Rotary stirring rare earth alloy smelting device

A rare earth alloy, rotary stirring technology, applied in stirring devices, crucible furnaces, furnaces, etc., can solve the problems of difficult post-cleaning, easy contamination of molten metal, and achieve the effect of preventing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

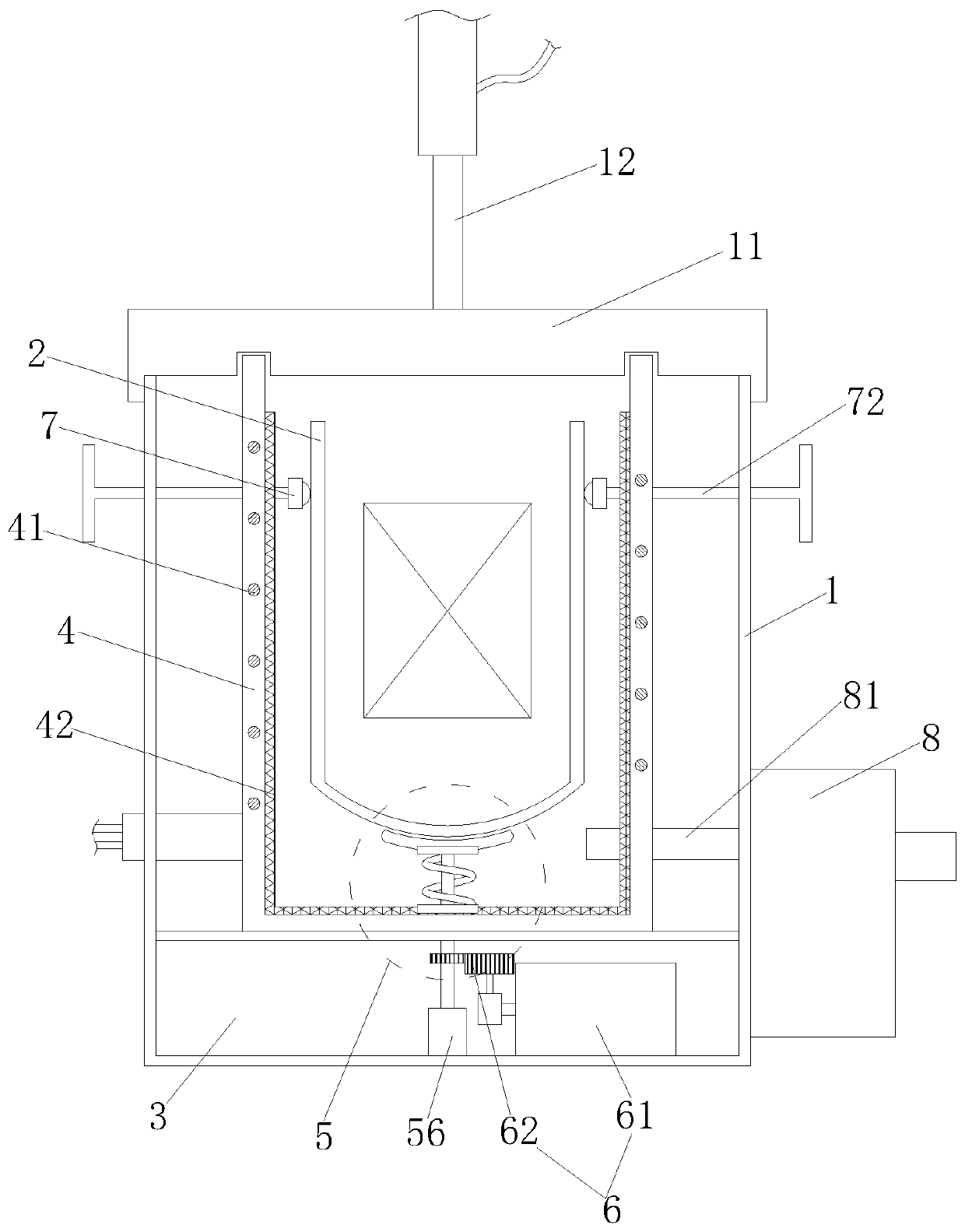

[0026] Such as figure 1 Shown: a rotating stirring rare earth alloy melting device,

[0027] Including a melting furnace, the melting furnace includes a furnace body 1 and a graphite crucible 2, the graphite crucible 2 is arranged inside the furnace body 1, and the lower side of the furnace body 1 is provided with a base 3;

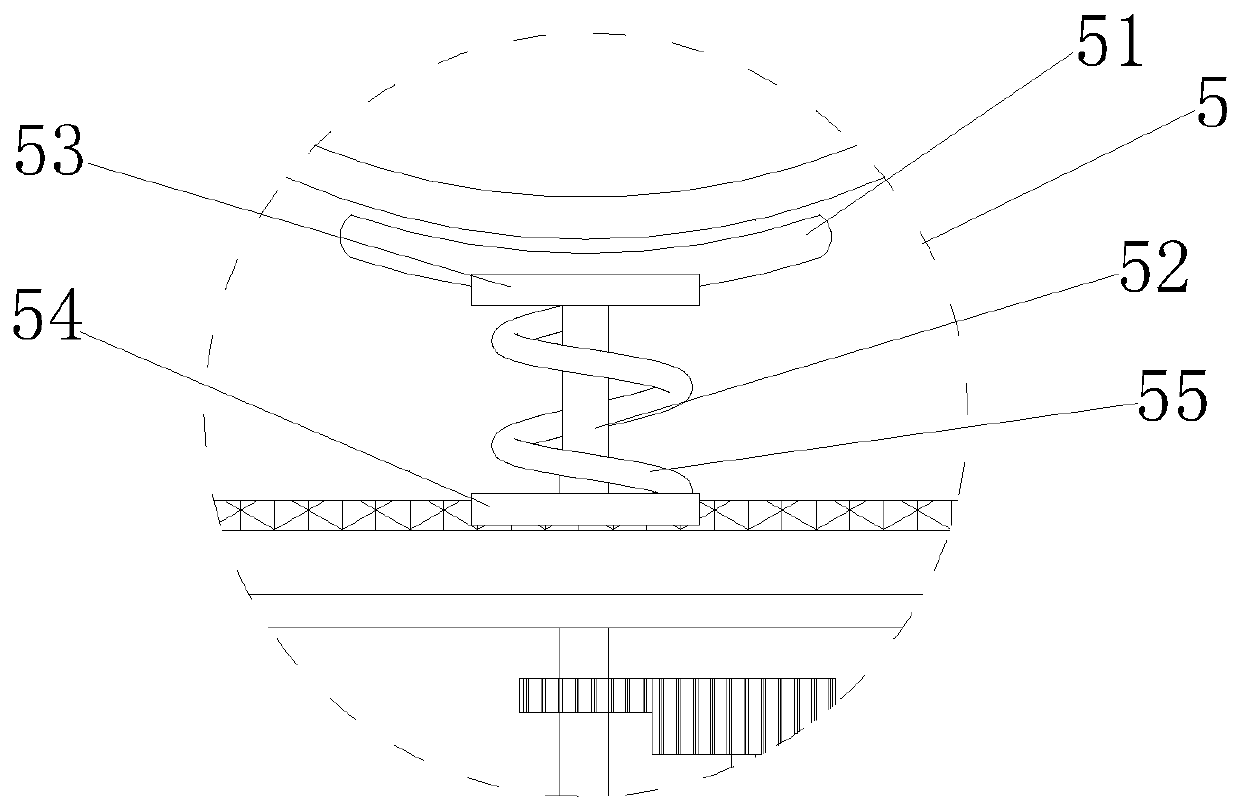

[0028] The outer side of the graphite crucible 2 is covered with a heating jacket 4, the lower side of the graphite crucible 2 is provided with a support frame 5, the upper side of the support frame 5 is supported on the lower side of the graphite crucible 2, and the support frame 5 The lower side of the bottom is provided with a driving device 6 for driving the rotation of the support frame 5, and the driving device 6 is arranged in the base 3;

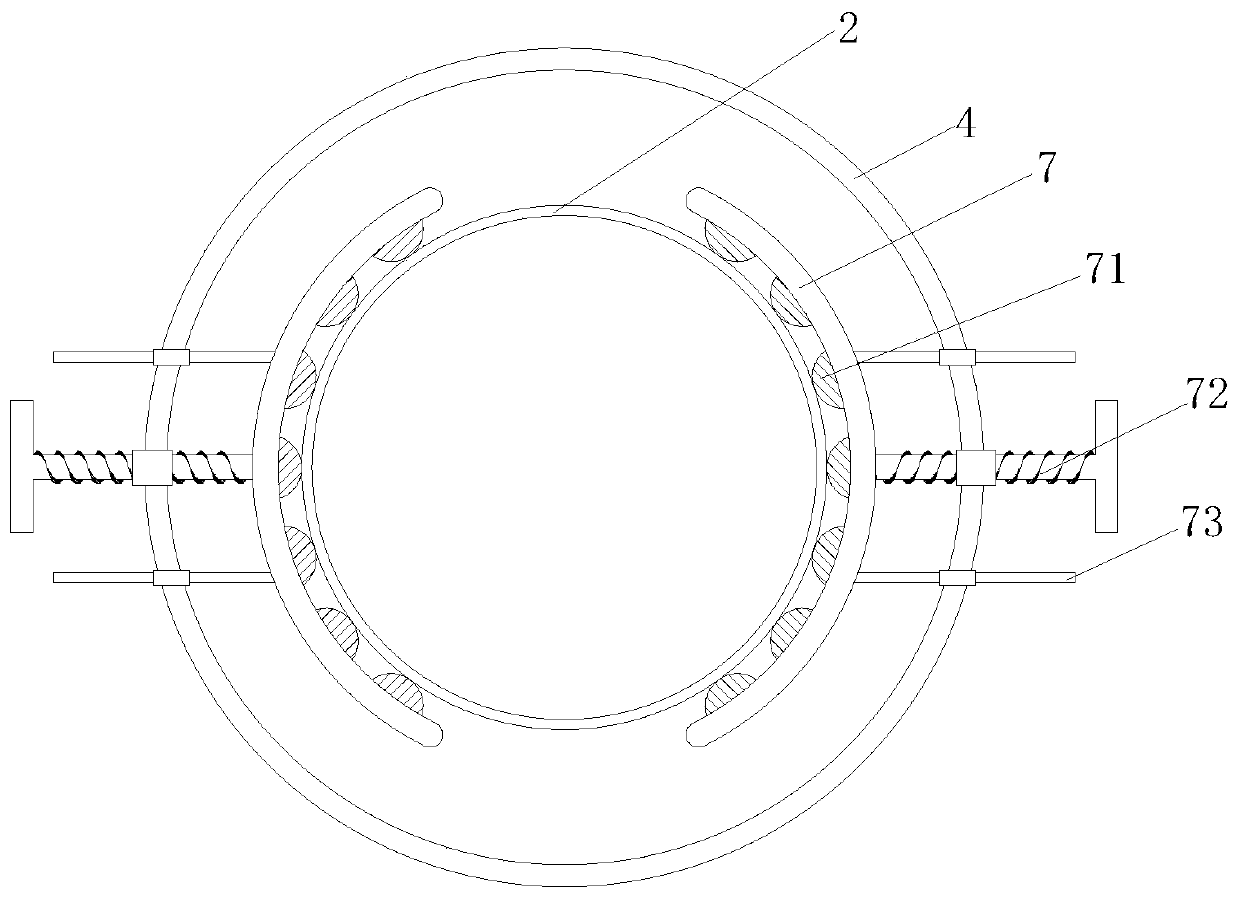

[0029] Such as figure 2 As shown: the side wall of the graphite crucible 2 is provided with a plurality of arc-shaped clamping arms 7, the clamping arms 7 match the arc shape of the side wall of the graphite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com