Oil-control resistance-lowering cylindrical roller bearing

A cylindrical roller bearing and drag reduction technology, applied in the field of bearings, can solve problems such as the uncontrollable flow of lubricating oil, and achieve the effects of simple structure, reduced energy loss, and reduced carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

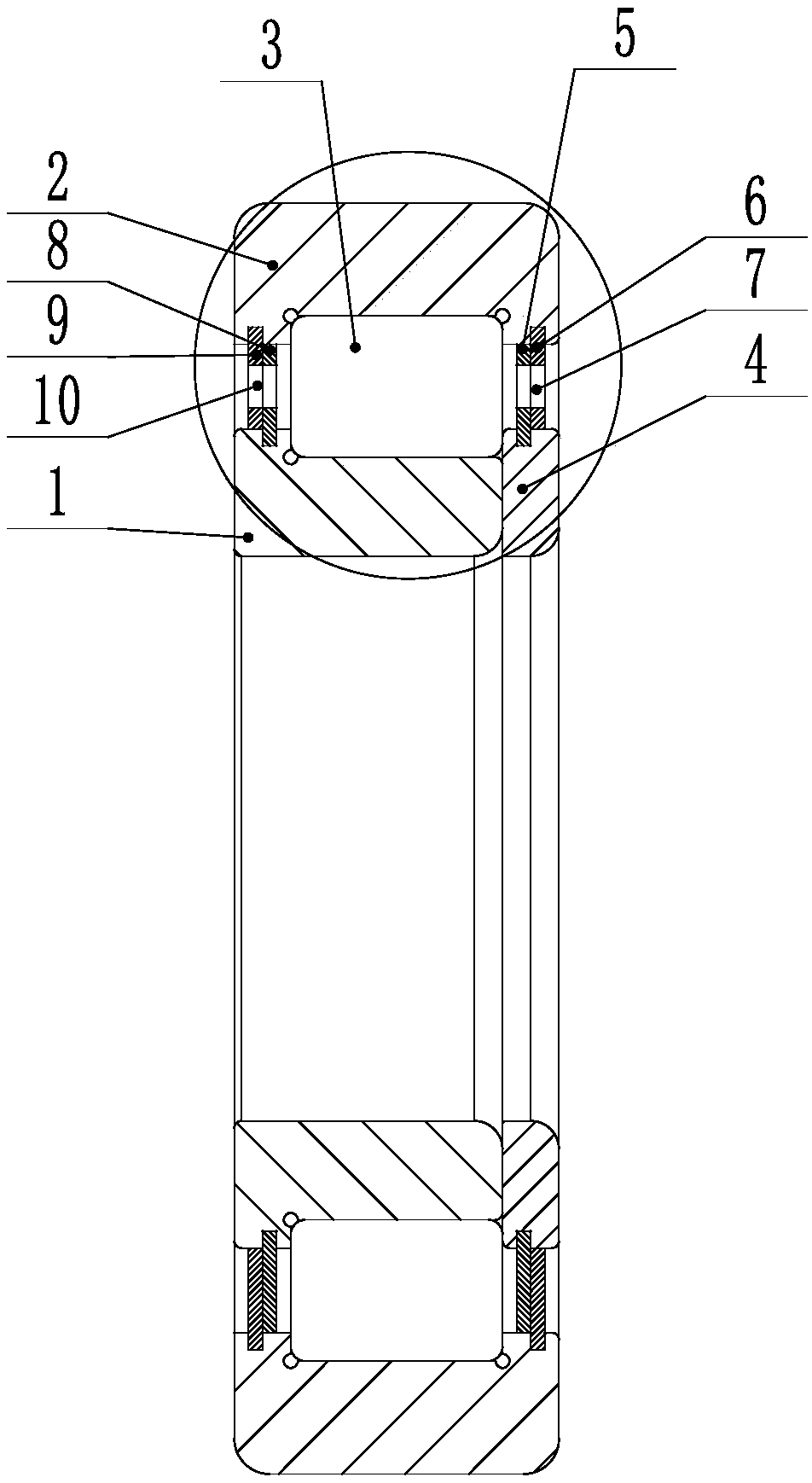

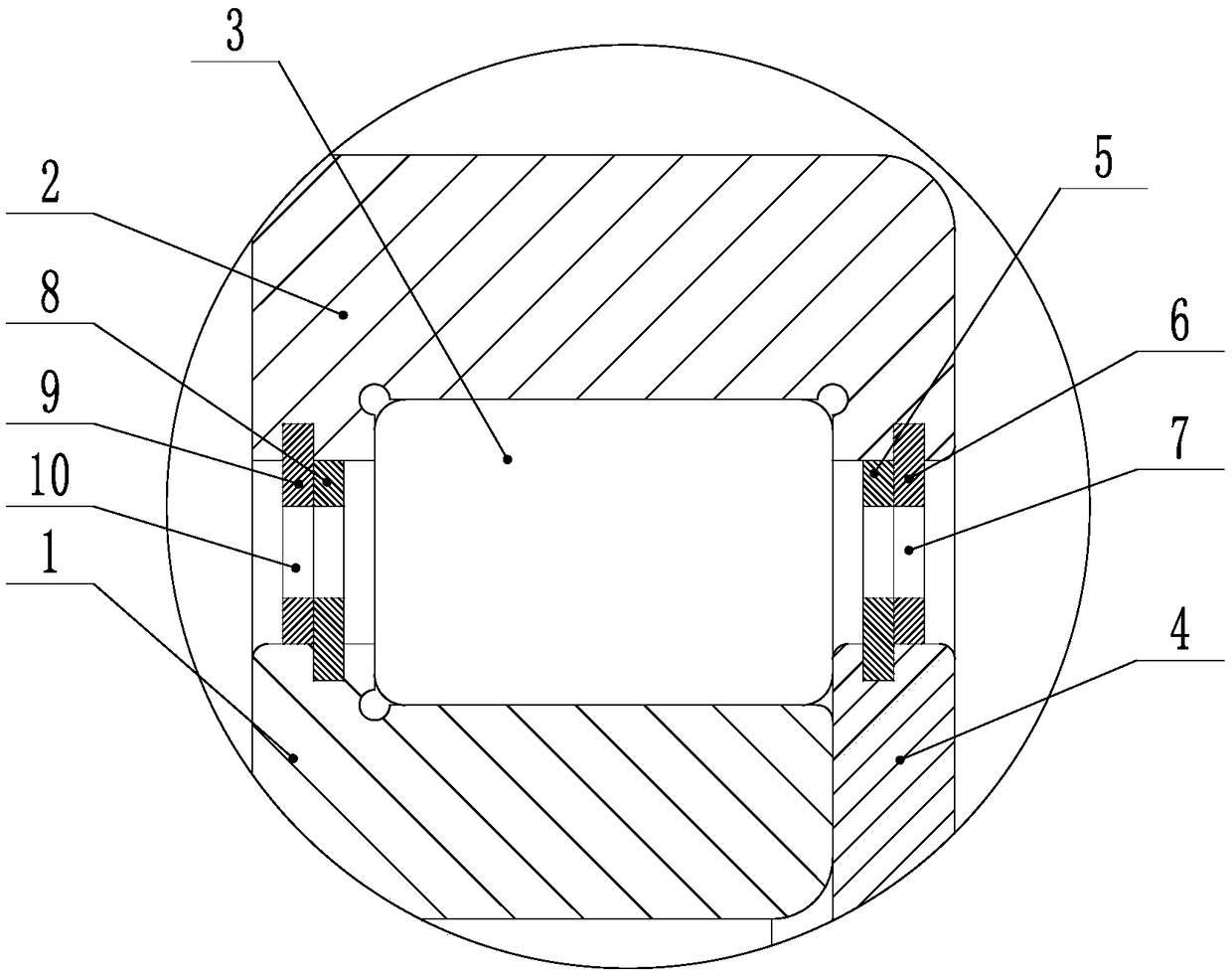

[0020] The present invention will be further described below with specific embodiment, see figure 1 -5:

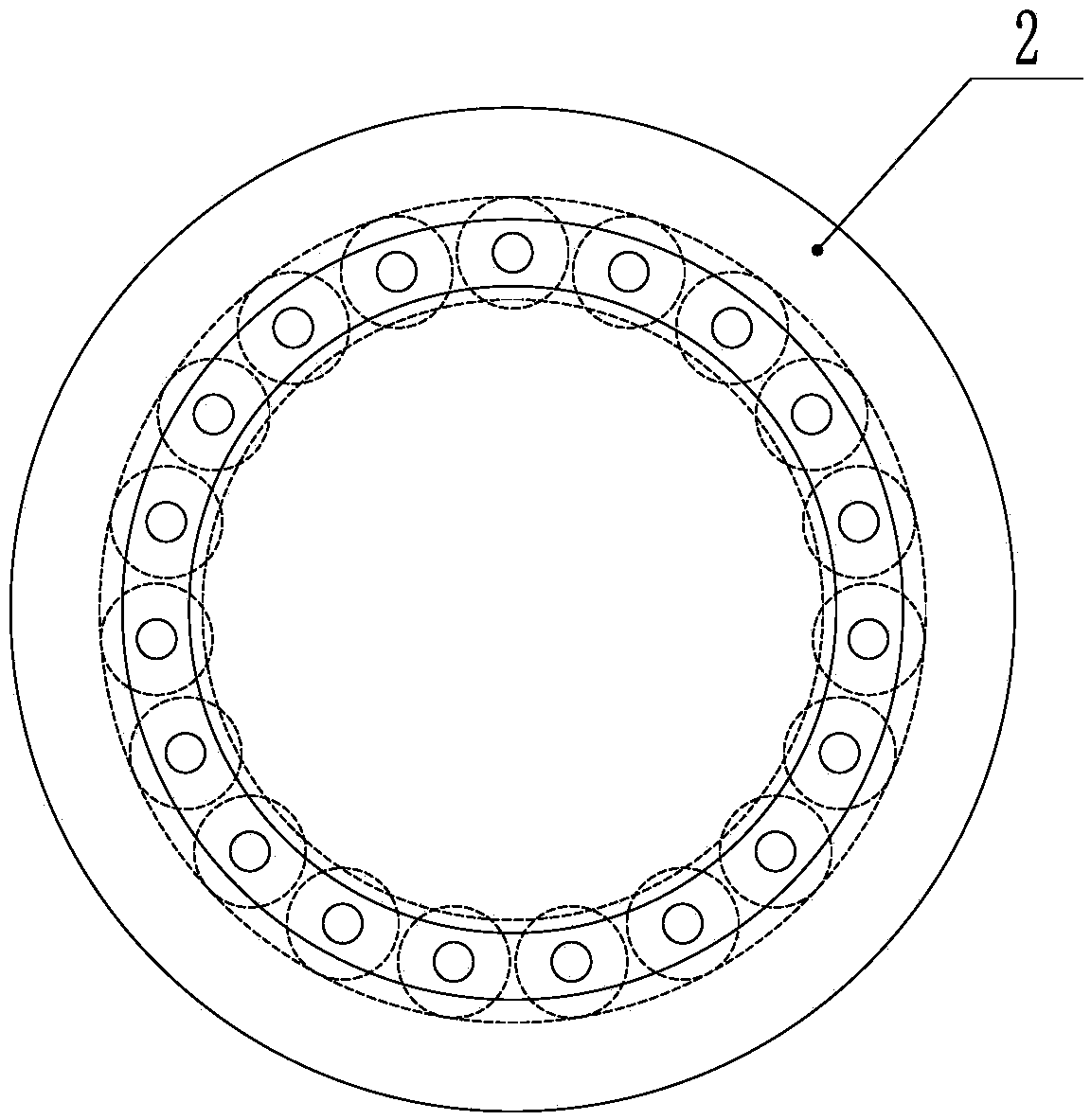

[0021] A cylindrical roller bearing for oil control and drag reduction, comprising a bearing inner ring 1, a bearing outer ring 2 and several cylindrical rollers 3 uniformly distributed in the circumferential direction between the bearing inner ring 1 and the bearing outer ring 2, the bearing inner ring 1 The axial dimension is smaller than the axial dimension of the bearing outer ring 2, the bearing inner ring 1 and the bearing outer ring 2 are aligned at the oil inlet end, and the end surface of the oil outlet end of the bearing inner ring 1 is provided with a bearing washer 4, and the bearing washer 4 passes through the inner outlet The oil ring 5 and the outer oil ring 6 are connected with the bearing outer ring 2, the inner oil ring 5 rotates with the bearing washer 4, the outer oil ring 6 rotates with the bearing outer ring 2, the inner oil ring 5, the outer ring Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com