Powder material mixing device

A powder material and mixing device technology, applied in the direction of mixers, fluid mixers, transportation and packaging, etc., can solve the problems of cumbersome installation, large wear and tear of mechanical equipment, high energy consumption, etc., and achieve easy maintenance, reliable operation, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

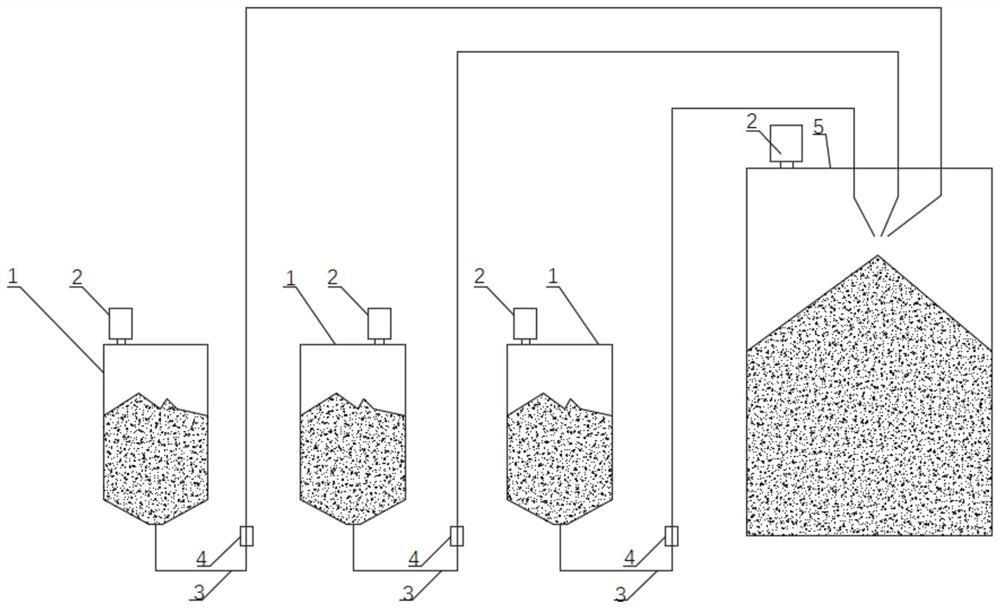

[0014] Such as figure 1 As shown, a powder material mixing device includes a mixing bin 5 and several powder bins 1 for storing different powder materials. The bottom of each powder bin 1 is provided with an independent pneumatic conveying mechanism 3, and the pneumatic conveying mechanism 3 There are independent flow adjustment components 4 on the top, and the ends of the pneumatic conveying mechanism 3 are all connected to the mixing chamber 5 from the top and point downward. Dimensions within a horizontal circle. The pneumatic conveying mechanism 3 belongs to airtight conveying, and the conveying process is environmentally friendly. Since the pneumatic conveying mechanism 3 is easy to adjust and install, there are no restrictions on the distance and position between the powder bins 1 and between the powder bin 1 and the mixing bin 5, and the occupie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com