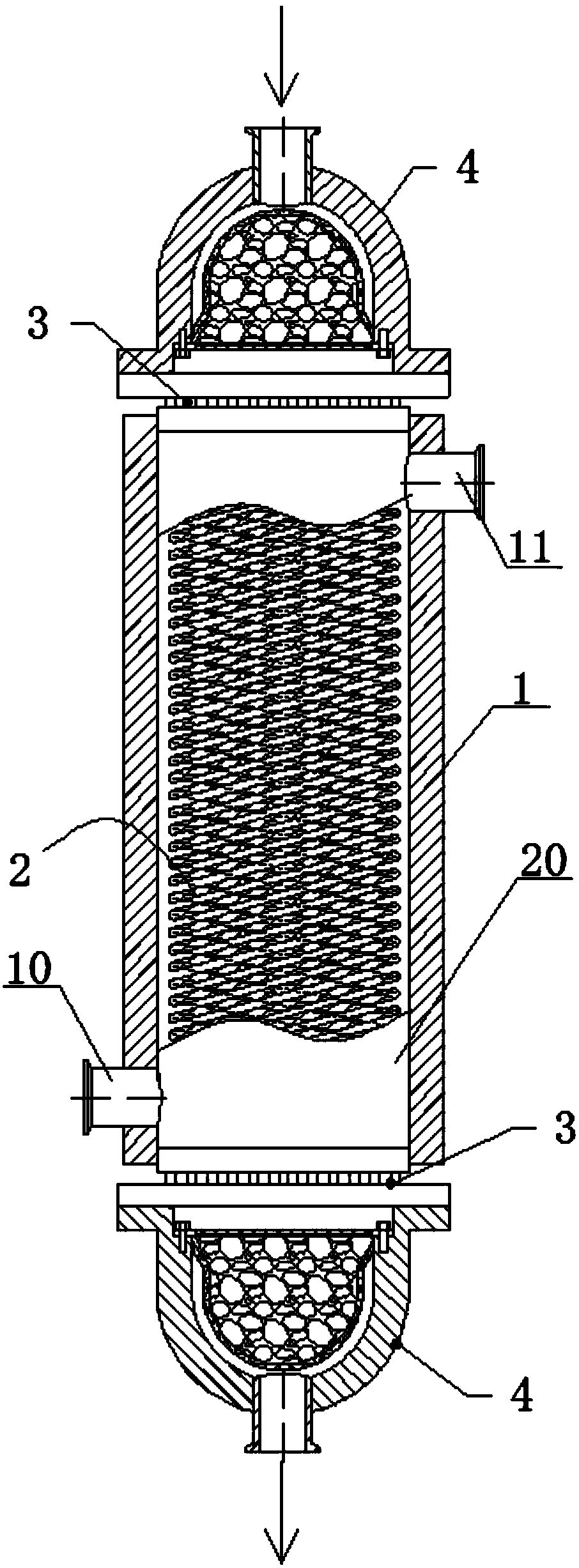

[0029] Example 2, such as figure 2 As shown, the reaction tube 20 is a helically wound tube with a certain helix angle, which can slow down the speed of the reactants passing through the reaction tube 20, make the rotary cutting rise, mix more uniformly, and react more fully.

[0030] Such as figure 1 , 2 As shown, the lower and upper parts of the housing 1 are respectively provided with a shell-side inlet 10 and a shell-side outlet 11, the temperature-controlled liquid enters through the shell-side inlet 10, is discharged from the shell-side outlet 11, and passes through the outer wall of the reaction tube 20 in the middle , adjust the temperature of the reaction tube 20 to ensure the temperature required for the reaction of the reactants, and improve the adequacy and stability of the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com