Pretreatment equipment for flour processing and working method thereof

A pretreatment and flour technology, applied in grain processing, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reducing production efficiency, increasing labor operations, and small addition ratio, so as to increase efficiency and quality, increase Mixing effects, space-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

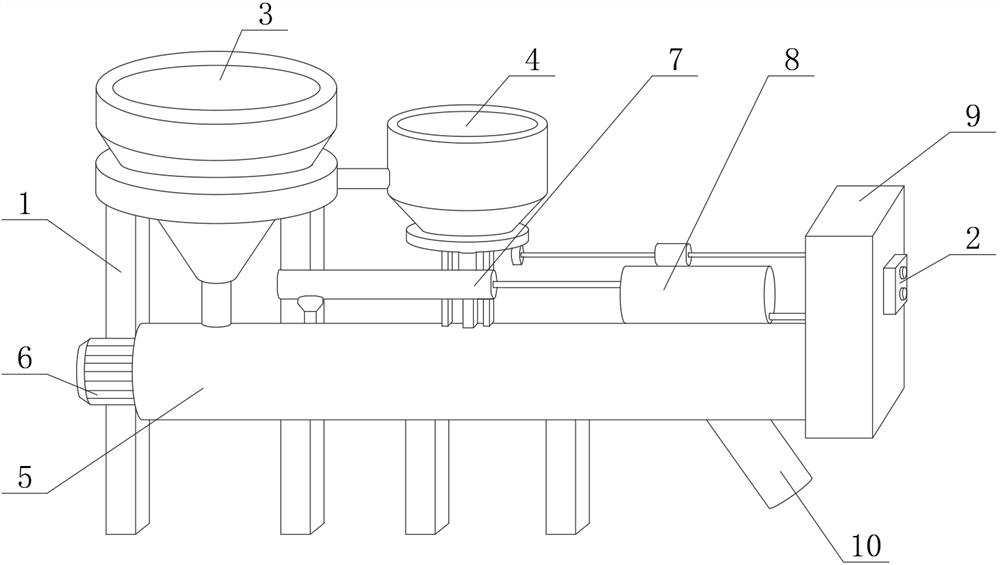

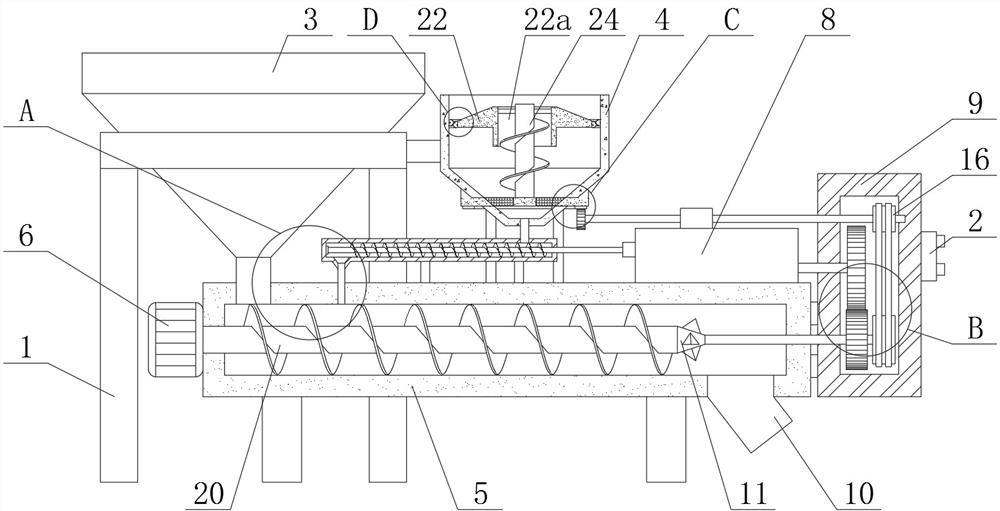

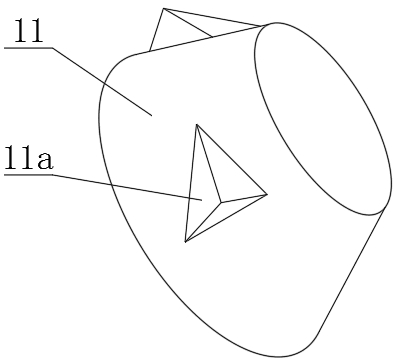

[0036] see figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 , the present invention provides a technical solution: a pretreatment equipment for flour processing, including a support frame 1 and a controller 2, the support frame 1 is fixedly provided with a flour lower hopper 3, an alkali powder lower hopper 4, a first conveying Cylinder 5 and the second conveying cylinder 7, flour lower hopper 3 and alkali powder lower hopper 4 are respectively used for preloading flour and alkali powder, and the bottom output port of flour lower hopper 3 is connected with the left end inner side of the first conveying cylinder 5, The flour on the inside of the flour lower hopper 3 can enter the left end inside of the first conveying cylinder 5, the bottom of the alkali powder lower hopper 4 is connected with the right end inside of the second conveying cylinder 7, and the alkali powder on the inner side of the alkali powder lower hopper 4 can pass through The feeding pipeline ent...

Embodiment 2

[0042] In this embodiment, the same part as Embodiment 1 will not be repeated, the difference is:

[0043] see figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 7 and Figure 8 , the present invention provides a technical solution:

[0044] The inner side of the bottom end of the alkali powder lower hopper 4 is rotated to be provided with a screen plate 19. When the first screw conveyor rod 20 rotates, the third gear 17 will be driven to rotate by the first runner 14, the transmission belt 15 and the second runner 16. , the rotation of the third gear 17 can drive the sieve plate 19 to rotate by the gear ring 18, and the rotation of the sieve plate 19 can play the effect of accelerating the sieve through the sieve 19a, ensuring that the diameter of the flour and the falling alkali powder is the same, The inner side of the sieve plate 19 is fixedly connected with a sieve 19a, the sieve 19a is arranged in a ring shape, and the top center of the sieve plate 19 is fixedl...

Embodiment 3

[0049] see Figure 1-8 , the present invention provides a technical solution:

[0050] A pretreatment method for flour processing, mainly comprising the following production steps:

[0051] Step 1, grinding operation, grinding edible alkali to obtain alkali powder with smaller diameter;

[0052] Step 2, sieving operation, sieving the alkali powder obtained in step 1 to obtain the alkali powder with the same diameter as the flour, so as to prevent concentration and stratification of flour and alkali powder due to shaking during subsequent transportation operations;

[0053] Step 3, proportioning operation; according to the ratio of 1000:1, the flour and the alkali powder obtained in step 2 are proportioned to obtain the flour and alkali powder configured in proportion;

[0054] Step 4, mixing operation, evenly mix the flour and alkali powder with a good ratio to obtain alkali noodles suitable for making noodles;

[0055]The pretreatment equipment used in the above operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com